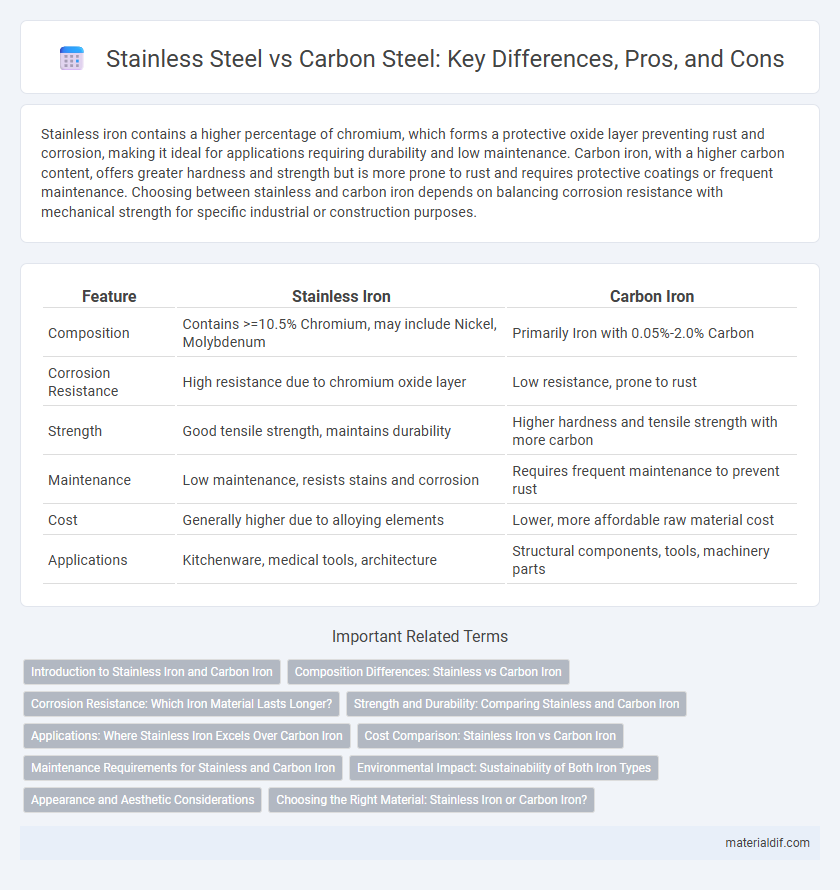

Stainless iron contains a higher percentage of chromium, which forms a protective oxide layer preventing rust and corrosion, making it ideal for applications requiring durability and low maintenance. Carbon iron, with a higher carbon content, offers greater hardness and strength but is more prone to rust and requires protective coatings or frequent maintenance. Choosing between stainless and carbon iron depends on balancing corrosion resistance with mechanical strength for specific industrial or construction purposes.

Table of Comparison

| Feature | Stainless Iron | Carbon Iron |

|---|---|---|

| Composition | Contains >=10.5% Chromium, may include Nickel, Molybdenum | Primarily Iron with 0.05%-2.0% Carbon |

| Corrosion Resistance | High resistance due to chromium oxide layer | Low resistance, prone to rust |

| Strength | Good tensile strength, maintains durability | Higher hardness and tensile strength with more carbon |

| Maintenance | Low maintenance, resists stains and corrosion | Requires frequent maintenance to prevent rust |

| Cost | Generally higher due to alloying elements | Lower, more affordable raw material cost |

| Applications | Kitchenware, medical tools, architecture | Structural components, tools, machinery parts |

Introduction to Stainless Iron and Carbon Iron

Stainless iron, primarily an alloy containing at least 10.5% chromium, offers superior corrosion resistance compared to carbon iron, making it ideal for applications requiring durability against oxidation. Carbon iron, containing varying levels of carbon up to about 2%, exhibits higher hardness and strength but is more prone to rust and corrosion. Understanding the composition differences between stainless and carbon iron is crucial for selecting the right material for construction, manufacturing, and tooling purposes.

Composition Differences: Stainless vs Carbon Iron

Stainless iron contains a minimum of 10.5% chromium, which forms a chromium oxide layer enhancing corrosion resistance, whereas carbon iron primarily consists of iron with a higher carbon content ranging from 0.05% to 2.0%, increasing its hardness and strength but reducing corrosion resistance. Stainless iron typically includes nickel and molybdenum, which improve durability and resistance to oxidation, while carbon iron may include small amounts of manganese and silicon for strength and hardness adjustments. The presence of chromium in stainless iron fundamentally distinguishes its chemical composition and mechanical properties from carbon iron, making it more suitable for environments requiring high corrosion resistance.

Corrosion Resistance: Which Iron Material Lasts Longer?

Stainless iron, primarily composed of iron alloyed with chromium and sometimes nickel, offers superior corrosion resistance by forming a passive oxide layer that protects against rust and environmental damage. Carbon iron, containing higher carbon content but lacking significant chromium, is more prone to oxidation and rust when exposed to moisture and air. Due to this protective oxide film, stainless iron generally lasts significantly longer than carbon iron in environments where corrosion is a concern.

Strength and Durability: Comparing Stainless and Carbon Iron

Stainless iron offers superior corrosion resistance and maintains strength under harsh environmental conditions due to its chromium content, making it highly durable for long-term applications. Carbon iron, while generally stronger and harder because of its higher carbon content, is more prone to rust and requires protective coatings in corrosive environments. Choosing between stainless and carbon iron depends on balancing the need for strength with resistance to wear and oxidation.

Applications: Where Stainless Iron Excels Over Carbon Iron

Stainless iron excels in applications requiring corrosion resistance such as kitchen appliances, medical instruments, and construction in humid environments due to its chromium content forming a passive oxide layer. It is preferred in food processing equipment and chemical industries because it resists staining, rust, and chemical degradation better than carbon iron. Carbon iron is favored for structural applications where strength and machinability are prioritized, but it lacks the durability needed in corrosive conditions where stainless iron thrives.

Cost Comparison: Stainless Iron vs Carbon Iron

Stainless iron typically costs 20% to 30% more than carbon iron due to the added alloying elements like chromium and nickel that enhance corrosion resistance. Carbon iron, being composed mainly of iron and carbon, is cheaper but less durable in harsh environments. Cost considerations often drive the choice between these materials depending on the application's exposure to moisture and chemicals.

Maintenance Requirements for Stainless and Carbon Iron

Stainless iron requires minimal maintenance due to its corrosion-resistant chromium content, which prevents rust and reduces the need for frequent cleaning or protective coatings. Carbon iron, prone to rust and oxidation, demands regular maintenance such as oiling, painting, or coating to protect its surface and prevent degradation. Proper upkeep of carbon iron is essential to extend its lifespan, whereas stainless iron offers greater durability with less maintenance effort.

Environmental Impact: Sustainability of Both Iron Types

Stainless iron, primarily composed of iron alloyed with chromium and nickel, offers superior corrosion resistance, reducing the need for frequent replacement and minimizing waste. Carbon iron, or carbon steel, requires less energy-intensive production but tends to rust faster, leading to higher maintenance and shorter lifecycle impacts. Sustainable practices prioritize recycling both iron types, though stainless iron's durability often results in a lower overall environmental footprint despite its initially higher production emissions.

Appearance and Aesthetic Considerations

Stainless iron features a sleek, shiny surface due to its chromium content, which enhances corrosion resistance and maintains a polished, modern appearance over time. Carbon iron often has a matte or rough texture that can develop rust and discoloration, affecting its visual appeal and requiring regular maintenance. The aesthetic durability of stainless iron makes it a preferred choice for architectural and decorative applications where long-lasting visual quality is essential.

Choosing the Right Material: Stainless Iron or Carbon Iron?

Choosing between stainless iron and carbon iron depends on the application's requirements for corrosion resistance and strength. Stainless iron, alloyed with chromium, offers superior rust protection and durability in harsh environments, while carbon iron provides higher tensile strength and is more cost-effective for structural uses. Evaluating environmental exposure and mechanical demands ensures optimal material selection for longevity and performance.

Stainless Iron vs Carbon Iron Infographic

materialdif.com

materialdif.com