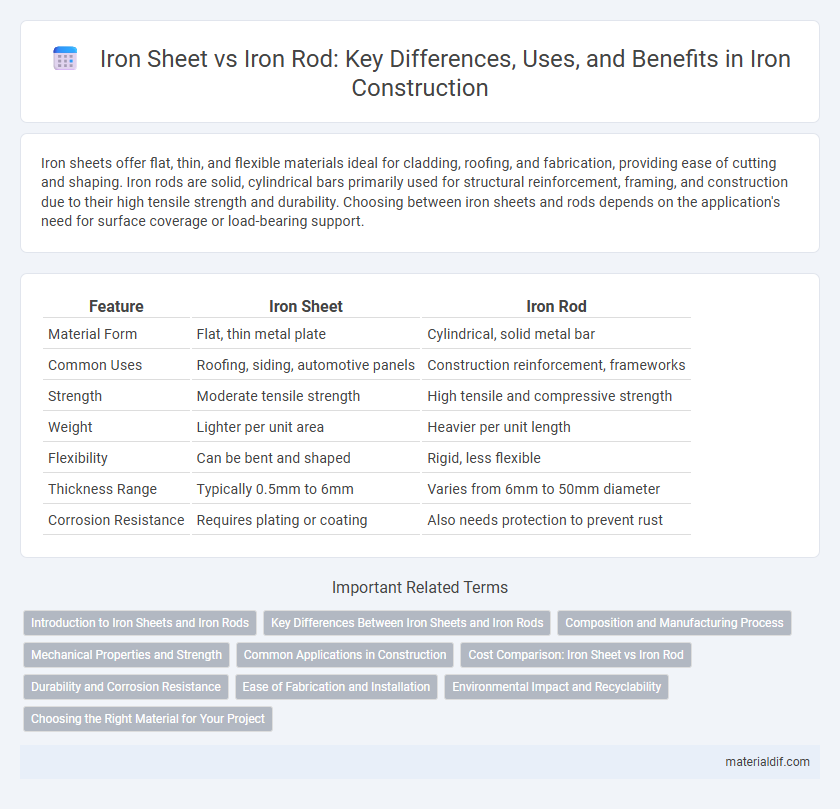

Iron sheets offer flat, thin, and flexible materials ideal for cladding, roofing, and fabrication, providing ease of cutting and shaping. Iron rods are solid, cylindrical bars primarily used for structural reinforcement, framing, and construction due to their high tensile strength and durability. Choosing between iron sheets and rods depends on the application's need for surface coverage or load-bearing support.

Table of Comparison

| Feature | Iron Sheet | Iron Rod |

|---|---|---|

| Material Form | Flat, thin metal plate | Cylindrical, solid metal bar |

| Common Uses | Roofing, siding, automotive panels | Construction reinforcement, frameworks |

| Strength | Moderate tensile strength | High tensile and compressive strength |

| Weight | Lighter per unit area | Heavier per unit length |

| Flexibility | Can be bent and shaped | Rigid, less flexible |

| Thickness Range | Typically 0.5mm to 6mm | Varies from 6mm to 50mm diameter |

| Corrosion Resistance | Requires plating or coating | Also needs protection to prevent rust |

Introduction to Iron Sheets and Iron Rods

Iron sheets are flat, thin pieces of iron commonly used in construction, roofing, and manufacturing due to their durability and ease of fabrication. Iron rods, characterized by their cylindrical shape, are primarily utilized as reinforcement in concrete structures, providing tensile strength and stability. Both materials play critical roles in structural applications, with iron sheets offering surface coverage and rods ensuring internal support.

Key Differences Between Iron Sheets and Iron Rods

Iron sheets are flat, thin metal plates primarily used in construction for roofing, cladding, and manufacturing durable metal containers, whereas iron rods are solid cylindrical bars typically employed as reinforcement in concrete structures and frameworks. The mechanical properties differ significantly, with iron sheets offering surface coverage and flexibility, while iron rods provide tensile strength and structural support. Understanding these functional and material differences is crucial for selecting the appropriate iron form in building and industrial applications.

Composition and Manufacturing Process

Iron sheets are typically made from low-carbon steel with a smooth, flat surface produced through rolling processes such as hot rolling or cold rolling to achieve uniform thickness and strength. Iron rods, usually composed of mild steel or medium-carbon steel, undergo hot rolling followed by quenching and tempering to enhance tensile strength and flexibility for construction use. The composition differences and distinct manufacturing techniques result in varied mechanical properties suited for specific structural applications.

Mechanical Properties and Strength

Iron sheets exhibit high tensile strength and flexibility, making them ideal for applications requiring surface coverage and resistance to bending forces. Iron rods possess superior compressive strength and rigidity, providing excellent support and load-bearing capacity in construction frameworks. Mechanical properties such as yield strength and ductility differ significantly, with rods generally offering higher structural integrity compared to sheets.

Common Applications in Construction

Iron sheets are widely used in roofing, cladding, and wall panels due to their lightweight, corrosion resistance, and ease of installation. Iron rods provide essential structural support in concrete reinforcement, framework construction, and load-bearing elements because of their high tensile strength and durability. Both materials significantly contribute to the stability and longevity of buildings but serve distinct functional roles in construction projects.

Cost Comparison: Iron Sheet vs Iron Rod

Iron sheets generally cost less per unit area compared to iron rods, making them more economical for large surface coverage projects like roofing or cladding. Iron rods, priced based on diameter and length, tend to be more expensive due to their structural applications in construction and reinforcement. Cost variation also depends on factors such as market demand, manufacturing processes, and material grades for both iron sheets and rods.

Durability and Corrosion Resistance

Iron sheets exhibit higher surface durability and better resistance to wear due to their flat, uniform structure, making them ideal for roofing and cladding applications. Iron rods, with their solid cylindrical shape, offer superior tensile strength and structural support but are more prone to rust and corrosion without protective coatings. Both materials benefit from galvanization or other anti-corrosive treatments to enhance longevity in harsh environments.

Ease of Fabrication and Installation

Iron sheets offer greater ease of fabrication and installation due to their flat, flexible surface that can be easily cut, bent, and shaped to various designs. Iron rods require more specialized tools and labor for cutting and welding, making the fabrication process more complex and time-consuming. The lightweight nature of iron sheets also simplifies transportation and installation compared to the bulkier, heavier iron rods.

Environmental Impact and Recyclability

Iron sheets have a lower environmental impact during production due to their thinner structure requiring less raw material and energy compared to iron rods, which are thicker and demand more intensive manufacturing processes. Both iron sheets and rods are highly recyclable, with recycling rates exceeding 90% globally, significantly reducing their carbon footprint by minimizing the need for virgin ore extraction. The recyclability of iron components plays a crucial role in sustainable construction and manufacturing by conserving natural resources and lowering greenhouse gas emissions.

Choosing the Right Material for Your Project

Iron sheets offer a flat, lightweight, and versatile option ideal for roofing, cladding, and fabrication projects requiring flexibility and surface coverage. Iron rods provide superior tensile strength and structural support, making them essential for construction frameworks, reinforcements, and load-bearing applications. Selecting the right material depends on the project's functional requirements, with iron sheets favored for surface applications and iron rods chosen for durability and strength.

Iron Sheet vs Iron Rod Infographic

materialdif.com

materialdif.com