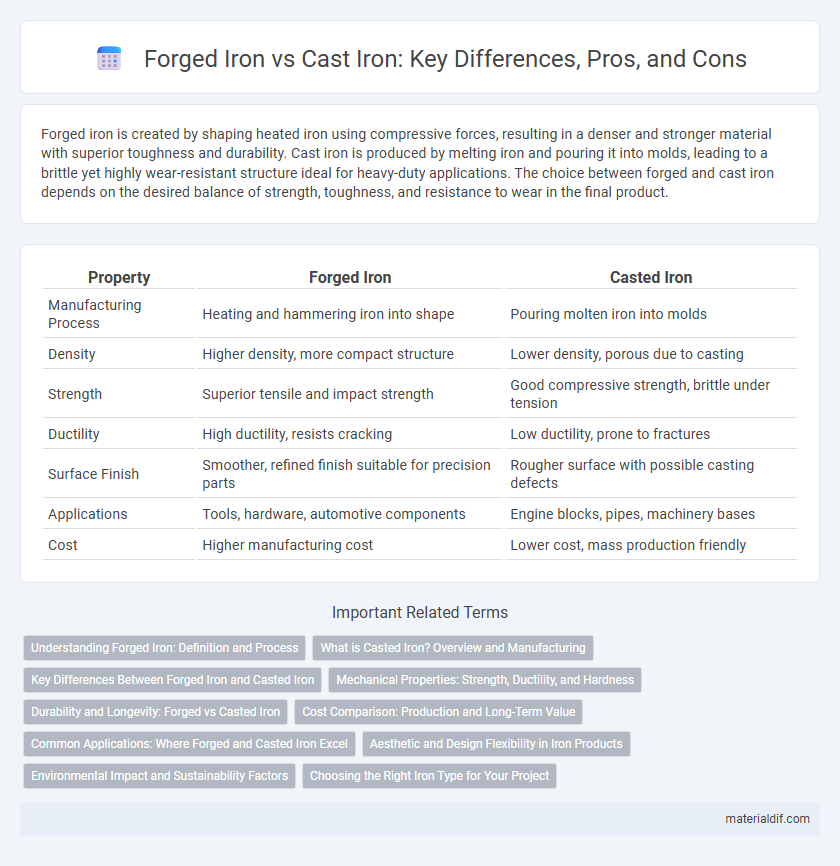

Forged iron is created by shaping heated iron using compressive forces, resulting in a denser and stronger material with superior toughness and durability. Cast iron is produced by melting iron and pouring it into molds, leading to a brittle yet highly wear-resistant structure ideal for heavy-duty applications. The choice between forged and cast iron depends on the desired balance of strength, toughness, and resistance to wear in the final product.

Table of Comparison

| Property | Forged Iron | Casted Iron |

|---|---|---|

| Manufacturing Process | Heating and hammering iron into shape | Pouring molten iron into molds |

| Density | Higher density, more compact structure | Lower density, porous due to casting |

| Strength | Superior tensile and impact strength | Good compressive strength, brittle under tension |

| Ductility | High ductility, resists cracking | Low ductility, prone to fractures |

| Surface Finish | Smoother, refined finish suitable for precision parts | Rougher surface with possible casting defects |

| Applications | Tools, hardware, automotive components | Engine blocks, pipes, machinery bases |

| Cost | Higher manufacturing cost | Lower cost, mass production friendly |

Understanding Forged Iron: Definition and Process

Forged iron is created through the process of heating iron to a malleable state and then shaping it by hammering or pressing, which enhances its strength and structural integrity. This method aligns the metal's grain structure, resulting in superior toughness and resistance to deformation compared to casted iron. Understanding forged iron involves recognizing its application in tools, machinery, and structural components where durability and fatigue resistance are critical.

What is Casted Iron? Overview and Manufacturing

Casted iron, also known as cast iron, is a group of iron-carbon alloys with a carbon content greater than 2%, characterized by its excellent fluidity, castability, and machinability. It is produced by melting iron and pouring it into molds where it solidifies, allowing for complex shapes and designs in manufacturing. Common types include gray cast iron, ductile cast iron, and white cast iron, each used in various applications due to their unique mechanical properties and corrosion resistance.

Key Differences Between Forged Iron and Casted Iron

Forged iron undergoes deformation under high pressure, resulting in a denser, stronger, and more durable material with enhanced tensile strength and impact resistance. Cast iron is produced by pouring molten iron into molds, creating a brittle but hard material with excellent compressive strength and good wear resistance. The key differences lie in the manufacturing processes, mechanical properties, and typical applications, with forged iron preferred for structural uses requiring toughness and cast iron favored for parts needing hardness and vibration damping.

Mechanical Properties: Strength, Ductility, and Hardness

Forged iron exhibits superior mechanical properties compared to cast iron, with higher strength and ductility due to its refined grain structure formed under controlled deformation. Cast iron, characterized by its brittle nature, has higher hardness but lower tensile strength and limited ductility because of its carbon-rich, coarse microstructure. These differences make forged iron ideal for applications requiring toughness and impact resistance, while cast iron suits wear-resistant components demanding hardness.

Durability and Longevity: Forged vs Casted Iron

Forged iron exhibits superior durability due to its grain structure, which is compressed and aligned during the forging process, resulting in enhanced strength and resistance to impact compared to cast iron. Cast iron, while strong under compression, tends to be more brittle and prone to cracking over time, limiting its longevity in applications subjected to dynamic stresses. The enhanced toughness of forged iron makes it a preferred choice for tools and components requiring long-lasting performance and resistance to wear.

Cost Comparison: Production and Long-Term Value

Forged iron typically involves higher production costs due to the labor-intensive process and specialized equipment required, while cast iron benefits from lower initial manufacturing expenses through mold casting techniques. Over the long term, forged iron offers superior durability and tensile strength, resulting in greater value for applications demanding structural integrity and resistance to fatigue. Cast iron, although cost-effective upfront, may incur higher maintenance or replacement costs due to brittleness and susceptibility to cracking under stress.

Common Applications: Where Forged and Casted Iron Excel

Forged iron demonstrates superior strength and toughness, making it ideal for high-stress applications such as automotive crankshafts, connecting rods, and heavy-duty machinery components. Cast iron excels in complex shapes and wear resistance, commonly used in engine blocks, pipes, and cookware due to its excellent castability and compressive strength. Both materials serve distinct industrial purposes where forged iron offers enhanced durability and cast iron provides cost-effective precision and thermal properties.

Aesthetic and Design Flexibility in Iron Products

Forged iron offers superior design flexibility with intricate details and custom shapes due to its malleability and manual shaping process. Cast iron, produced by pouring molten iron into molds, allows for complex, uniform patterns but is limited in fine detail and customization. Aesthetically, forged iron is preferred for unique, artisanal pieces, while cast iron suits mass-produced designs requiring consistent repetition.

Environmental Impact and Sustainability Factors

Forged iron generates less waste and requires lower energy consumption compared to casted iron, enhancing its sustainability profile. Casted iron production emits higher levels of CO2 due to melting processes and often involves more extensive raw material extraction. Choosing forged iron reduces environmental impact through improved recyclability and a smaller carbon footprint in manufacturing.

Choosing the Right Iron Type for Your Project

Forged iron offers superior strength and durability through a hammering process that aligns its grain structure, making it ideal for high-stress applications such as tools and structural components. Cast iron, produced by pouring molten iron into molds, provides excellent compressive strength and intricate shapes, suitable for cookware and decorative items. Selecting the right iron type depends on project requirements for toughness, precision, and weight tolerance.

Forged Iron vs Casted Iron Infographic

materialdif.com

materialdif.com