Sheet iron refers to thin, flat pieces of iron typically less than 3mm thick, commonly used in automotive panels and roofing due to its malleability and ease of fabrication. Plate iron is significantly thicker, usually over 6mm, offering enhanced strength and durability ideal for heavy-duty applications such as structural support and industrial machinery. Both forms vary in thickness and application, making sheet iron suitable for lightweight tasks and plate iron essential for robust, load-bearing projects.

Table of Comparison

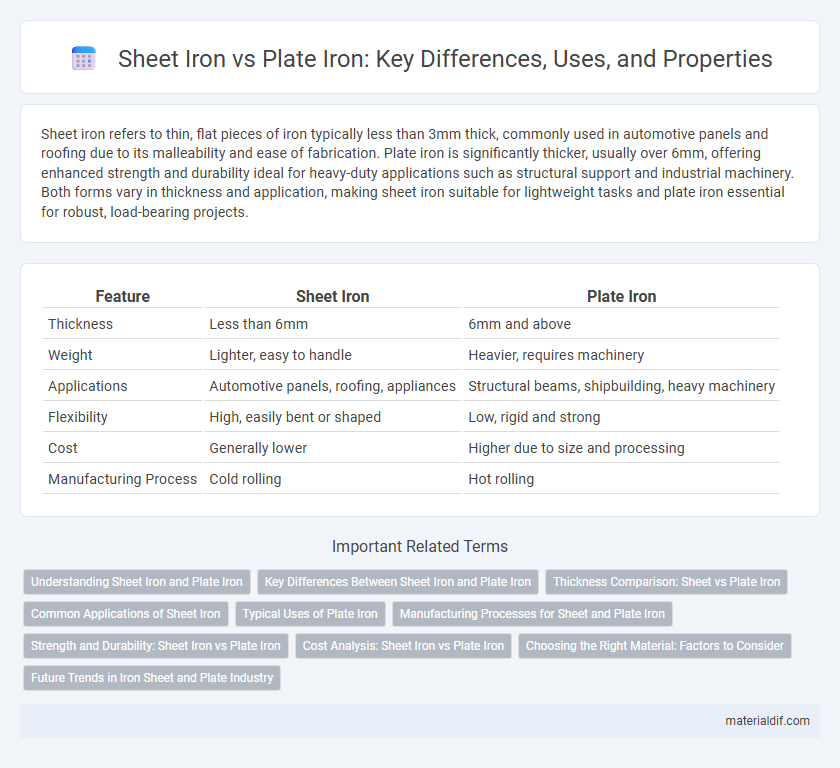

| Feature | Sheet Iron | Plate Iron |

|---|---|---|

| Thickness | Less than 6mm | 6mm and above |

| Weight | Lighter, easy to handle | Heavier, requires machinery |

| Applications | Automotive panels, roofing, appliances | Structural beams, shipbuilding, heavy machinery |

| Flexibility | High, easily bent or shaped | Low, rigid and strong |

| Cost | Generally lower | Higher due to size and processing |

| Manufacturing Process | Cold rolling | Hot rolling |

Understanding Sheet Iron and Plate Iron

Sheet iron typically refers to thin, flat pieces of iron that are less than 6mm thick and are commonly used in applications where flexibility and lightness are essential, such as automotive panels and roofing. Plate iron is thicker, generally exceeding 6mm, and offers greater strength and rigidity, making it suitable for heavy-duty construction, machinery bases, and structural components. Understanding the distinction between sheet iron and plate iron is crucial for selecting the right material based on load-bearing capacity, durability, and fabrication requirements.

Key Differences Between Sheet Iron and Plate Iron

Sheet iron typically measures less than 6 mm in thickness, offering greater flexibility and ease of fabrication for automotive and decorative applications. Plate iron, exceeding 6 mm in thickness, delivers superior strength and durability suitable for heavy structural uses like bridges and industrial machinery. The primary differences lie in their thickness, mechanical strength, and ideal utilization environments, impacting both manufacturing processes and end-use performance.

Thickness Comparison: Sheet vs Plate Iron

Sheet iron typically ranges in thickness from 0.5 mm to 6 mm, making it thinner and more flexible for applications requiring detailed shaping or bending. Plate iron starts at thicknesses above 6 mm, often extending beyond 25 mm, providing enhanced strength and durability suitable for heavy-duty construction and structural uses. The clear thickness distinction between sheet iron and plate iron influences their selection based on mechanical requirements and fabrication processes.

Common Applications of Sheet Iron

Sheet iron, characterized by its thin and flat form, is commonly used in automotive body panels, roofing, and HVAC ductwork due to its ease of shaping and welding. This material is also prevalent in manufacturing household appliances and decorative items, offering durability and corrosion resistance. In contrast to plate iron, sheet iron's thinner gauge makes it ideal for applications requiring flexibility and intricate metalwork.

Typical Uses of Plate Iron

Plate iron is commonly used in heavy-duty applications such as structural steel fabrication, shipbuilding, and industrial machinery due to its thickness and durability. It provides superior strength and resistance to impact, making it ideal for construction of bridges, pressure vessels, and storage tanks. Typical uses also include manufacturing of railway tracks, heavy equipment, and large-scale metalwork requiring robust material performance.

Manufacturing Processes for Sheet and Plate Iron

Sheet iron is produced through hot rolling or cold rolling processes that reduce the thickness of the iron to less than 6 millimeters, ensuring a smooth, uniform surface suited for applications requiring flexibility and precise dimensions. Plate iron, typically thicker than 6 millimeters, undergoes hot rolling where the iron slab is heated above recrystallization temperature and passed through rollers to achieve the desired thickness and mechanical strength, making it ideal for structural and heavy-duty uses. Both manufacturing methods involve controlled cooling and surface finishing techniques to enhance durability, but plate iron often requires additional heat treatment to improve toughness and reduce residual stresses.

Strength and Durability: Sheet Iron vs Plate Iron

Plate iron exhibits superior strength and durability compared to sheet iron due to its greater thickness and density, making it ideal for heavy-duty structural applications. Sheet iron, while lighter and more flexible, offers less resistance to impact and wear, suited for lighter, less demanding projects. The increased mass and compact grain structure in plate iron enhance its load-bearing capacity and longevity under stress.

Cost Analysis: Sheet Iron vs Plate Iron

Sheet iron typically costs less than plate iron due to its thinner gauge and ease of fabrication, making it ideal for lightweight applications. Plate iron, with its greater thickness and higher strength, commands a higher price reflecting its durability and suitability for heavy-duty projects. Evaluating the cost difference involves considering both initial material expenses and long-term performance requirements.

Choosing the Right Material: Factors to Consider

Sheet iron offers thinner gauges ideal for lightweight applications and easier shaping, while plate iron provides thicker, sturdier options suited for heavy-duty structural use. Consider factors such as load-bearing capacity, thickness requirements, and intended use environment when selecting between sheet and plate iron. Corrosion resistance and cost-effectiveness also play crucial roles in determining the optimal iron material for specific industrial or construction projects.

Future Trends in Iron Sheet and Plate Industry

The future trends in the iron sheet and plate industry emphasize increased adoption of advanced alloys and eco-friendly production techniques to enhance durability and reduce carbon footprints. Innovations in manufacturing, such as precision laser cutting and automation, boost efficiency and product consistency for both sheet iron and plate iron applications. Growing demand from construction, automotive, and aerospace sectors drives expansion while sustainability initiatives push for recyclable and energy-efficient iron products.

Sheet Iron vs Plate Iron Infographic

materialdif.com

materialdif.com