Annealed iron undergoes a heating and slow cooling process that makes it softer, more ductile, and easier to shape, ideal for applications requiring bending and forming. Tempered iron is heated and then rapidly cooled to increase its hardness and strength, enhancing resistance to wear and impact. Choosing between annealed and tempered iron depends on the balance needed between flexibility and durability for the specific iron pet project.

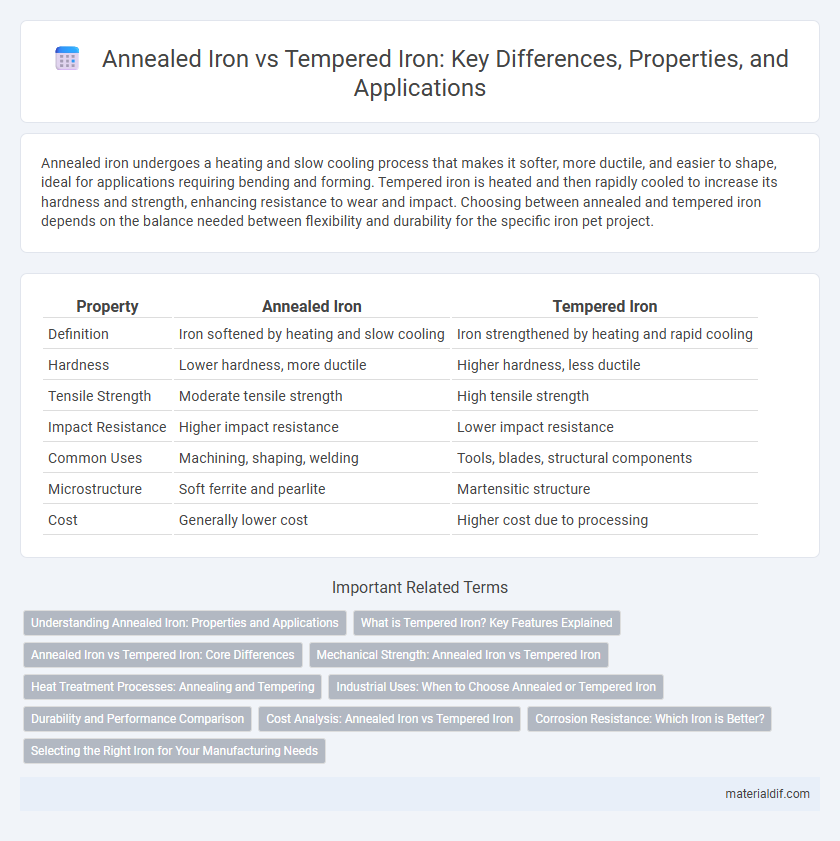

Table of Comparison

| Property | Annealed Iron | Tempered Iron |

|---|---|---|

| Definition | Iron softened by heating and slow cooling | Iron strengthened by heating and rapid cooling |

| Hardness | Lower hardness, more ductile | Higher hardness, less ductile |

| Tensile Strength | Moderate tensile strength | High tensile strength |

| Impact Resistance | Higher impact resistance | Lower impact resistance |

| Common Uses | Machining, shaping, welding | Tools, blades, structural components |

| Microstructure | Soft ferrite and pearlite | Martensitic structure |

| Cost | Generally lower cost | Higher cost due to processing |

Understanding Annealed Iron: Properties and Applications

Annealed iron undergoes a heat treatment process that softens the metal, enhancing its ductility and reducing internal stresses, making it ideal for applications requiring extensive shaping or bending. Its improved malleability and reduced hardness distinguish it from tempered iron, which is harder and more brittle due to rapid cooling. Common uses of annealed iron include manufacturing structural components, metalworking tasks, and decorative items where flexibility and workability are essential.

What is Tempered Iron? Key Features Explained

Tempered iron is a type of iron that has undergone a heat treatment process to enhance its hardness and strength while maintaining ductility. Key features include improved wear resistance, increased tensile strength, and reduced brittleness compared to annealed iron. This process typically involves heating the iron to a specific temperature and then cooling it rapidly to achieve the desired mechanical properties.

Annealed Iron vs Tempered Iron: Core Differences

Annealed iron undergoes a heat treatment process where it is slowly cooled to soften the metal, enhancing its ductility and reducing internal stresses. Tempered iron is heated to a moderate temperature and then cooled rapidly to increase its hardness and strength while maintaining some toughness. The core difference lies in annealed iron being more malleable and easier to work with, whereas tempered iron offers greater durability and resistance to wear.

Mechanical Strength: Annealed Iron vs Tempered Iron

Annealed iron exhibits lower mechanical strength due to its softened, ductile microstructure achieved through controlled cooling, enhancing malleability but reducing hardness and tensile strength. Tempered iron, subjected to heat treatment and rapid cooling, significantly improves mechanical strength by increasing hardness, yield strength, and resistance to deformation. The tempered state optimizes the balance between toughness and strength, making it more suitable for structural applications requiring enhanced durability and load-bearing capacity.

Heat Treatment Processes: Annealing and Tempering

Annealed iron undergoes a heat treatment process where it is slowly cooled after being heated to a specific temperature, resulting in reduced hardness and increased ductility for improved machinability. Tempered iron is heated to a temperature below its critical point and then rapidly cooled, enhancing strength and toughness while relieving internal stresses from prior quenching. These distinct heat treatment processes optimize iron's mechanical properties to suit various industrial applications.

Industrial Uses: When to Choose Annealed or Tempered Iron

Annealed iron offers improved ductility and reduced hardness, making it ideal for industrial applications requiring easy shaping and welding, such as automotive body panels and intricate metalworking. Tempered iron provides enhanced strength and wear resistance, suitable for heavy-duty machinery parts and structural components subjected to high stress. Choosing between annealed and tempered iron depends on the balance between flexibility needs and mechanical durability in specific manufacturing processes.

Durability and Performance Comparison

Annealed iron exhibits enhanced ductility due to its softening heat treatment, making it less durable under mechanical stress compared to tempered iron, which undergoes controlled cooling to increase hardness and tensile strength. Tempered iron offers superior resistance to wear and mechanical deformation, ensuring longer lifespan in demanding applications. Performance-wise, tempered iron is ideal for structural components requiring high impact resistance, whereas annealed iron suits applications needing flexibility and ease of machining.

Cost Analysis: Annealed Iron vs Tempered Iron

Annealed iron is generally more cost-effective due to its simpler heat treatment process, which involves slow cooling to reduce hardness and increase ductility, making it ideal for applications requiring flexibility but less mechanical strength. Tempered iron, subjected to controlled reheating and rapid cooling, incurs higher production costs but offers improved tensile strength and hardness, justifying the expense in structural or wear-resistant applications. Evaluating long-term performance against initial costs is crucial for selecting annealed or tempered iron in budget-sensitive industrial projects.

Corrosion Resistance: Which Iron is Better?

Annealed iron exhibits lower corrosion resistance due to its softer, more ductile structure that is prone to oxidation and rust formation in humid environments. Tempered iron, with its enhanced hardness and internal stress relief from heat treatment, improves resistance to wear and corrosion by forming a more stable oxide layer. For applications requiring superior corrosion resistance, tempered iron generally outperforms annealed iron, making it the better choice for durability in corrosive conditions.

Selecting the Right Iron for Your Manufacturing Needs

Annealed iron offers enhanced ductility and reduced hardness due to its slow cooling process, making it ideal for applications requiring extensive shaping and bending. Tempered iron, subjected to controlled heat treatment, provides increased strength and resistance to wear, suitable for components needing durability under stress. Selecting the right iron depends on balancing flexibility with strength, considering specific manufacturing requirements like malleability for forming or toughness for structural parts.

Annealed Iron vs Tempered Iron Infographic

materialdif.com

materialdif.com