Pig iron is a crude form of iron produced by smelting iron ore in a blast furnace, characterized by its high carbon content, making it hard but brittle. Wrought iron, on the other hand, contains very low carbon levels and is known for its ductility, malleability, and resistance to corrosion. These distinct properties make wrought iron ideal for decorative metalwork and structural applications, while pig iron serves as a raw material for steelmaking.

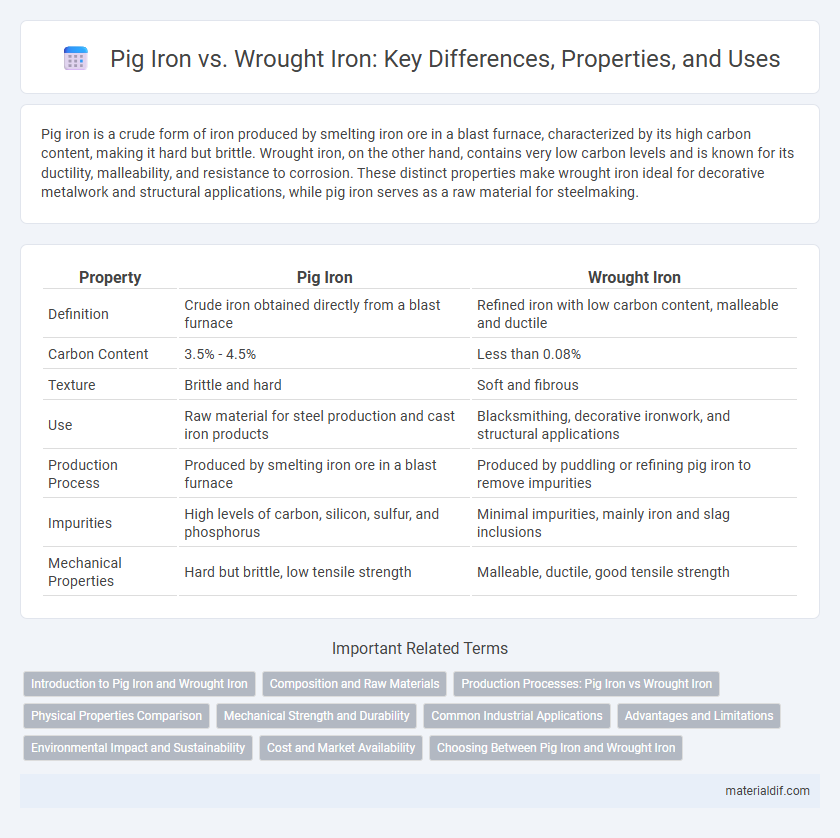

Table of Comparison

| Property | Pig Iron | Wrought Iron |

|---|---|---|

| Definition | Crude iron obtained directly from a blast furnace | Refined iron with low carbon content, malleable and ductile |

| Carbon Content | 3.5% - 4.5% | Less than 0.08% |

| Texture | Brittle and hard | Soft and fibrous |

| Use | Raw material for steel production and cast iron products | Blacksmithing, decorative ironwork, and structural applications |

| Production Process | Produced by smelting iron ore in a blast furnace | Produced by puddling or refining pig iron to remove impurities |

| Impurities | High levels of carbon, silicon, sulfur, and phosphorus | Minimal impurities, mainly iron and slag inclusions |

| Mechanical Properties | Hard but brittle, low tensile strength | Malleable, ductile, good tensile strength |

Introduction to Pig Iron and Wrought Iron

Pig iron is a crude form of iron produced directly from iron ore in a blast furnace, characterized by high carbon content (about 3.5-4.5%) which makes it brittle and unsuitable for most applications. Wrought iron, on the other hand, contains very low carbon (less than 0.08%) and is produced by repeatedly heating and working pig iron to remove impurities, resulting in a tough, malleable, and corrosion-resistant metal. The distinct production methods and carbon levels of pig iron and wrought iron determine their physical properties and suitability for various industrial and construction uses.

Composition and Raw Materials

Pig iron is primarily composed of about 92-95% iron, with high carbon content (3.5-4.5%) and impurities such as silicon, manganese, sulfur, and phosphorus, derived from smelting iron ore in a blast furnace using coke and limestone. Wrought iron contains less than 0.1% carbon and minimal impurities, produced by repeatedly heating and working pig iron or iron ore, which results in fibrous slag inclusions that give it toughness. The raw materials for pig iron focus on iron ore, coke, and flux, while wrought iron relies on refined pig iron or direct ore processing with careful control of impurities.

Production Processes: Pig Iron vs Wrought Iron

Pig iron production involves smelting iron ore in a blast furnace using coke and limestone, resulting in a high-carbon, brittle material suitable as an intermediate for steelmaking. Wrought iron is produced by repeatedly heating and working pig iron to reduce carbon content and impurities, often using a finery forge or puddling process, yielding a malleable and ductile product. The distinct methods lead to pig iron's hardness and brittleness, while wrought iron's refined structure offers superior toughness and corrosion resistance.

Physical Properties Comparison

Pig iron contains about 3.5-4.5% carbon, making it hard and brittle with a coarse crystalline structure, whereas wrought iron has less than 0.1% carbon, resulting in a tough, malleable, and fibrous texture. Pig iron typically has a higher density around 7.2 g/cm3 and is relatively brittle, while wrought iron's density is approximately 7.0 g/cm3 with excellent ductility and corrosion resistance due to its slag inclusions. The physical property differences make pig iron suitable for further refining, while wrought iron is ideal for applications requiring durability and workability.

Mechanical Strength and Durability

Pig iron exhibits high carbon content, resulting in brittleness and lower mechanical strength compared to wrought iron. Wrought iron contains minimal carbon, which provides superior ductility, tensile strength, and durability under mechanical stress. The fibrous slag inclusions in wrought iron enhance its toughness, making it ideal for applications requiring prolonged wear resistance.

Common Industrial Applications

Pig iron, characterized by high carbon content and brittleness, is primarily used as a raw material in steelmaking and foundry castings due to its ease of melting and refining. Wrought iron, with its low carbon content and fibrous texture, excels in applications requiring malleability and corrosion resistance, such as decorative ironwork, fencing, and structural components in construction. The industrial choice between pig iron and wrought iron depends on the required mechanical properties and subsequent processing methods for producing durable iron-based products.

Advantages and Limitations

Pig iron, with its high carbon content around 3.5-4.5%, offers excellent hardness and strength, making it ideal for casting and industrial applications. Wrought iron contains less than 0.1% carbon, providing superior ductility, corrosion resistance, and ease of welding, which benefits structural and ornamental uses. However, pig iron's brittleness limits its use in tension-bearing applications, while wrought iron's lower strength reduces its effectiveness in heavy-duty construction.

Environmental Impact and Sustainability

Pig iron production involves high energy consumption and significant carbon emissions due to its reliance on blast furnaces and coke, contributing substantially to environmental degradation. Wrought iron, typically produced through reheating and hammering pig iron, has a lower environmental footprint because it uses recycled materials and requires less energy in its refining process. Sustainable practices in wrought iron manufacturing, such as scrap utilization, enhance resource efficiency and reduce industrial waste compared to the intensive extraction and smelting involved in pig iron production.

Cost and Market Availability

Pig iron is generally more affordable than wrought iron due to its simpler production process and lower purity levels, making it widely available in bulk markets. Wrought iron, valued for its high purity and superior malleability, commands a higher price and is less commonly available, typically restricted to specialized suppliers. Market availability of pig iron supports large-scale industrial use, while wrought iron is favored for decorative and restoration projects despite its limited supply.

Choosing Between Pig Iron and Wrought Iron

Choosing between pig iron and wrought iron depends on the intended use and required properties; pig iron contains higher carbon content, making it hard and brittle, suitable primarily for further refining or casting. Wrought iron features low carbon content, offering excellent ductility, corrosion resistance, and machinability, ideal for decorative ironwork, tools, and structural applications. Understanding the carbon content and mechanical characteristics is essential for selecting the appropriate iron type for manufacturing or construction projects.

Pig Iron vs Wrought Iron Infographic

materialdif.com

materialdif.com