Kevlar coating offers superior durability and puncture resistance compared to polyurethane coating, making it ideal for pet products exposed to rough use and sharp objects. While polyurethane provides a flexible and waterproof layer, Kevlar enhances strength and longevity without compromising comfort. Choosing Kevlar coating ensures enhanced protection and extended lifespan for pet gear in demanding environments.

Table of Comparison

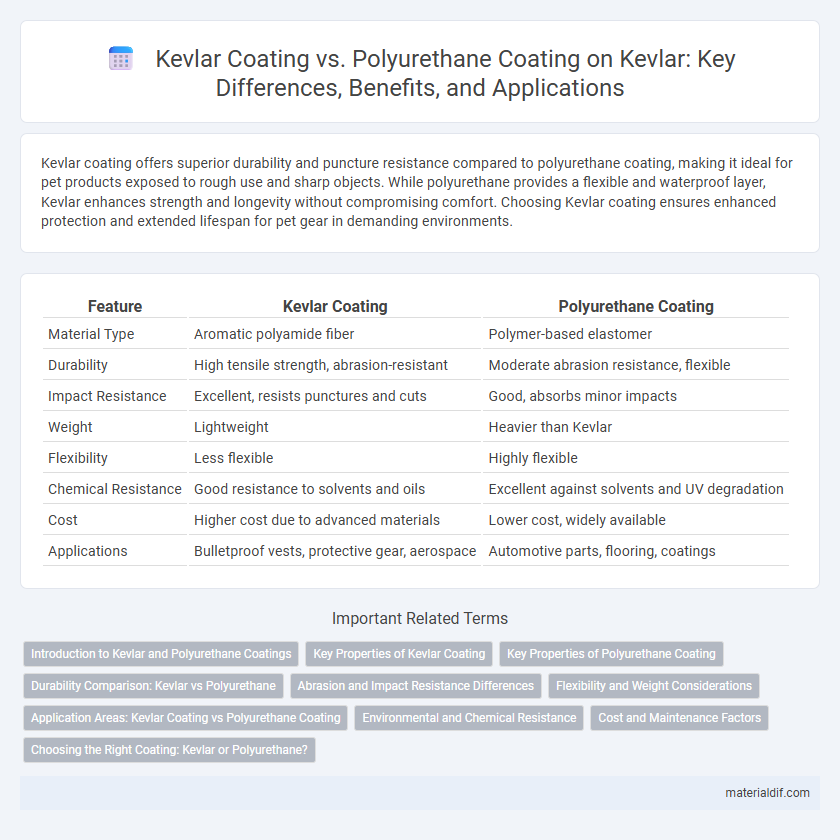

| Feature | Kevlar Coating | Polyurethane Coating |

|---|---|---|

| Material Type | Aromatic polyamide fiber | Polymer-based elastomer |

| Durability | High tensile strength, abrasion-resistant | Moderate abrasion resistance, flexible |

| Impact Resistance | Excellent, resists punctures and cuts | Good, absorbs minor impacts |

| Weight | Lightweight | Heavier than Kevlar |

| Flexibility | Less flexible | Highly flexible |

| Chemical Resistance | Good resistance to solvents and oils | Excellent against solvents and UV degradation |

| Cost | Higher cost due to advanced materials | Lower cost, widely available |

| Applications | Bulletproof vests, protective gear, aerospace | Automotive parts, flooring, coatings |

Introduction to Kevlar and Polyurethane Coatings

Kevlar coatings provide exceptional abrasion resistance and high tensile strength, making them ideal for protective gear and industrial applications requiring durability. Polyurethane coatings offer flexibility, UV resistance, and chemical protection, commonly used in automotive finishes and flooring. Both coatings serve distinct purposes depending on the required balance between toughness and elasticity.

Key Properties of Kevlar Coating

Kevlar coating offers exceptional tensile strength and high resistance to impact, making it ideal for protective applications in aerospace and body armor. Its superior thermal stability and chemical resistance outperform polyurethane coatings, which are more prone to degradation under extreme conditions. Kevlar's lightweight nature combined with its durability ensures enhanced protection without significantly increasing the overall weight of the coated material.

Key Properties of Polyurethane Coating

Polyurethane coating offers exceptional abrasion resistance and flexibility, making it an ideal protective layer for Kevlar materials used in high-wear applications. This coating provides excellent UV stability and chemical resistance, enhancing the durability and longevity of Kevlar fibers exposed to harsh environmental conditions. Its strong adhesive properties ensure a robust bond with Kevlar substrates, maintaining performance integrity under mechanical stress.

Durability Comparison: Kevlar vs Polyurethane

Kevlar coating exhibits exceptional durability due to its high tensile strength and resistance to abrasion, outperforming polyurethane coatings in harsh environments. While polyurethane offers flexibility and UV resistance, it tends to degrade faster under extreme mechanical stress compared to Kevlar's robust fiber matrix. Kevlar's superior impact resistance and long-lasting protective qualities make it ideal for applications demanding enhanced durability and longevity.

Abrasion and Impact Resistance Differences

Kevlar coating provides superior abrasion resistance due to its high tensile strength and fiber structure, making it ideal for applications requiring durable protection against wear and tear. Polyurethane coating offers excellent impact resistance with its flexible and resilient polymer matrix, absorbing shocks and preventing surface damage effectively. Comparing both, Kevlar excels in maintaining structural integrity under continuous friction, while polyurethane better protects surfaces from sudden impacts.

Flexibility and Weight Considerations

Kevlar coating offers superior flexibility compared to polyurethane coating, making it ideal for applications requiring movement and impact resistance without compromising durability. Kevlar's lightweight nature enhances its performance in weight-sensitive settings such as aerospace and sports equipment. Polyurethane coatings tend to be heavier and less flexible, which can limit their use in dynamic environments where both flexibility and weight are critical factors.

Application Areas: Kevlar Coating vs Polyurethane Coating

Kevlar coating excels in high-performance applications requiring exceptional abrasion resistance and impact protection, making it ideal for military gear, ballistic armor, and aerospace components. Polyurethane coating is widely used in automotive, marine, and industrial sectors due to its flexibility, UV resistance, and excellent weatherproofing properties. Both coatings serve distinct roles, with Kevlar favored for durability in extreme conditions while polyurethane provides versatile protection in environments exposed to moisture and chemicals.

Environmental and Chemical Resistance

Kevlar coatings exhibit superior chemical resistance, effectively withstanding exposure to strong acids, bases, and solvents without degradation, which makes them ideal for harsh industrial environments. Polyurethane coatings offer excellent environmental resistance by providing robust protection against UV radiation, moisture, and abrasion but may be less resistant to aggressive chemicals compared to Kevlar. The combination of Kevlar's chemical resilience and polyurethane's environmental durability supports enhanced longevity in protective applications exposed to varying conditions.

Cost and Maintenance Factors

Kevlar coating offers superior durability and resistance to abrasion but comes with a higher initial cost compared to polyurethane coating, which is more budget-friendly yet less resistant to wear. Maintenance for Kevlar coatings is minimal due to their strong structural integrity, reducing long-term expenses, while polyurethane coatings require more frequent touch-ups and repairs to maintain effectiveness. Cost-efficiency in the long run favors Kevlar despite its upfront price, making it ideal for applications demanding high performance and low upkeep.

Choosing the Right Coating: Kevlar or Polyurethane?

Kevlar coating offers superior abrasion resistance and high tensile strength, making it ideal for applications requiring enhanced durability and protection against impact or heat. Polyurethane coating provides excellent flexibility, UV resistance, and moisture protection, suited for environments where elasticity and weather resistance are crucial. Selecting between Kevlar and polyurethane coatings depends on specific performance needs such as durability versus flexibility and exposure conditions.

Kevlar Coating vs Polyurethane Coating Infographic

materialdif.com

materialdif.com