Corrugated iron features a distinctive wavy pattern that enhances its strength and durability, making it ideal for roofing and siding in construction. Flat iron, on the other hand, has a smooth, even surface favored for structural frameworks and decorative elements due to its uniform appearance. Both materials offer versatility, but corrugated iron excels in weather resistance while flat iron provides ease of fabrication and aesthetic appeal.

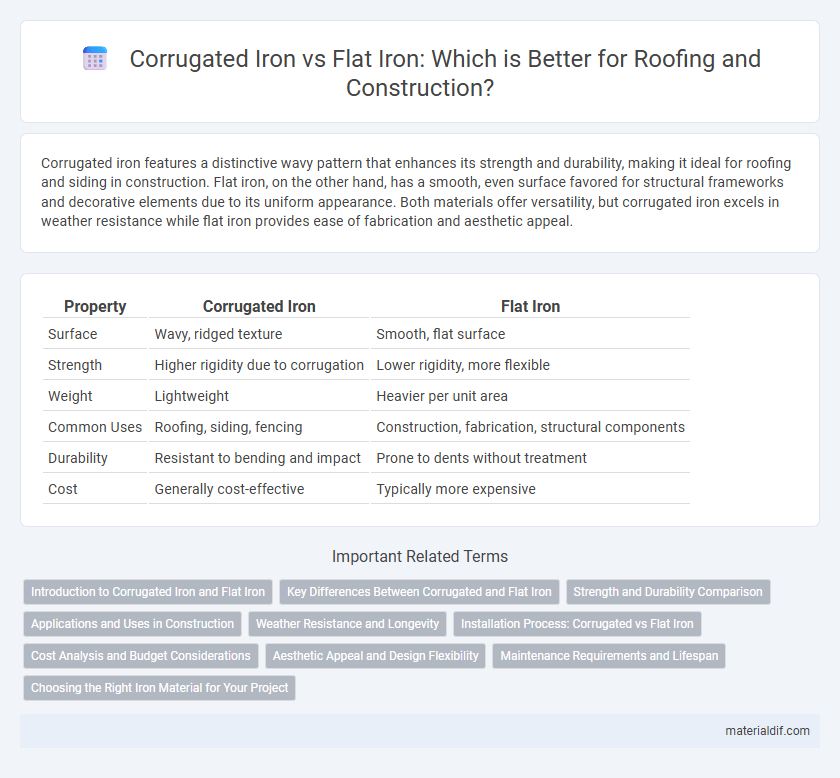

Table of Comparison

| Property | Corrugated Iron | Flat Iron |

|---|---|---|

| Surface | Wavy, ridged texture | Smooth, flat surface |

| Strength | Higher rigidity due to corrugation | Lower rigidity, more flexible |

| Weight | Lightweight | Heavier per unit area |

| Common Uses | Roofing, siding, fencing | Construction, fabrication, structural components |

| Durability | Resistant to bending and impact | Prone to dents without treatment |

| Cost | Generally cost-effective | Typically more expensive |

Introduction to Corrugated Iron and Flat Iron

Corrugated iron consists of sheets of iron or steel that have been rolled into a series of parallel ridges and grooves, significantly enhancing its strength and durability for roofing and siding applications. Flat iron refers to plain, smooth iron sheets without any corrugation, often used in construction where a flat, even surface is required. The corrugation process increases load-bearing capacity and water runoff efficiency, making corrugated iron ideal for outdoor structures, while flat iron serves more diverse uses due to its uniform profile.

Key Differences Between Corrugated and Flat Iron

Corrugated iron features a series of ridges and grooves that enhance its structural strength and durability, making it ideal for roofing and siding applications where weather resistance is crucial. Flat iron, in contrast, provides a smooth, uniform surface better suited for fabrication, decorative purposes, and construction requiring a sleek aesthetic. The key differences lie in their surface texture, mechanical properties, and typical use cases, with corrugated iron offering superior rigidity and flat iron delivering greater versatility in finishing.

Strength and Durability Comparison

Corrugated iron exhibits superior strength and durability compared to flat iron due to its wavy structure, which enhances load-bearing capacity and resistance to bending under pressure. The corrugations distribute stress more evenly across surfaces, preventing deformation and increasing lifespan in roofing and construction applications. Flat iron, being a smooth and flat sheet, lacks this inherent structural reinforcement, making it less effective in withstanding heavy loads and harsh environmental conditions.

Applications and Uses in Construction

Corrugated iron is widely used in roofing and siding for industrial, agricultural, and residential buildings due to its enhanced strength, durability, and ability to withstand harsh weather conditions. Flat iron is prevalent in structural applications such as beams, columns, and frameworks where uniform strength and a smooth surface are critical. Corrugated iron's ridged design increases load-bearing capacity, making it ideal for lightweight roofing structures, while flat iron provides the versatility required for custom metalwork and load-bearing components in construction projects.

Weather Resistance and Longevity

Corrugated iron offers superior weather resistance due to its ridged design, which enhances water runoff and reduces the risk of rust and corrosion compared to flat iron. Flat iron has a smoother surface that can accumulate water and debris, leading to quicker deterioration under harsh weather conditions. Longevity of corrugated iron typically exceeds flat iron, making it a preferred choice for roofing and outdoor applications where durability is essential.

Installation Process: Corrugated vs Flat Iron

Corrugated iron sheets feature a wavy pattern that allows for easy overlapping and faster installation, making them ideal for roofing with enhanced water runoff efficiency. Flat iron panels require precise alignment and fastening due to their smooth surface, resulting in a more time-consuming installation process often used for siding or decorative applications. The choice between corrugated and flat iron impacts labor cost and project duration, with corrugated iron generally preferred where quick, durable installation is desired.

Cost Analysis and Budget Considerations

Corrugated iron offers a cost-effective roofing solution, with prices typically 15-30% lower than flat iron due to simpler manufacturing and reduced material use. Flat iron provides a sleek appearance but often incurs higher expenses in both materials and installation, impacting overall budget allocation. When considering cost analysis, project budgets can benefit from corrugated iron's durability and affordability, especially in large-scale applications.

Aesthetic Appeal and Design Flexibility

Corrugated iron offers distinct aesthetic appeal with its ridged texture, creating dynamic shadows and a rustic, industrial look favored in modern architectural designs. Flat iron provides a smooth, sleek surface that enhances minimalist and contemporary structures, allowing for versatile finishing options such as painting and coating. Design flexibility in corrugated iron supports structural strength and water runoff, while flat iron excels in seamless appearances and easy customization for intricate patterns.

Maintenance Requirements and Lifespan

Corrugated iron requires less frequent maintenance due to its design, which facilitates water runoff and reduces rust buildup, extending its lifespan up to 40 years with proper care. Flat iron tends to accumulate water and debris, increasing the need for regular inspections and anti-corrosion treatments to prevent deterioration, typically lasting around 20-25 years. Choosing corrugated iron often results in lower maintenance costs and a longer service life compared to flat iron in similar environmental conditions.

Choosing the Right Iron Material for Your Project

Corrugated iron offers enhanced strength and durability due to its ridged surface, making it ideal for roofing and structural applications where weather resistance and load-bearing capacity are critical. Flat iron provides a smooth, uniform appearance suited for decorative or framing purposes requiring easier fabrication and welding. Selecting between corrugated and flat iron depends on the specific structural demands, environmental exposure, and aesthetic requirements of your project.

Corrugated Iron vs Flat Iron Infographic

materialdif.com

materialdif.com