The iron core, primarily composed of solid and liquid iron, generates Earth's magnetic field through dynamic movements and convection currents. In contrast, the iron shell, or iron crust, forms the outer layer of iron-rich minerals that provide structural support and protect the core from external forces. Understanding the differences between the iron core and iron shell is essential for studying Earth's geodynamics and magnetic properties.

Table of Comparison

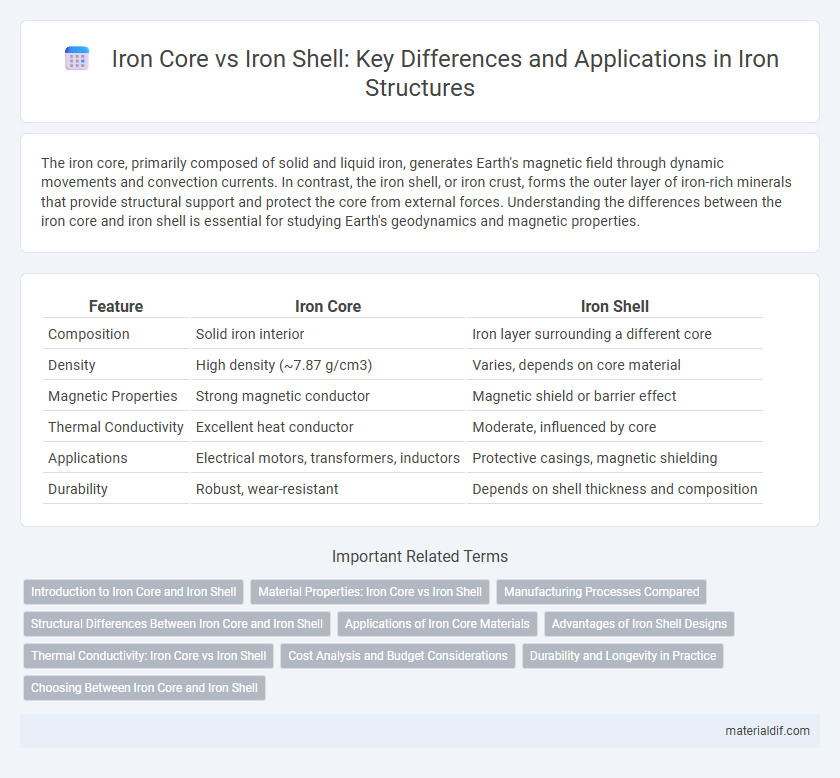

| Feature | Iron Core | Iron Shell |

|---|---|---|

| Composition | Solid iron interior | Iron layer surrounding a different core |

| Density | High density (~7.87 g/cm3) | Varies, depends on core material |

| Magnetic Properties | Strong magnetic conductor | Magnetic shield or barrier effect |

| Thermal Conductivity | Excellent heat conductor | Moderate, influenced by core |

| Applications | Electrical motors, transformers, inductors | Protective casings, magnetic shielding |

| Durability | Robust, wear-resistant | Depends on shell thickness and composition |

Introduction to Iron Core and Iron Shell

Iron core refers to the dense central part of an object, primarily composed of iron, often found in planetary bodies or magnetic devices, playing a crucial role in generating magnetic fields. Iron shell denotes the outer layer made predominantly of iron, providing structural support and protection to the core. Understanding the distinction between iron core and iron shell is essential in fields like geophysics and materials science for analyzing magnetic properties and mechanical strength.

Material Properties: Iron Core vs Iron Shell

Iron core exhibits higher magnetic permeability and thermal conductivity compared to an iron shell, making it essential for electromagnetic applications such as transformers and motors. The iron shell typically offers enhanced corrosion resistance and mechanical strength due to surface treatments or alloying elements. Differences in microstructure between the core and shell influence properties like hardness, ductility, and electrical resistivity, optimizing performance for specific industrial uses.

Manufacturing Processes Compared

Iron core manufacturing involves processes like forging, casting, and powder metallurgy to achieve dense, magnetic properties ideal for electrical applications. Iron shell production typically uses stamping, welding, or machining, emphasizing structural integrity and corrosion resistance for protective casings. Core manufacturing prioritizes magnetic permeability, whereas shell fabrication focuses on strength and durability requirements.

Structural Differences Between Iron Core and Iron Shell

The iron core consists of tightly packed iron atoms arranged in a crystalline lattice, offering high magnetic permeability and structural integrity essential for electromagnetic applications. In contrast, the iron shell typically refers to a protective or outer layer composed of iron or iron alloys that provide corrosion resistance and mechanical support without contributing significantly to magnetic properties. Structural differences between the iron core's dense atomic arrangement and the iron shell's layered, often alloyed composition influence their respective roles in machinery, electronics, and construction.

Applications of Iron Core Materials

Iron core materials are extensively used in electromagnetic applications such as transformers, inductors, and electric motors due to their high magnetic permeability and efficient energy transfer properties. These materials reduce core losses and improve performance in power generation, distribution, and electronic devices by enhancing magnetic flux conduction. Iron shells, in contrast, primarily serve as structural supports or protective enclosures and do not contribute significantly to magnetic functionality.

Advantages of Iron Shell Designs

Iron shell designs offer superior structural integrity and enhanced protection against corrosion compared to traditional iron core setups. The outer iron shell acts as a robust barrier, reducing wear and extending the lifespan of components in industrial applications. This design also improves thermal conductivity and magnetic performance, making it ideal for use in electromagnets and electrical transformers.

Thermal Conductivity: Iron Core vs Iron Shell

Iron core exhibits significantly higher thermal conductivity compared to the iron shell, facilitating efficient heat transfer essential in applications like electrical transformers and induction heating. The crystalline structure and purity of the iron core enhance thermal dissipation, whereas the iron shell's composition and possible alloying elements can reduce its thermal conductivity. Understanding these differences aids in optimizing thermal management in industrial and engineering assemblies.

Cost Analysis and Budget Considerations

Iron core materials generally demand higher upfront investment due to complex manufacturing processes and quality requirements, impacting overall project budgets significantly. Iron shell options provide a cost-effective alternative with lower production expenses but may incur greater long-term maintenance costs because of reduced durability. Budget considerations must balance initial expenditure against lifecycle costs to determine optimal material selection for structural or industrial applications.

Durability and Longevity in Practice

Iron cores exhibit superior durability due to their dense atomic structure, which offers enhanced resistance to wear, corrosion, and mechanical stress over time. Iron shells provide adequate protection but tend to be more susceptible to surface damage and environmental degradation, reducing their effective lifespan. Practical applications favor iron cores for long-term stability and sustained performance under harsh conditions.

Choosing Between Iron Core and Iron Shell

Choosing between an iron core and an iron shell depends on the specific application and desired magnetic properties. Iron cores, typically made from laminated or powdered iron, offer high magnetic permeability and low energy loss, making them ideal for transformers, inductors, and electromagnets. Iron shells provide structural protection and durability but have lower magnetic efficiency, making them more suitable for mechanical support rather than enhancing magnetic performance.

Iron Core vs Iron Shell Infographic

materialdif.com

materialdif.com