Galvanized iron is coated with a layer of zinc to protect it from rust and corrosion, making it ideal for outdoor and industrial applications. Non-galvanized iron, lacking this protective coating, is more prone to oxidization and suitable for indoor use where exposure to moisture is minimal. Choosing between galvanized and non-galvanized iron depends on the specific environmental conditions and durability requirements of the project.

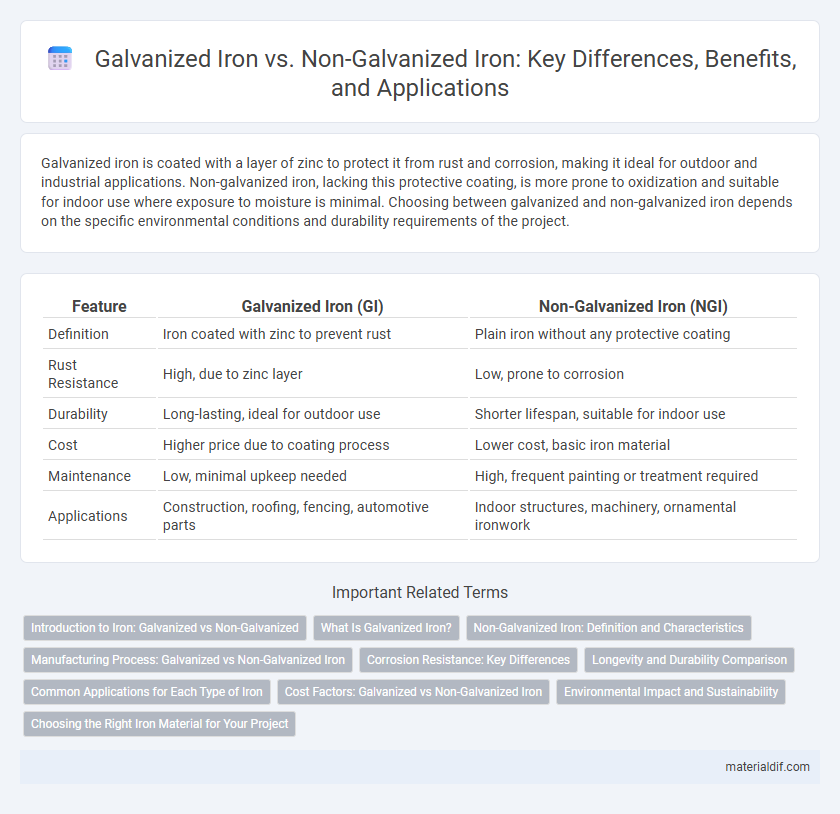

Table of Comparison

| Feature | Galvanized Iron (GI) | Non-Galvanized Iron (NGI) |

|---|---|---|

| Definition | Iron coated with zinc to prevent rust | Plain iron without any protective coating |

| Rust Resistance | High, due to zinc layer | Low, prone to corrosion |

| Durability | Long-lasting, ideal for outdoor use | Shorter lifespan, suitable for indoor use |

| Cost | Higher price due to coating process | Lower cost, basic iron material |

| Maintenance | Low, minimal upkeep needed | High, frequent painting or treatment required |

| Applications | Construction, roofing, fencing, automotive parts | Indoor structures, machinery, ornamental ironwork |

Introduction to Iron: Galvanized vs Non-Galvanized

Galvanized iron is coated with a layer of zinc to enhance corrosion resistance, making it ideal for outdoor and industrial applications. Non-galvanized iron lacks this protective layer, rendering it more susceptible to rust but often preferred for indoor uses where corrosion is minimal. The choice between galvanized and non-galvanized iron depends on environmental exposure and longevity requirements.

What Is Galvanized Iron?

Galvanized iron is steel or iron coated with a protective layer of zinc to prevent rusting and corrosion, significantly enhancing its durability in outdoor and industrial applications. The zinc coating acts as a sacrificial anode, protecting the underlying metal even if the coating is scratched or damaged. This makes galvanized iron ideal for construction, roofing, and automotive parts where exposure to moisture and harsh environments is common.

Non-Galvanized Iron: Definition and Characteristics

Non-galvanized iron refers to iron that has not undergone the galvanization process, leaving it vulnerable to rust and corrosion when exposed to moisture and air. It typically has a raw, dark gray surface and requires protective coatings like paint or oil to enhance durability. Commonly used in construction and manufacturing, non-galvanized iron is preferred where cost efficiency is crucial and corrosion resistance is less critical.

Manufacturing Process: Galvanized vs Non-Galvanized Iron

Galvanized iron undergoes a manufacturing process where a protective zinc coating is applied through hot-dip galvanizing or electro-galvanizing, enhancing its corrosion resistance. Non-galvanized iron is processed without this zinc layer, leaving the metal more susceptible to rust and environmental degradation. The galvanizing process involves immersing iron in molten zinc, creating a strong metallurgical bond that extends the iron's durability significantly compared to untreated iron.

Corrosion Resistance: Key Differences

Galvanized iron features a protective zinc coating that significantly enhances its corrosion resistance by preventing moisture and oxygen from reaching the underlying metal. Non-galvanized iron lacks this coating, making it more susceptible to rust and degradation when exposed to humid or wet environments. The zinc layer in galvanized iron acts as a sacrificial anode, providing longer-lasting durability in outdoor or industrial applications compared to non-galvanized iron.

Longevity and Durability Comparison

Galvanized iron features a protective zinc coating that significantly enhances its resistance to rust and corrosion, extending its longevity compared to non-galvanized iron. Non-galvanized iron, lacking this protective layer, is more susceptible to oxidation and environmental damage, resulting in a shorter lifespan. The durability of galvanized iron makes it ideal for outdoor and industrial applications where exposure to moisture and harsh conditions is common.

Common Applications for Each Type of Iron

Galvanized iron is commonly used in outdoor applications such as roofing, fencing, and automotive parts due to its corrosion resistance from the zinc coating. Non-galvanized iron is typically found in indoor or structural applications like construction frameworks, machinery components, and furniture where exposure to moisture is limited. Selecting between galvanized and non-galvanized iron depends on environmental conditions and the need for rust protection in specific projects.

Cost Factors: Galvanized vs Non-Galvanized Iron

Galvanized iron typically incurs higher initial costs due to the zinc coating process that enhances corrosion resistance and extends lifespan. Non-galvanized iron has lower upfront expenses but may lead to increased maintenance and replacement costs over time because it lacks protection against rust. Considering total cost of ownership, galvanized iron often proves more economical in environments prone to moisture and corrosion.

Environmental Impact and Sustainability

Galvanized iron features a protective zinc coating that enhances corrosion resistance, reducing the frequency of replacements and minimizing raw material consumption over time. Non-galvanized iron, lacking this layer, is prone to rust, leading to increased resource use and waste due to shorter lifespan and more frequent maintenance. Sustainable construction favors galvanized iron for its durability and reduced environmental footprint through extended product life and lower material demand.

Choosing the Right Iron Material for Your Project

Galvanized iron offers superior corrosion resistance due to its protective zinc coating, making it ideal for outdoor or moisture-exposed projects. Non-galvanized iron, while more cost-effective, is prone to rust and better suited for indoor applications where exposure to elements is minimal. Selecting the right iron depends on environmental factors, budget constraints, and the desired longevity of the material in your specific project.

Galvanized Iron vs Non-Galvanized Iron Infographic

materialdif.com

materialdif.com