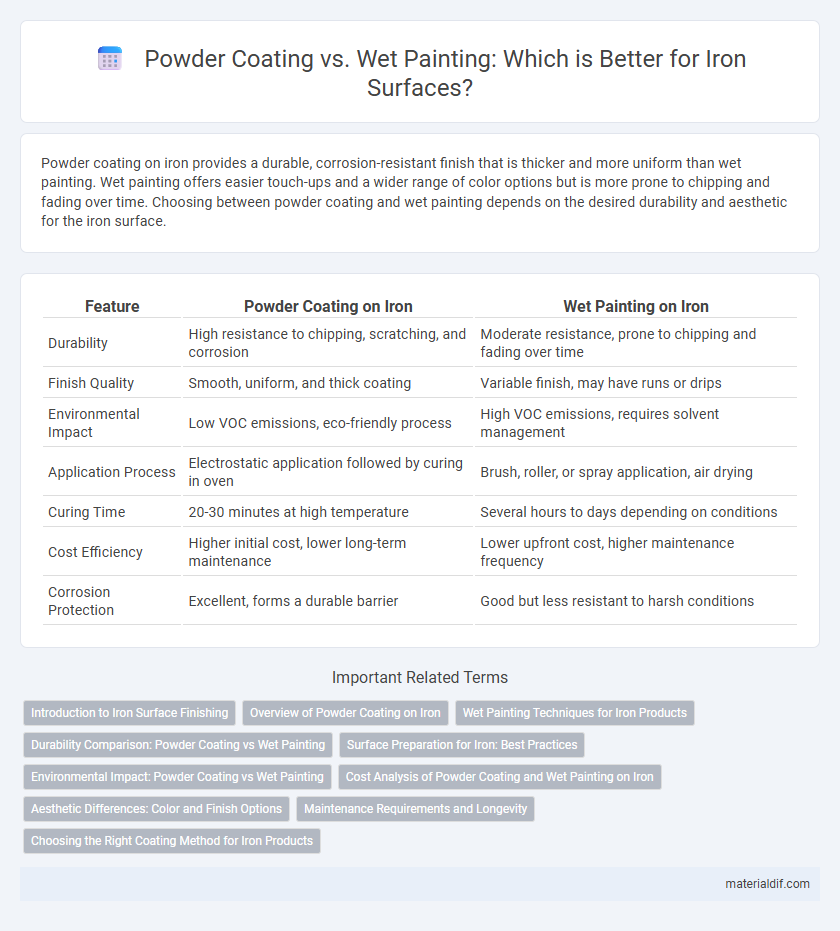

Powder coating on iron provides a durable, corrosion-resistant finish that is thicker and more uniform than wet painting. Wet painting offers easier touch-ups and a wider range of color options but is more prone to chipping and fading over time. Choosing between powder coating and wet painting depends on the desired durability and aesthetic for the iron surface.

Table of Comparison

| Feature | Powder Coating on Iron | Wet Painting on Iron |

|---|---|---|

| Durability | High resistance to chipping, scratching, and corrosion | Moderate resistance, prone to chipping and fading over time |

| Finish Quality | Smooth, uniform, and thick coating | Variable finish, may have runs or drips |

| Environmental Impact | Low VOC emissions, eco-friendly process | High VOC emissions, requires solvent management |

| Application Process | Electrostatic application followed by curing in oven | Brush, roller, or spray application, air drying |

| Curing Time | 20-30 minutes at high temperature | Several hours to days depending on conditions |

| Cost Efficiency | Higher initial cost, lower long-term maintenance | Lower upfront cost, higher maintenance frequency |

| Corrosion Protection | Excellent, forms a durable barrier | Good but less resistant to harsh conditions |

Introduction to Iron Surface Finishing

Iron surface finishing techniques such as powder coating and wet painting provide essential protection against corrosion and enhance durability. Powder coating involves applying a dry powder that is cured under heat, creating a robust, uniform, and long-lasting finish ideal for outdoor and industrial applications. Wet painting uses liquid paint applied with brushes or spray equipment, offering versatile color options but requiring more frequent maintenance due to lower resistance to chipping and environmental wear.

Overview of Powder Coating on Iron

Powder coating on iron provides a durable, corrosion-resistant finish that significantly extends the lifespan of iron components compared to traditional wet painting. This dry finishing process involves applying a free-flowing, electrostatically charged powder that is then cured under heat, resulting in a smooth, uniform coating with superior adhesion. The method is environmentally friendly, emitting negligible volatile organic compounds (VOCs), and offers excellent resistance to chipping, scratching, and fading.

Wet Painting Techniques for Iron Products

Wet painting techniques for iron products involve applying liquid paint directly to the surface, allowing for deeper penetration into the metal pores and creating a protective barrier against corrosion. Common methods include spray, brush, and roller applications, each offering versatility in coating thickness and finish quality. Proper surface preparation and curing conditions are essential to enhance adhesion, durability, and resistance to environmental factors in wet-painted iron products.

Durability Comparison: Powder Coating vs Wet Painting

Powder coating on iron provides superior durability compared to wet painting, offering enhanced resistance to chipping, scratching, and corrosion. The thermoset polymer process creates a thicker, more uniform layer that withstands harsh weather and chemical exposure better than traditional liquid paint. Wet painting tends to wear faster and requires more frequent maintenance due to its thinner application and susceptibility to environmental damage.

Surface Preparation for Iron: Best Practices

Effective surface preparation for iron involves thorough cleaning to remove rust, grease, and contaminants using methods like sandblasting or chemical treatments. For powder coating, the surface must be completely dry and free of moisture to ensure proper adhesion and durability. In wet painting, applying a primer after cleaning enhances corrosion resistance and promotes better paint bonding on iron surfaces.

Environmental Impact: Powder Coating vs Wet Painting

Powder coating on iron offers a lower environmental impact due to its minimal volatile organic compound (VOC) emissions compared to wet painting, which releases significant VOCs contributing to air pollution and health hazards. The overspray in powder coating can be recycled, reducing waste, whereas wet paint results in more hazardous waste and solvent disposal issues. Energy efficiency also favors powder coating, as it typically cures faster and uses less energy, decreasing the overall carbon footprint.

Cost Analysis of Powder Coating and Wet Painting on Iron

Powder coating on iron typically offers lower long-term costs due to its durability and reduced maintenance requirements, despite a higher initial investment in equipment. Wet painting on iron generally has lower upfront expenses but incurs higher costs over time from frequent recoating and labor. Analyzing total costs reveals powder coating's efficiency and cost-effectiveness in large-scale or industrial iron applications.

Aesthetic Differences: Color and Finish Options

Powder coating on iron offers a wide spectrum of vibrant, uniform color options with a durable, smooth, and glossy finish that resists chipping and fading. Wet painting allows for more customizable finishes, including matte, satin, and gloss, but may require additional maintenance to prevent peeling or discoloration. The choice between powder coating and wet painting significantly impacts the aesthetic durability and color consistency of iron surfaces.

Maintenance Requirements and Longevity

Powder coating on iron offers superior maintenance benefits, resisting chipping, fading, and corrosion better than wet painting, which generally requires more frequent touch-ups and repainting due to susceptibility to moisture and wear. The longevity of powder-coated iron surfaces typically exceeds 10-15 years under harsh environmental conditions, whereas wet-painted iron may last around 5-7 years before significant deterioration occurs. Choosing powder coating minimizes long-term maintenance costs and ensures a durable, weather-resistant finish on iron structures.

Choosing the Right Coating Method for Iron Products

Powder coating provides a durable, corrosion-resistant finish that is ideal for iron products exposed to harsh environments, ensuring long-lasting protection and minimal maintenance. Wet painting offers more flexibility in color matching and is suitable for intricate iron designs where a smooth, thin coat is required. Selecting the right coating depends on the iron product's usage, environmental exposure, and desired aesthetic, with powder coating favored for industrial durability and wet painting preferred for detailed or touch-up applications.

Powder Coating vs Wet Painting (on Iron) Infographic

materialdif.com

materialdif.com