Annealing iron involves heating it to a specific temperature and then cooling it slowly, which softens the metal and improves its ductility and toughness. Quenching, on the other hand, rapidly cools heated iron by immersion in water or oil, resulting in increased hardness and strength but reduced ductility. The choice between annealing and quenching affects the iron's microstructure, mechanical properties, and suitability for various industrial applications.

Table of Comparison

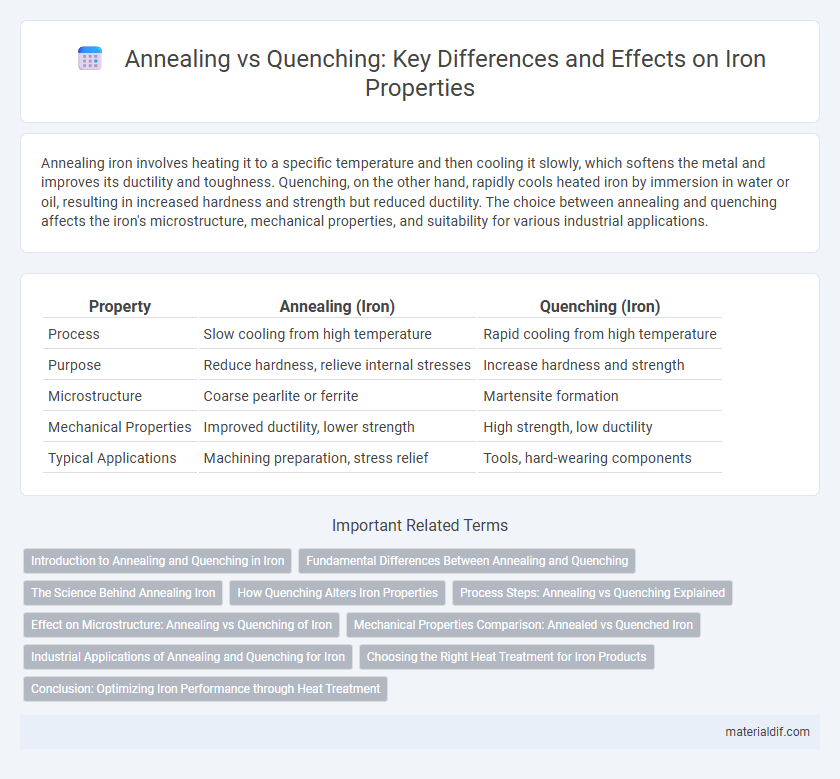

| Property | Annealing (Iron) | Quenching (Iron) |

|---|---|---|

| Process | Slow cooling from high temperature | Rapid cooling from high temperature |

| Purpose | Reduce hardness, relieve internal stresses | Increase hardness and strength |

| Microstructure | Coarse pearlite or ferrite | Martensite formation |

| Mechanical Properties | Improved ductility, lower strength | High strength, low ductility |

| Typical Applications | Machining preparation, stress relief | Tools, hard-wearing components |

Introduction to Annealing and Quenching in Iron

Annealing in iron involves heating the metal above its critical temperature followed by slow cooling, which refines its microstructure and enhances ductility. Quenching rapidly cools heated iron in water or oil, producing a hard but brittle structure known as martensite. These heat treatment processes fundamentally alter iron's physical properties, balancing hardness and toughness for various industrial applications.

Fundamental Differences Between Annealing and Quenching

Annealing and quenching are heat treatment processes used to alter the microstructure of iron to achieve different mechanical properties. Annealing involves heating iron to a specific temperature and then cooling it slowly to increase ductility and reduce hardness, promoting a softer and more workable material. Quenching, by contrast, rapidly cools heated iron, typically in water or oil, to increase hardness and strength by trapping austenite in a martensitic phase.

The Science Behind Annealing Iron

Annealing iron involves heating the metal to a specific temperature, generally between 700degC and 900degC, allowing the atomic structure to rearrange into a more stable, low-stress configuration. This controlled cooling process reduces hardness and brittleness by transforming the microstructure from martensite or pearlite into softer ferrite and cementite phases. The science behind annealing iron is rooted in its ability to relieve internal stresses and promote ductility through recrystallization and phase transformation within the iron-carbon system.

How Quenching Alters Iron Properties

Quenching transforms iron by rapidly cooling it from a high temperature, which increases hardness and strength due to the formation of martensite. This process reduces ductility and toughness compared to annealed iron, which is cooled slowly to enhance softness and malleability. Quenching creates internal stresses that can improve wear resistance but may also cause brittleness and potential cracking.

Process Steps: Annealing vs Quenching Explained

Annealing involves heating iron to a specific temperature, holding it to allow recrystallization, and then cooling it slowly to remove internal stresses and soften the metal. Quenching requires heating the iron to a high temperature followed by rapid cooling in water, oil, or air to increase hardness and strength by transforming its microstructure into martensite. The slow cooling in annealing promotes ductility, while quenching's fast cooling enhances brittleness and hardness.

Effect on Microstructure: Annealing vs Quenching of Iron

Annealing of iron results in a coarse, equiaxed grain structure by allowing atoms to diffuse and relieve internal stresses, promoting the formation of soft, ductile ferrite and pearlite phases. Quenching rapidly cools iron, trapping carbon atoms in a supersaturated solution and producing a hard, brittle martensitic microstructure with distorted body-centered tetragonal lattice. The contrast in microstructures significantly influences mechanical properties, with annealed iron exhibiting enhanced toughness and quenching yielding increased hardness.

Mechanical Properties Comparison: Annealed vs Quenched Iron

Annealed iron exhibits improved ductility and reduced hardness due to its coarse pearlitic or ferritic microstructure, making it more malleable and less prone to brittle failure. Quenched iron, however, undergoes rapid cooling that transforms its microstructure into martensite, significantly increasing hardness and tensile strength but decreasing toughness and ductility. The mechanical properties of annealed vs quenched iron demonstrate a trade-off between softness with high plasticity and hardness with increased brittleness.

Industrial Applications of Annealing and Quenching for Iron

Annealing improves iron's ductility and reduces hardness, making it ideal for industrial applications such as metal forming, machining, and welding, where enhanced workability is critical. Quenching rapidly increases iron's hardness and strength, making it suitable for manufacturing cutting tools, gears, and structural components requiring high wear resistance. Industries utilize annealing for processes demanding flexibility and uniformity, while quenching is preferred for parts exposed to high stress and wear in automotive and heavy machinery sectors.

Choosing the Right Heat Treatment for Iron Products

Selecting the appropriate heat treatment for iron products depends on desired mechanical properties and application requirements. Annealing softens iron by heating it to a specific temperature and allowing slow cooling, enhancing ductility and reducing internal stresses. Quenching involves rapid cooling from high temperature, increasing hardness and strength but potentially causing brittleness, making it ideal for wear-resistant tools.

Conclusion: Optimizing Iron Performance through Heat Treatment

Choosing between annealing and quenching depends on the desired mechanical properties of iron; annealing enhances ductility and reduces internal stresses, whereas quenching increases hardness and strength by forming martensite. Precise control of cooling rates and temperatures is critical to achieving optimal microstructure and performance in iron-based components. Tailoring heat treatment processes ensures improved wear resistance, durability, and suitability for specific industrial applications, maximizing iron's potential.

Annealing vs Quenching (Iron) Infographic

materialdif.com

materialdif.com