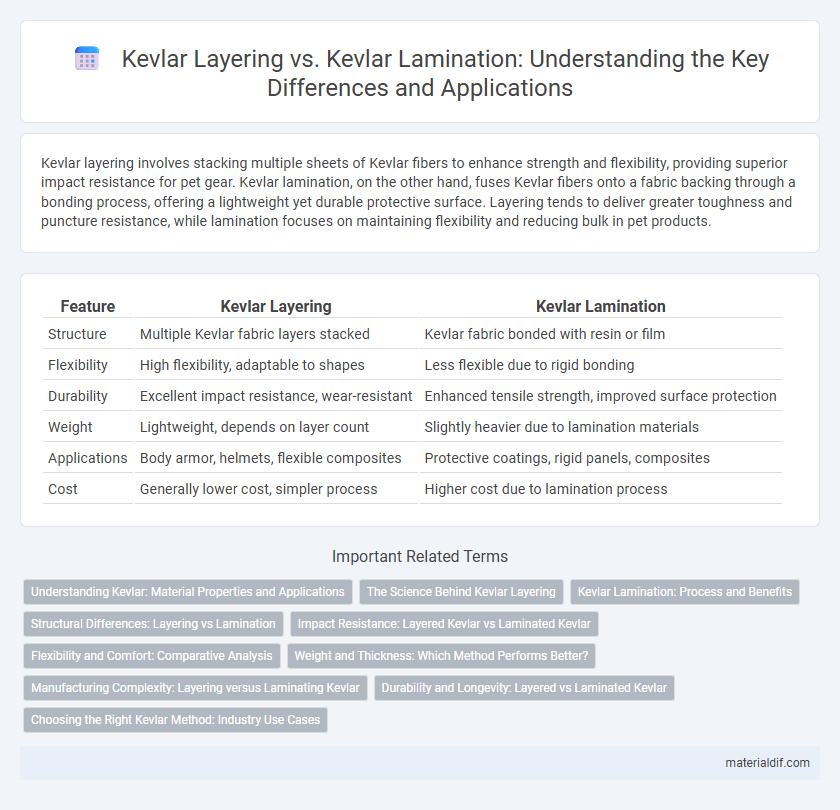

Kevlar layering involves stacking multiple sheets of Kevlar fibers to enhance strength and flexibility, providing superior impact resistance for pet gear. Kevlar lamination, on the other hand, fuses Kevlar fibers onto a fabric backing through a bonding process, offering a lightweight yet durable protective surface. Layering tends to deliver greater toughness and puncture resistance, while lamination focuses on maintaining flexibility and reducing bulk in pet products.

Table of Comparison

| Feature | Kevlar Layering | Kevlar Lamination |

|---|---|---|

| Structure | Multiple Kevlar fabric layers stacked | Kevlar fabric bonded with resin or film |

| Flexibility | High flexibility, adaptable to shapes | Less flexible due to rigid bonding |

| Durability | Excellent impact resistance, wear-resistant | Enhanced tensile strength, improved surface protection |

| Weight | Lightweight, depends on layer count | Slightly heavier due to lamination materials |

| Applications | Body armor, helmets, flexible composites | Protective coatings, rigid panels, composites |

| Cost | Generally lower cost, simpler process | Higher cost due to lamination process |

Understanding Kevlar: Material Properties and Applications

Kevlar layering involves stacking multiple sheets of Kevlar fabric to enhance tensile strength and impact resistance, making it ideal for body armor and sports equipment. Kevlar lamination bonds these layers with adhesives or resins, improving flexibility and durability while maintaining lightweight properties critical in aerospace and automotive industries. Understanding the distinct roles of layering and lamination helps optimize Kevlar's performance in diverse applications requiring high strength-to-weight ratios and abrasion resistance.

The Science Behind Kevlar Layering

Kevlar layering involves stacking multiple sheets of Kevlar fibers oriented in specific directions to enhance tensile strength and impact resistance through mechanical reinforcement. The unique molecular structure of Kevlar, with its para-aramid polymer chains, allows each layer to distribute stress effectively, increasing durability and flexibility. This layering technique optimizes energy absorption and fracture toughness by leveraging the interfacial bonding between layers without compromising the material's lightweight properties.

Kevlar Lamination: Process and Benefits

Kevlar lamination involves bonding multiple Kevlar layers with resin or adhesive films under heat and pressure, creating a unified composite material with enhanced strength and durability. This process improves impact resistance, flexibility, and weight efficiency compared to traditional layering, making laminated Kevlar ideal for ballistic armor, aerospace, and automotive applications. The uniform bonding in lamination reduces delamination risks and increases structural integrity in demanding environments.

Structural Differences: Layering vs Lamination

Kevlar layering involves stacking multiple woven or non-woven Kevlar fabric sheets, enhancing tensile strength and flexibility through mechanical interlocking of fibers. Kevlar lamination, by contrast, embeds Kevlar layers within polymer matrices using adhesives or heat, creating a unified composite that improves impact resistance and rigidity. The primary structural difference is layering relies on fabric stacking without bonding agents, while lamination fuses layers for integrated load distribution and durability.

Impact Resistance: Layered Kevlar vs Laminated Kevlar

Layered Kevlar consists of multiple woven sheets stacked to enhance flexibility and energy absorption, providing superior impact resistance by dispersing forces across individual layers. Laminated Kevlar integrates resin or adhesive between layers, creating a rigid, unified structure that improves stiffness but may reduce the material's ability to flex under impact. For applications demanding maximum impact resistance and trauma dispersion, layered Kevlar outperforms laminated Kevlar by maintaining structural integrity while allowing controlled deformation.

Flexibility and Comfort: Comparative Analysis

Kevlar layering involves stacking multiple woven Kevlar fabrics, creating a flexible structure that adapts better to body movements, enhancing wearer comfort in protective gear. Kevlar lamination, by bonding Kevlar sheets with resin or polymer films, often results in a stiffer material that may reduce flexibility but increases impact resistance. Comparing the two, Kevlar layering prioritizes comfort and flexibility for dynamic use, while lamination offers improved protection at the cost of reduced mobility.

Weight and Thickness: Which Method Performs Better?

Kevlar layering typically results in increased thickness and weight due to multiple overlapping fabric plies, which can enhance impact resistance but may reduce flexibility. Kevlar lamination, by bonding thinner Kevlar sheets with adhesives or resins, achieves a lighter and thinner composite while maintaining comparable strength and durability. Weight-sensitive applications often benefit more from lamination, whereas layering is preferred where maximum protection and rigidity are critical.

Manufacturing Complexity: Layering versus Laminating Kevlar

Kevlar layering involves stacking multiple fabric sheets to achieve desired thickness, requiring precise alignment and secure bonding to maintain structural integrity. Kevlar lamination integrates layers using resin or adhesive films under heat and pressure, creating a unified, often more flexible composite with increased resistance to environmental factors. Compared to layering, lamination demands sophisticated equipment and controlled conditions, making the manufacturing process more complex but resulting in enhanced material performance.

Durability and Longevity: Layered vs Laminated Kevlar

Layered Kevlar enhances durability by multiple overlapping fibers that distribute impact forces and prevent delamination, resulting in superior longevity under repeated stress. Laminated Kevlar, bonded with resins or films, offers rigidity but may face reduced durability over time due to potential layer separation or matrix degradation under harsh conditions. For applications demanding extended service life and high-impact resistance, layered Kevlar structures generally outperform laminated alternatives in maintaining integrity.

Choosing the Right Kevlar Method: Industry Use Cases

Kevlar layering involves stacking multiple Kevlar fabric plies to enhance impact resistance and flexibility, commonly applied in ballistic armor for law enforcement and military gear. Kevlar lamination fuses Kevlar fibers with resin or films, producing rigid, lightweight panels ideal for aerospace components and automotive body armor. Selecting the right method depends on application requirements such as flexibility, weight constraints, and environmental exposure in industries like defense, aerospace, and automotive manufacturing.

Kevlar Layering vs Kevlar Lamination Infographic

materialdif.com

materialdif.com