Spheroidal Graphite Iron, also known as ductile iron, features spherical graphite inclusions that enhance its ductility, impact resistance, and toughness, making it ideal for automotive and heavy machinery components. Compacted Graphite Iron contains worm-shaped graphite particles that provide higher strength, stiffness, and thermal conductivity compared to spheroidal graphite iron, offering improved performance in engine blocks and exhaust manifolds. The choice between these iron types depends on the required balance of mechanical properties and thermal management for specific industrial applications.

Table of Comparison

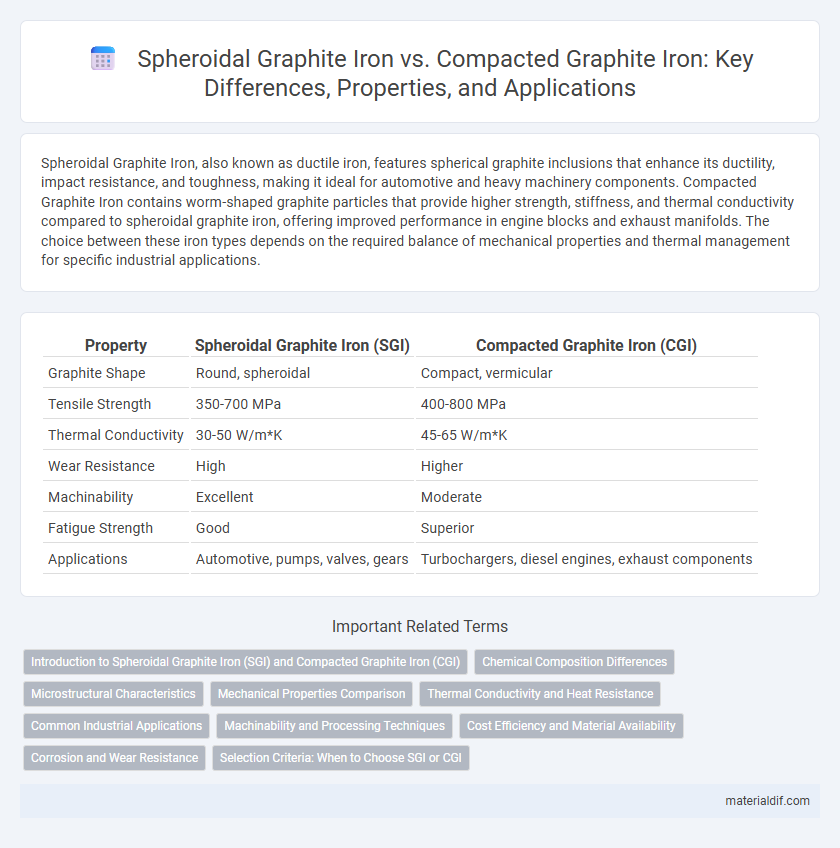

| Property | Spheroidal Graphite Iron (SGI) | Compacted Graphite Iron (CGI) |

|---|---|---|

| Graphite Shape | Round, spheroidal | Compact, vermicular |

| Tensile Strength | 350-700 MPa | 400-800 MPa |

| Thermal Conductivity | 30-50 W/m*K | 45-65 W/m*K |

| Wear Resistance | High | Higher |

| Machinability | Excellent | Moderate |

| Fatigue Strength | Good | Superior |

| Applications | Automotive, pumps, valves, gears | Turbochargers, diesel engines, exhaust components |

Introduction to Spheroidal Graphite Iron (SGI) and Compacted Graphite Iron (CGI)

Spheroidal Graphite Iron (SGI), also known as ductile iron, features spherical graphite nodules that enhance tensile strength, ductility, and impact resistance, making it ideal for automotive and heavy-duty applications. Compacted Graphite Iron (CGI) contains vermicular graphite particles that provide a unique combination of high strength and thermal conductivity, bridging the gap between grey cast iron and SGI. Both materials offer improved mechanical properties over traditional cast iron, with SGI excelling in toughness and CGI offering superior wear resistance and heat dissipation.

Chemical Composition Differences

Spheroidal Graphite Iron (SGI) contains higher magnesium and cerium levels to promote spherical graphite formation, enhancing ductility and toughness. Compacted Graphite Iron (CGI) typically has increased silicon and lower magnesium content, resulting in compacted, vermicular graphite that improves strength and thermal conductivity. The distinct variations in magnesium and silicon concentrations critically influence the microstructure and mechanical properties of both iron types.

Microstructural Characteristics

Spheroidal graphite iron features spherical graphite nodules that enhance ductility and toughness, while compacted graphite iron contains vermicular, or worm-like, graphite shapes that offer a balance between strength and thermal conductivity. The microstructure of spheroidal graphite iron typically exhibits a pearlitic or ferritic matrix, contributing to its excellent machinability and impact resistance. In contrast, compacted graphite iron's graphite morphology imparts higher stiffness and thermal fatigue resistance, making it ideal for automotive and heavy-duty engine components.

Mechanical Properties Comparison

Spheroidal Graphite Iron (SGI) offers superior ductility and impact resistance compared to Compacted Graphite Iron (CGI), which provides higher tensile strength and improved thermal conductivity. SGI's nodular graphite structure enhances fatigue resistance, making it ideal for automotive components requiring toughness, while CGI's vermicular graphite morphology delivers better wear resistance and stiffness suitable for heavy-duty engine parts. Mechanical testing reveals CGI typically exhibits tensile strengths up to 500 MPa and thermal conductivity around 40 W/m*K, whereas SGI shows tensile strengths of 350-450 MPa with lower thermal conductivity near 30 W/m*K.

Thermal Conductivity and Heat Resistance

Spheroidal Graphite Iron (SGI) exhibits lower thermal conductivity compared to Compacted Graphite Iron (CGI), due to its graphite morphology that reduces efficient heat transfer. CGI's unique worm-like graphite structure enhances heat resistance and thermal conductivity, making it suitable for high-temperature applications like engine components. The superior heat dissipation properties of CGI contribute to improved durability under thermal stress.

Common Industrial Applications

Spheroidal Graphite Iron (SGI), known for its excellent ductility and toughness, is widely used in automotive components like crankshafts, gears, and suspension parts. Compacted Graphite Iron (CGI) offers increased strength and thermal conductivity, making it ideal for engine blocks, cylinder heads, and brake components in heavy-duty vehicles. Both materials enhance performance and durability in industrial applications requiring high mechanical strength and fatigue resistance.

Machinability and Processing Techniques

Spheroidal Graphite Iron (SGI), also known as ductile iron, exhibits superior machinability due to its rounded graphite nodules that reduce stress concentration and tool wear, enabling faster and more efficient cutting operations. In contrast, Compacted Graphite Iron (CGI) contains vermicular graphite particles that enhance strength and thermal conductivity but present challenges in machining, requiring specialized tooling and slower processing speeds to manage brittleness and tool abrasion. Processing techniques for SGI typically involve conventional machining methods, while CGI demands optimized cutting parameters and advanced cooling methods to maintain tool life and part integrity.

Cost Efficiency and Material Availability

Spheroidal Graphite Iron (SGI), also known as Ductile Iron, offers superior cost efficiency due to its lower production costs and widespread material availability, making it ideal for large-scale manufacturing. Compact Graphite Iron (CGI) provides enhanced strength and thermal conductivity but incurs higher raw material and processing expenses, limiting its cost-effectiveness in budget-sensitive applications. The abundant global supply chain for SGI ensures consistent material access, whereas CGI's specialized production requirements result in more restricted availability and increased lead times.

Corrosion and Wear Resistance

Spheroidal Graphite Iron (SGI) exhibits superior corrosion resistance due to its rounded graphite structure, which minimizes stress concentration sites and enhances material integrity in aggressive environments. Compacted Graphite Iron (CGI) provides enhanced wear resistance owing to its unique vermicular graphite morphology, increasing hardness and load-bearing capacity under abrasive conditions. While both materials offer valuable properties, SGI is preferred for applications requiring higher corrosion resistance, whereas CGI excels in wear-critical components.

Selection Criteria: When to Choose SGI or CGI

Spheroidal Graphite Iron (SGI) is preferred for applications requiring excellent ductility, impact resistance, and fatigue strength, such as automotive components and pressure vessels. Compacted Graphite Iron (CGI) offers superior thermal conductivity, higher strength, and better wear resistance, making it ideal for engine blocks and exhaust manifolds exposed to high-temperature stress. Selection between SGI and CGI depends on factors like mechanical property requirements, thermal performance, and operating environment demands.

Spheroidal Graphite Iron vs Compacted Graphite Iron Infographic

materialdif.com

materialdif.com