Blast furnace iron is produced by smelting iron ore with coke and limestone, resulting in higher carbon content and impurities that require further refining. Electric arc furnace (EAF) iron relies on recycling scrap steel, offering greater flexibility and lower energy consumption while producing a purer and more customizable steel alloy. Choosing between blast furnace and electric arc furnace iron depends on environmental goals, raw material availability, and desired steel quality.

Table of Comparison

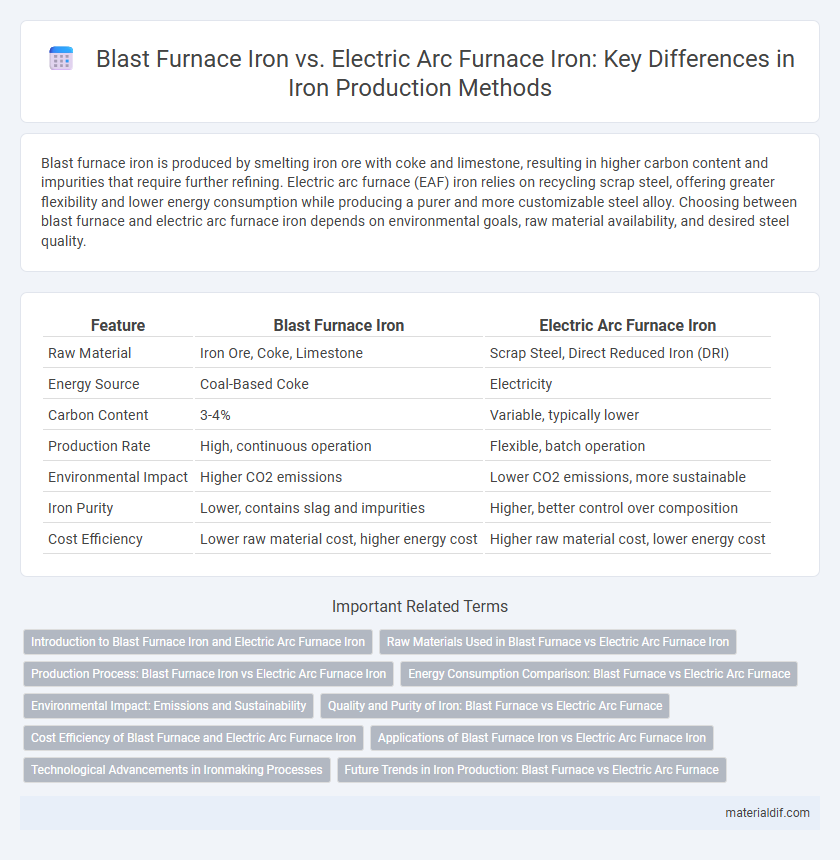

| Feature | Blast Furnace Iron | Electric Arc Furnace Iron |

|---|---|---|

| Raw Material | Iron Ore, Coke, Limestone | Scrap Steel, Direct Reduced Iron (DRI) |

| Energy Source | Coal-Based Coke | Electricity |

| Carbon Content | 3-4% | Variable, typically lower |

| Production Rate | High, continuous operation | Flexible, batch operation |

| Environmental Impact | Higher CO2 emissions | Lower CO2 emissions, more sustainable |

| Iron Purity | Lower, contains slag and impurities | Higher, better control over composition |

| Cost Efficiency | Lower raw material cost, higher energy cost | Higher raw material cost, lower energy cost |

Introduction to Blast Furnace Iron and Electric Arc Furnace Iron

Blast Furnace Iron is produced by reducing iron ore using coke and limestone at high temperatures in a blast furnace, resulting in molten pig iron with high carbon content. Electric Arc Furnace Iron is created by melting scrap steel or direct reduced iron using electric arcs, producing steel with lower impurities and greater recyclability. Both methods serve distinct roles in steel manufacturing, with blast furnace iron mainly used in traditional large-scale production and electric arc furnace iron favored for energy efficiency and environmental benefits.

Raw Materials Used in Blast Furnace vs Electric Arc Furnace Iron

Blast furnace iron primarily relies on iron ore, coke, and limestone as raw materials, where iron ore is reduced by carbon in coke at high temperatures. Electric arc furnace iron mainly utilizes scrap steel and direct reduced iron (DRI), utilizing electricity to melt these metallic feedstocks without the need for coke or iron ore. The raw material differences significantly affect energy consumption, emissions, and production flexibility between the two ironmaking processes.

Production Process: Blast Furnace Iron vs Electric Arc Furnace Iron

Blast furnace iron production involves the reduction of iron ore using coke and limestone at high temperatures, creating molten iron and slag through a chemical reaction in a blast furnace. Electric arc furnace iron production melts recycled scrap steel and direct reduced iron using electric arcs generated between carbon electrodes, allowing precise control over the temperature and composition. The blast furnace process is continuous and suited for large-scale ironmaking, while the electric arc furnace process offers flexibility and lower carbon emissions by utilizing recycled materials.

Energy Consumption Comparison: Blast Furnace vs Electric Arc Furnace

Blast furnace iron production consumes approximately 15-20 GJ of energy per ton, primarily derived from coal and coke, whereas electric arc furnace (EAF) iron uses around 4-6 GJ per ton, mainly sourced from electricity. The EAF process's reliance on recycled scrap metal significantly reduces overall energy demand compared to the blast furnace's reliance on iron ore reduction. This energy efficiency makes the electric arc furnace a more environmentally favorable choice in iron production, especially in regions with access to low-carbon electricity.

Environmental Impact: Emissions and Sustainability

Blast furnace iron production generates significant CO2 emissions due to the reliance on coke as a reducing agent, resulting in higher greenhouse gas output compared to electric arc furnace (EAF) iron. Electric arc furnace processes utilize scrap steel and electricity, which can be sourced from renewable energy, substantially lowering carbon footprints and promoting sustainability. Lifecycle assessments highlight EAF iron as a more environmentally friendly option, aligning with global efforts to reduce industrial emissions and achieve carbon neutrality.

Quality and Purity of Iron: Blast Furnace vs Electric Arc Furnace

Electric Arc Furnace (EAF) iron typically offers higher purity due to its ability to use scrap steel and precise control over input materials, resulting in fewer impurities such as sulfur and phosphorus compared to Blast Furnace (BF) iron. Blast Furnace iron relies on iron ore and coke, which often introduce higher levels of impurities and require further refining processes to achieve equivalent quality. The controlled environment of EAF enables production of steel with consistent chemical composition, making it preferable for applications demanding superior structural integrity and performance.

Cost Efficiency of Blast Furnace and Electric Arc Furnace Iron

Blast furnace iron production typically involves higher capital investment and longer startup times but benefits from lower raw material costs due to the use of abundant iron ore and coke, resulting in greater cost efficiency for large-scale, continuous operations. Electric arc furnace (EAF) iron relies on scrap metal and electricity, offering lower energy consumption and flexible production scales, making it more cost-effective in regions with low electricity prices and readily available scrap. Cost efficiency of blast furnace iron depends heavily on scale and raw material prices, while EAF iron excels in minimizing operational expenses in smaller, more adaptable manufacturing environments.

Applications of Blast Furnace Iron vs Electric Arc Furnace Iron

Blast furnace iron is predominantly used in large-scale steelmaking for construction, automotive, and heavy machinery industries due to its high carbon content and consistent quality. Electric arc furnace (EAF) iron is preferred for producing specialty steels and recycled steel products, as it allows flexible input materials and precise control over alloying elements. Applications of blast furnace iron favor mass production with high strength, while EAF iron suits customization and energy-efficient manufacturing processes.

Technological Advancements in Ironmaking Processes

Technological advancements in ironmaking have significantly differentiated blast furnace iron from electric arc furnace (EAF) iron, optimizing production efficiency and environmental impact. Blast furnace technology has evolved with improvements like top gas recycling and pulverized coal injection, enhancing fuel efficiency and reducing CO2 emissions, while EAF ironmaking benefits from innovations in scrap preheating and advanced arc control systems that boost energy efficiency and metal quality. These advancements support a shift towards more sustainable and flexible iron production methods tailored to varying raw material availability and industrial demands.

Future Trends in Iron Production: Blast Furnace vs Electric Arc Furnace

Future trends in iron production emphasize a shift towards Electric Arc Furnace (EAF) technology due to its lower carbon footprint and energy efficiency compared to traditional Blast Furnaces (BF). EAFs utilize recycled steel scrap, reducing dependency on iron ore and promoting circular economy practices, aligning with global sustainability goals. Innovations in renewable energy integration and direct reduced iron (DRI) feedstock further enhance EAF viability, positioning it as the preferred method for decarbonizing the iron and steel industry.

Blast Furnace Iron vs Electric Arc Furnace Iron Infographic

materialdif.com

materialdif.com