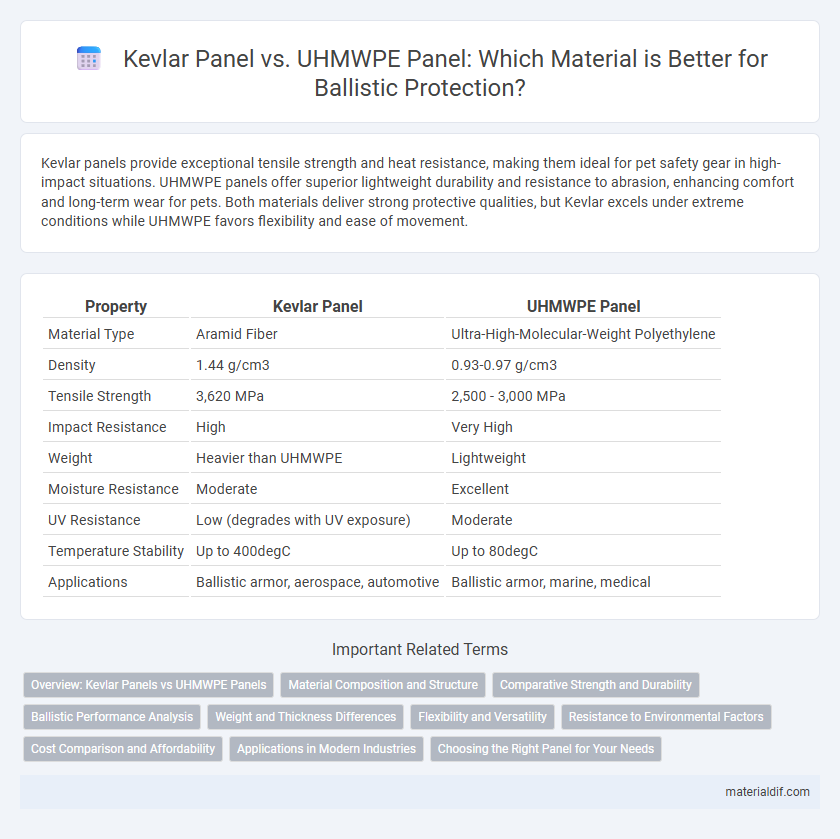

Kevlar panels provide exceptional tensile strength and heat resistance, making them ideal for pet safety gear in high-impact situations. UHMWPE panels offer superior lightweight durability and resistance to abrasion, enhancing comfort and long-term wear for pets. Both materials deliver strong protective qualities, but Kevlar excels under extreme conditions while UHMWPE favors flexibility and ease of movement.

Table of Comparison

| Property | Kevlar Panel | UHMWPE Panel |

|---|---|---|

| Material Type | Aramid Fiber | Ultra-High-Molecular-Weight Polyethylene |

| Density | 1.44 g/cm3 | 0.93-0.97 g/cm3 |

| Tensile Strength | 3,620 MPa | 2,500 - 3,000 MPa |

| Impact Resistance | High | Very High |

| Weight | Heavier than UHMWPE | Lightweight |

| Moisture Resistance | Moderate | Excellent |

| UV Resistance | Low (degrades with UV exposure) | Moderate |

| Temperature Stability | Up to 400degC | Up to 80degC |

| Applications | Ballistic armor, aerospace, automotive | Ballistic armor, marine, medical |

Overview: Kevlar Panels vs UHMWPE Panels

Kevlar panels provide exceptional tensile strength and impact resistance due to their aramid fiber composition, making them highly effective in ballistic protection and cut resistance. UHMWPE panels, made from ultra-high-molecular-weight polyethylene fibers, offer lighter weight and superior chemical and moisture resistance, enhancing durability in harsh environments. Both materials excel in body armor applications, with Kevlar offering better thermal stability and UHMWPE delivering enhanced blunt force trauma mitigation through higher energy absorption.

Material Composition and Structure

Kevlar panels are composed of para-aramid synthetic fibers known for high tensile strength and heat resistance, arranged in a tightly woven, fibrous matrix to provide excellent ballistic protection and durability. UHMWPE (Ultra-High-Molecular-Weight Polyethylene) panels consist of extremely long polyethylene chains aligned in a highly crystalline structure, resulting in lightweight, high-impact resistance with superior energy absorption. The distinct molecular composition and fiber arrangement of Kevlar offers more rigidity, while UHMWPE provides enhanced flexibility and lower density for improved wearability in armor applications.

Comparative Strength and Durability

Kevlar panels exhibit superior tensile strength, boasting a tensile strength of approximately 3,620 MPa compared to UHMWPE panels, which typically measure around 2,770 MPa. Kevlar also maintains structural integrity under high temperatures up to 450degC, whereas UHMWPE panels degrade above 80degC, limiting their thermal durability. The enhanced impact resistance and abrasion resistance make Kevlar panels more durable for ballistic protection and harsh operational environments than UHMWPE alternatives.

Ballistic Performance Analysis

Kevlar panels exhibit high tensile strength and excellent energy absorption, making them effective in dissipating ballistic impacts. UHMWPE panels offer superior ballistic performance due to their lower density and higher tensile modulus, resulting in enhanced multi-hit resistance and reduced backface deformation. Comparative studies demonstrate UHMWPE panels generally outperform Kevlar in stopping power and weight efficiency for ballistic protection applications.

Weight and Thickness Differences

Kevlar panels typically offer a balance of lightweight protection with moderate thickness, making them ideal for applications requiring flexibility and durability. UHMWPE panels are generally lighter than Kevlar while providing similar or better ballistic resistance, allowing for reduced weight in body armor and vehicle protection systems. Thickness differences show UHMWPE panels are often thinner, enhancing wearer comfort and mobility without compromising strength.

Flexibility and Versatility

Kevlar panels exhibit exceptional flexibility due to their woven aramid fiber structure, allowing them to conform well to various shapes and movements without compromising protective integrity. In contrast, UHMWPE panels, made from ultra-high-molecular-weight polyethylene fibers, offer greater rigidity but excel in lightweight applications, making them less adaptable in complex designs. The versatility of Kevlar panels makes them ideal for body armor and ballistic protection requiring both durability and flexibility across multiple environments.

Resistance to Environmental Factors

Kevlar panels exhibit superior resistance to heat and chemical exposure compared to UHMWPE panels, maintaining structural integrity under high temperatures up to 450degC. UHMWPE panels, while offering excellent impact resistance, degrade more rapidly when exposed to UV radiation and prolonged moisture. The inherent thermal stability and chemical resistance of Kevlar make it more suitable for environments with extreme and fluctuating conditions.

Cost Comparison and Affordability

Kevlar panels typically cost more than UHMWPE panels due to the complex aramid fiber manufacturing process, impacting overall affordability for large-scale use. UHMWPE panels offer a more budget-friendly alternative with lower production costs and comparable ballistic protection in certain applications. Cost efficiency of UHMWPE enhances its appeal for industries prioritizing both performance and economical solutions in protective armor.

Applications in Modern Industries

Kevlar panels offer superior ballistic resistance and thermal stability, making them ideal for military armor, aerospace components, and automotive safety applications. UHMWPE panels provide lightweight, high-strength protection with excellent resistance to chemical corrosion, commonly used in personal body armor, marine vessels, and industrial protective gear. Both materials are essential in modern industries where durability, impact resistance, and weight reduction are critical factors.

Choosing the Right Panel for Your Needs

Kevlar panels offer excellent tensile strength and resistance to heat, making them ideal for applications requiring durability in extreme conditions, while UHMWPE panels provide superior impact resistance and lightweight protection suitable for ballistic and stab-resistant gear. When choosing between Kevlar and UHMWPE panels, consider factors such as weight, flexibility, and threat level, as UHMWPE tends to be lighter but less heat-resistant compared to Kevlar. Assessing the specific operational environment and protection requirements ensures the selection of the most effective panel material for your needs.

Kevlar panel vs UHMWPE panel Infographic

materialdif.com

materialdif.com