Kevlar fabric and Kevlar felt both offer exceptional strength and durability, but differ significantly in texture and application. Kevlar fabric is tightly woven, providing superior tensile strength and abrasion resistance, making it ideal for protective gear and high-impact environments. Kevlar felt is non-woven, softer, and more flexible, commonly used for insulation and padding where lightweight protection is required.

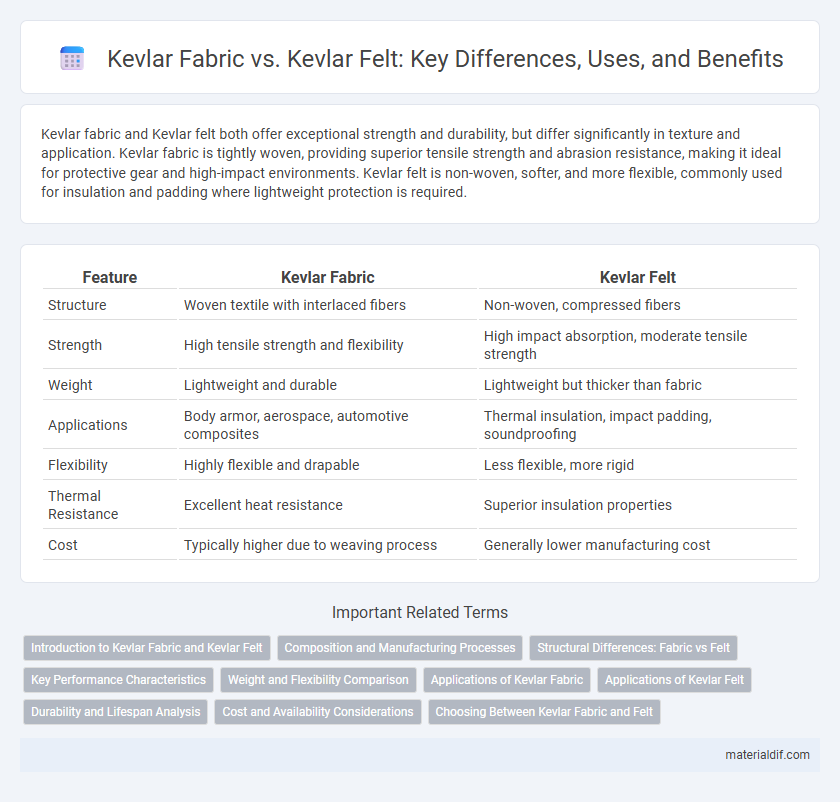

Table of Comparison

| Feature | Kevlar Fabric | Kevlar Felt |

|---|---|---|

| Structure | Woven textile with interlaced fibers | Non-woven, compressed fibers |

| Strength | High tensile strength and flexibility | High impact absorption, moderate tensile strength |

| Weight | Lightweight and durable | Lightweight but thicker than fabric |

| Applications | Body armor, aerospace, automotive composites | Thermal insulation, impact padding, soundproofing |

| Flexibility | Highly flexible and drapable | Less flexible, more rigid |

| Thermal Resistance | Excellent heat resistance | Superior insulation properties |

| Cost | Typically higher due to weaving process | Generally lower manufacturing cost |

Introduction to Kevlar Fabric and Kevlar Felt

Kevlar fabric is a woven material made from high-strength aramid fibers, known for its exceptional tensile strength, durability, and resistance to abrasion, commonly used in protective gear and aerospace applications. Kevlar felt, on the other hand, is a non-woven, matted version of Kevlar fibers, offering enhanced thermal insulation and cushioning properties, often utilized in soundproofing and padding. Both materials leverage Kevlar's inherent toughness but differ significantly in texture and specific use cases, with fabric providing structural integrity and felt delivering shock absorption.

Composition and Manufacturing Processes

Kevlar fabric consists of woven aramid fibers arranged in a tight, flexible textile, providing high tensile strength and durability ideal for protective gear and composite reinforcements. Kevlar felt, by contrast, is a non-woven material created by bonding aramid fibers into a dense mat through needle punching or resin impregnation, resulting in a thicker, less flexible structure with excellent thermal insulation and impact absorption. The distinct manufacturing processes influence their performance characteristics, with Kevlar fabric offering superior flexibility and Kevlar felt delivering enhanced padding and protection in applications like ballistic armor and heat shields.

Structural Differences: Fabric vs Felt

Kevlar fabric consists of tightly woven fibers arranged in a crisscross pattern, providing high tensile strength and durability ideal for ballistic and protective applications. Kevlar felt, on the other hand, is made from loosely matted fibers compressed into a dense sheet, offering superior flexibility and impact absorption. The structural difference between woven fabric and non-woven felt influences their use cases, with fabric excelling in resistance to penetration and felt favored for cushioning and heat insulation.

Key Performance Characteristics

Kevlar fabric offers high tensile strength and excellent flexibility, making it ideal for applications requiring durability and abrasion resistance, such as body armor and protective clothing. Kevlar felt provides superior insulation, impact absorption, and thermal resistance, often used in industrial settings for heat shielding and padding. Both materials exhibit impressive chemical resistance, but Kevlar fabric excels in structural integrity while Kevlar felt specializes in cushioning and thermal protection.

Weight and Flexibility Comparison

Kevlar fabric is lighter and exhibits higher flexibility compared to Kevlar felt, making it suitable for applications requiring ease of movement and reduced weight. Kevlar felt, being denser and thicker, offers enhanced padding and thermal insulation but at the cost of increased weight and reduced flexibility. The choice between Kevlar fabric and felt depends largely on the balance needed between mobility and protection in specific use cases.

Applications of Kevlar Fabric

Kevlar fabric is highly valued in industries requiring superior strength and durability, such as aerospace, military, and automotive sectors, where it is used for ballistic vests, helmets, and reinforcement panels. Its woven structure provides excellent tensile strength and flexibility, making it ideal for protective clothing and composite materials that demand high-performance impact resistance. Kevlar felt, by contrast, is commonly utilized for thermal insulation and gasketing due to its non-woven fibrous form, prioritizing heat resistance over tensile strength.

Applications of Kevlar Felt

Kevlar Felt is widely used in applications requiring impact resistance, sound dampening, and thermal insulation, such as automotive brake pads, gaskets, and protective padding in industrial settings. Unlike Kevlar Fabric, which is woven for tensile strength and flexibility in body armor and aerospace components, Kevlar Felt offers a dense, non-woven structure that provides cushioning and vibration absorption in heavy machinery and protective equipment. Its unique fiber bonding makes it ideal for high-performance applications where durability and shock mitigation are critical.

Durability and Lifespan Analysis

Kevlar fabric offers superior tensile strength and abrasion resistance compared to Kevlar felt, making it more durable for applications requiring high impact and wear resistance. Kevlar felt, with its dense fiber structure, excels in vibration dampening and thermal insulation but generally has a shorter lifespan under continuous mechanical stress. The lifespan of Kevlar fabric can extend up to 8-10 years in demanding environments, while Kevlar felt typically lasts 3-5 years before significant degradation occurs.

Cost and Availability Considerations

Kevlar fabric generally costs more than Kevlar felt due to its woven structure, which requires more complex manufacturing processes and higher material precision. Kevlar felt tends to be more readily available and cost-effective for large-area applications where uniform strength and flexibility are less critical. Availability of Kevlar fabric can be limited by supplier capacity and demand in industries like aerospace and protective gear, while Kevlar felt is commonly stocked for industrial filtration and thermal insulation uses.

Choosing Between Kevlar Fabric and Felt

Kevlar fabric offers high tensile strength and flexibility, making it ideal for applications requiring durability and abrasion resistance, such as body armor and composite reinforcements. Kevlar felt, characterized by its thicker, non-woven structure, provides enhanced thermal insulation and impact absorption, suited for padding and protective liners. Selecting between Kevlar fabric and felt depends on the specific need for structural strength versus cushioning and thermal properties.

Kevlar Fabric vs Kevlar Felt Infographic

materialdif.com

materialdif.com