Iron smelting involves extracting iron from its ore by heating and melting, producing raw iron often called pig iron containing impurities. Iron refining follows smelting and aims to remove impurities and adjust carbon content, resulting in purer iron suitable for specific industrial uses. The refining process enhances the strength, ductility, and corrosion resistance of the final iron product.

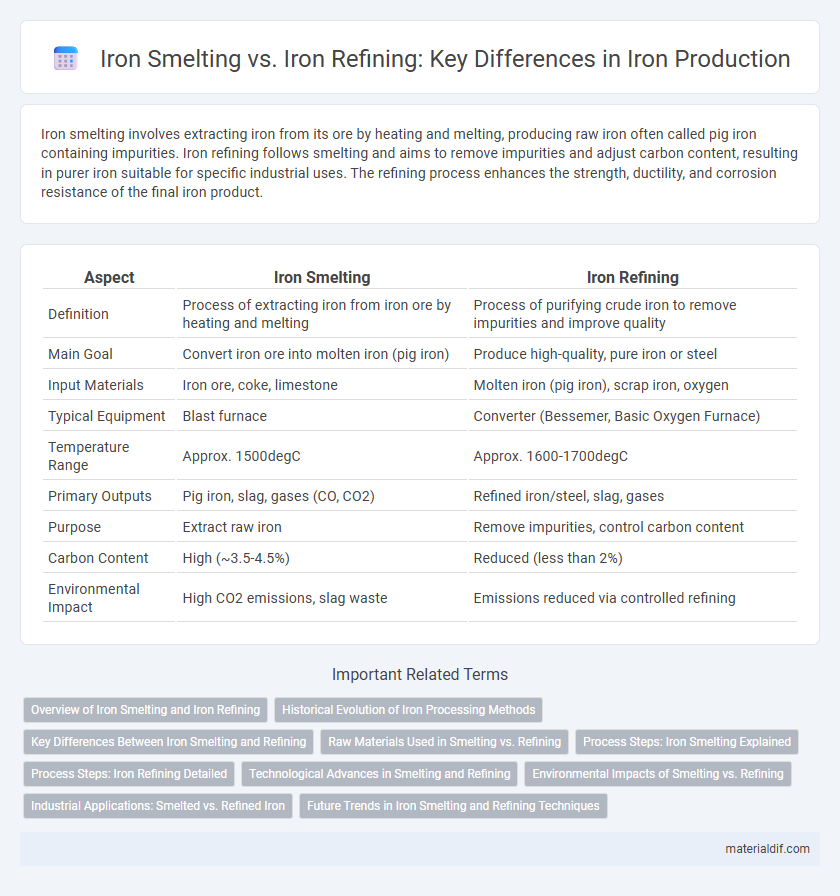

Table of Comparison

| Aspect | Iron Smelting | Iron Refining |

|---|---|---|

| Definition | Process of extracting iron from iron ore by heating and melting | Process of purifying crude iron to remove impurities and improve quality |

| Main Goal | Convert iron ore into molten iron (pig iron) | Produce high-quality, pure iron or steel |

| Input Materials | Iron ore, coke, limestone | Molten iron (pig iron), scrap iron, oxygen |

| Typical Equipment | Blast furnace | Converter (Bessemer, Basic Oxygen Furnace) |

| Temperature Range | Approx. 1500degC | Approx. 1600-1700degC |

| Primary Outputs | Pig iron, slag, gases (CO, CO2) | Refined iron/steel, slag, gases |

| Purpose | Extract raw iron | Remove impurities, control carbon content |

| Carbon Content | High (~3.5-4.5%) | Reduced (less than 2%) |

| Environmental Impact | High CO2 emissions, slag waste | Emissions reduced via controlled refining |

Overview of Iron Smelting and Iron Refining

Iron smelting involves extracting pure iron from its ore by heating and melting, typically using a blast furnace where iron oxides are reduced by carbon. Iron refining follows smelting and focuses on removing impurities such as carbon, sulfur, and phosphorus to produce high-quality steel or wrought iron. Both processes are essential in the iron production chain, with smelting converting ore to raw iron and refining enhancing its usability and mechanical properties.

Historical Evolution of Iron Processing Methods

Iron smelting originated around 2000 BCE, marked by the extraction of iron from ore using high-temperature furnaces like bloomery and blast furnaces. Over centuries, iron refining evolved to improve purity and usability, transitioning from manual hammering to modern techniques such as puddling and electrolysis. These advancements in iron processing significantly shaped metallurgical practices, catalyzing the development of stronger, more durable iron alloys.

Key Differences Between Iron Smelting and Refining

Iron smelting involves extracting iron from its ore by heating and melting, producing molten iron and slag, while iron refining focuses on purifying the extracted iron to remove impurities and improve its quality. Smelting primarily uses blast furnaces to convert iron oxides into metallic iron, whereas refining employs processes like basic oxygen furnaces or electric arc furnaces to adjust carbon content and eliminate contaminants. The key difference lies in smelting being the initial extraction stage and refining being the subsequent purification phase essential for producing usable steel or wrought iron.

Raw Materials Used in Smelting vs. Refining

Iron smelting primarily uses iron ore, coke, and limestone as raw materials to extract molten iron from its ore through high-temperature reduction. Iron refining involves raw materials such as scrap iron, pig iron, and gases like oxygen to purify and adjust the composition of the molten iron into steel. The raw materials in smelting are mainly mineral-based, while refining relies more on recycled metals and controlled atmospheric gases.

Process Steps: Iron Smelting Explained

Iron smelting involves extracting iron from its ore through a chemical process that heats the ore at high temperatures in a blast furnace, reducing iron oxides to molten iron. The main steps include ore preparation, coke production, the smelting reaction, and tapping the molten iron for further use. This process contrasts with iron refining, which primarily purifies and alters the composition of the raw iron to produce steel or other alloys.

Process Steps: Iron Refining Detailed

Iron refining involves several detailed steps following iron smelting, starting with the removal of impurities such as carbon, silicon, and sulfur through oxidation in a converter or furnace. The process includes decarburization where oxygen is blown into molten iron to reduce carbon content, producing steel or purer forms of iron. Subsequent steps may involve alloying, deoxidation, and secondary refining to achieve desired chemical composition and mechanical properties.

Technological Advances in Smelting and Refining

Technological advances in iron smelting, such as the introduction of blast furnaces and coke-based fuel, have significantly increased efficiency and output by enabling higher temperatures and better control of the reduction process. Innovations in iron refining, including the Bessemer process and basic oxygen steelmaking, have improved the removal of impurities and allowed for mass production of purer steel. These advancements collectively transformed the iron industry by reducing costs, enhancing material quality, and supporting large-scale industrial development.

Environmental Impacts of Smelting vs. Refining

Iron smelting releases significant amounts of carbon dioxide and sulfur dioxide due to the combustion of coke and other fossil fuels, contributing heavily to air pollution and greenhouse gas emissions. In contrast, iron refining typically generates fewer direct emissions, focusing on removing impurities through chemical processes, which results in lower overall environmental impact. However, refining consumes substantial energy, often sourced from electricity and gas, potentially causing indirect pollution depending on the energy mix.

Industrial Applications: Smelted vs. Refined Iron

Industrial applications differentiate iron smelting and refining by their output quality and utility; smelted iron, often containing impurities, is primarily used in construction and manufacturing where structural strength is essential. Refined iron, produced through processes like electrolysis or chemical reduction, exhibits higher purity and is critical for applications requiring corrosion resistance and precise alloy composition, such as automotive parts and aerospace components. The choice between smelted and refined iron directly impacts durability, performance, and cost-efficiency in sectors like infrastructure, transportation, and heavy machinery.

Future Trends in Iron Smelting and Refining Techniques

Future trends in iron smelting emphasize the integration of hydrogen-based reduction methods to lower carbon emissions and improve energy efficiency. Advancements in refining techniques focus on automation and real-time monitoring to enhance purity levels and reduce impurities in steel production. Industry investments in sustainable technologies signal a shift toward eco-friendly and cost-effective iron processing solutions.

Iron Smelting vs Iron Refining Infographic

materialdif.com

materialdif.com