Hot rolled iron is processed at high temperatures, which makes it easier to shape and form, resulting in a rougher surface texture ideal for construction and welding applications. Cold rolled iron undergoes further processing at room temperature, producing a smoother finish with tighter tolerances, enhancing strength and surface precision for manufacturing and automotive uses. Choosing between hot rolled and cold rolled iron depends on the specific requirements for strength, finish quality, and dimensional accuracy in the intended project.

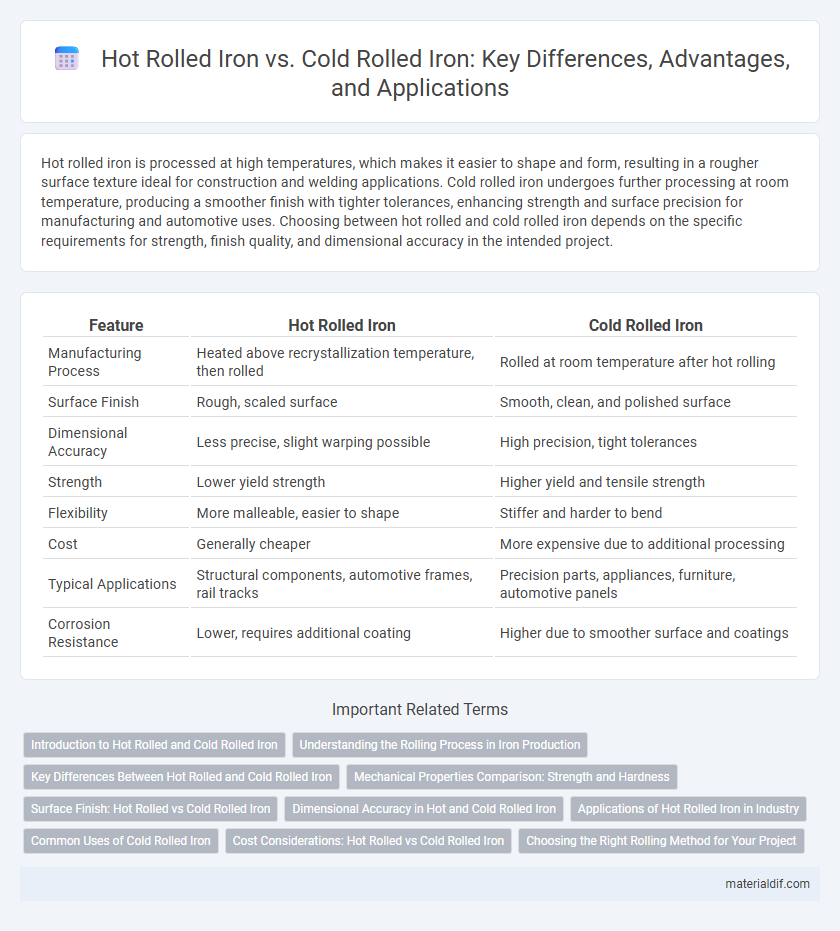

Table of Comparison

| Feature | Hot Rolled Iron | Cold Rolled Iron |

|---|---|---|

| Manufacturing Process | Heated above recrystallization temperature, then rolled | Rolled at room temperature after hot rolling |

| Surface Finish | Rough, scaled surface | Smooth, clean, and polished surface |

| Dimensional Accuracy | Less precise, slight warping possible | High precision, tight tolerances |

| Strength | Lower yield strength | Higher yield and tensile strength |

| Flexibility | More malleable, easier to shape | Stiffer and harder to bend |

| Cost | Generally cheaper | More expensive due to additional processing |

| Typical Applications | Structural components, automotive frames, rail tracks | Precision parts, appliances, furniture, automotive panels |

| Corrosion Resistance | Lower, requires additional coating | Higher due to smoother surface and coatings |

Introduction to Hot Rolled and Cold Rolled Iron

Hot rolled iron is produced by rolling heated steel above its recrystallization temperature, resulting in a rough surface and looser tolerances ideal for structural applications. Cold rolled iron undergoes further processing at room temperature, enhancing surface finish, strength, and dimensional precision for use in automotive and appliance manufacturing. The distinction lies in thermomechanical processing, impacting mechanical properties and surface quality tailored to specific industrial needs.

Understanding the Rolling Process in Iron Production

Hot rolled iron undergoes processing at high temperatures above its recrystallization point, allowing easier shaping and resulting in a rough surface texture with less precise dimensions. Cold rolled iron is processed below its recrystallization temperature, enhancing its strength and surface finish through additional deformation and annealing steps that improve dimensional accuracy. The temperature difference in the rolling processes significantly impacts the mechanical properties, surface quality, and application suitability of iron products.

Key Differences Between Hot Rolled and Cold Rolled Iron

Hot rolled iron undergoes processing at high temperatures above its recrystallization point, resulting in a rough surface and looser tolerances, ideal for structural applications where precision is less critical. Cold rolled iron is processed at room temperature, which enhances its surface finish, increases strength through strain hardening, and produces tighter dimensional tolerances suitable for precision engineering and automotive parts. The key differences lie in temperature of processing, surface texture, mechanical properties, and typical applications, influencing choice based on strength requirements and finish quality.

Mechanical Properties Comparison: Strength and Hardness

Hot rolled iron exhibits lower tensile strength and hardness compared to cold rolled iron due to its rougher surface and less precise dimensional tolerances. Cold rolled iron undergoes additional processing, which refines its grain structure, enhancing mechanical properties such as increased yield strength and hardness. The improved surface finish and rigidity of cold rolled iron make it preferable for applications requiring higher strength and wear resistance.

Surface Finish: Hot Rolled vs Cold Rolled Iron

Hot rolled iron features a rougher surface finish due to the metal cooling naturally after being rolled at high temperatures, resulting in scaled, less uniform textures ideal for structural applications. Cold rolled iron undergoes further processing at room temperature, producing a smoother, more polished surface with tighter tolerances suitable for precision engineering and decorative uses. The enhanced surface finish of cold rolled iron improves paint adhesion and corrosion resistance compared to hot rolled iron.

Dimensional Accuracy in Hot and Cold Rolled Iron

Hot rolled iron typically exhibits less dimensional accuracy due to its processing at high temperatures, causing the metal to slightly warp or expand. Cold rolled iron, processed at room temperature, offers superior dimensional precision and a smoother surface finish, making it ideal for applications requiring exact measurements. The enhanced dimensional control in cold rolled iron results from controlled deformation and tighter tolerances achieved during the cold rolling process.

Applications of Hot Rolled Iron in Industry

Hot rolled iron is extensively used in construction, manufacturing, and automotive industries due to its superior ductility and ease of welding. This material is ideal for structural components, railroad tracks, and pipelines where dimensional accuracy is less critical but strength and toughness are essential. Its applications also include heavy machinery parts and agricultural equipment, benefiting from the increased malleability and reduced cost compared to cold rolled iron.

Common Uses of Cold Rolled Iron

Cold rolled iron is commonly used in applications requiring precise dimensions and a smooth surface finish, such as automotive parts, home appliances, and furniture manufacturing. Its enhanced strength and improved surface quality make it ideal for interior components and decorative elements. The steel's consistent thickness and superior machinability support production processes where accuracy and aesthetics are critical.

Cost Considerations: Hot Rolled vs Cold Rolled Iron

Hot rolled iron generally costs less due to its simpler manufacturing process, which involves rolling the metal at high temperatures without additional finishing. Cold rolled iron undergoes extra processing steps like cooling and annealing, increasing production costs but resulting in a smoother surface and tighter tolerances. The choice between hot rolled and cold rolled iron depends on budget constraints and the specific requirements for surface finish and dimensional accuracy.

Choosing the Right Rolling Method for Your Project

Hot rolled iron features a rougher surface and greater malleability, making it ideal for structural components and welding projects where strength and durability are priorities. Cold rolled iron offers a smoother finish, tighter tolerances, and increased strength due to work hardening, which suits precision applications and finished products requiring enhanced surface quality. Selecting between hot rolled and cold rolled iron depends on the project's requirements for surface finish, dimensional accuracy, and mechanical properties.

Hot Rolled Iron vs Cold Rolled Iron Infographic

materialdif.com

materialdif.com