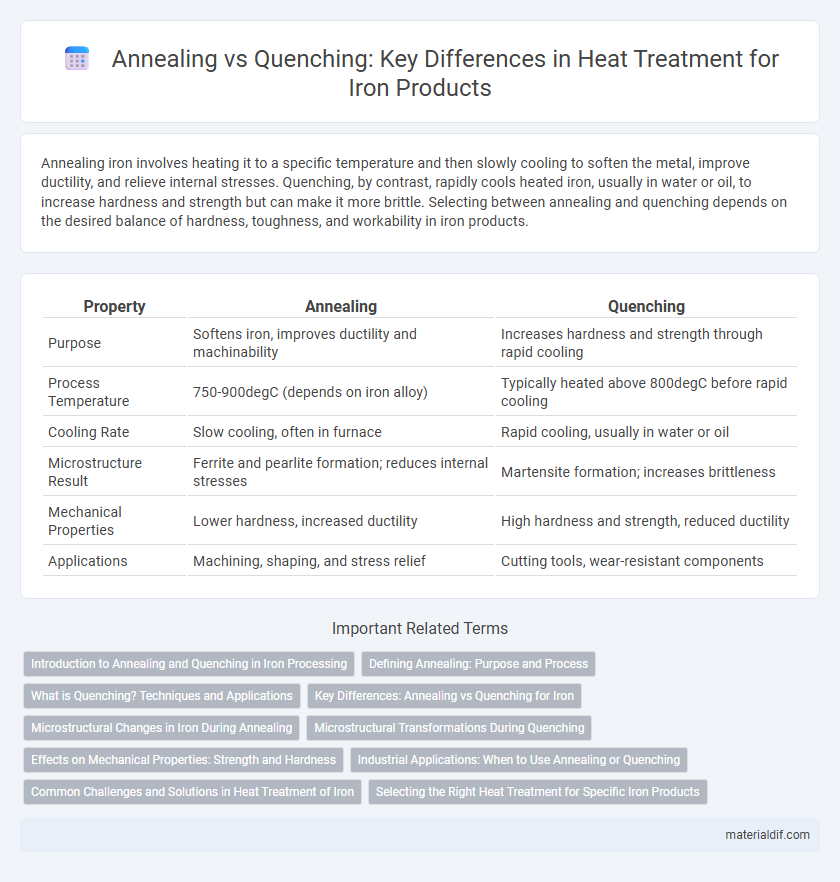

Annealing iron involves heating it to a specific temperature and then slowly cooling to soften the metal, improve ductility, and relieve internal stresses. Quenching, by contrast, rapidly cools heated iron, usually in water or oil, to increase hardness and strength but can make it more brittle. Selecting between annealing and quenching depends on the desired balance of hardness, toughness, and workability in iron products.

Table of Comparison

| Property | Annealing | Quenching |

|---|---|---|

| Purpose | Softens iron, improves ductility and machinability | Increases hardness and strength through rapid cooling |

| Process Temperature | 750-900degC (depends on iron alloy) | Typically heated above 800degC before rapid cooling |

| Cooling Rate | Slow cooling, often in furnace | Rapid cooling, usually in water or oil |

| Microstructure Result | Ferrite and pearlite formation; reduces internal stresses | Martensite formation; increases brittleness |

| Mechanical Properties | Lower hardness, increased ductility | High hardness and strength, reduced ductility |

| Applications | Machining, shaping, and stress relief | Cutting tools, wear-resistant components |

Introduction to Annealing and Quenching in Iron Processing

Annealing in iron processing involves heating the metal to a specific temperature and then cooling it slowly, which reduces hardness, relieves internal stresses, and improves ductility. Quenching, by contrast, entails rapidly cooling heated iron, typically in water or oil, to increase hardness and strength by trapping carbon in a martensitic structure. These heat treatment methods are critical for tailoring the mechanical properties of iron products for various industrial applications.

Defining Annealing: Purpose and Process

Annealing is a heat treatment process for iron products involving heating the metal to a specific temperature followed by slow cooling, aimed at relieving internal stresses and enhancing ductility. This controlled temperature cycle refines the microstructure, reduces hardness, and improves machinability. The primary purpose of annealing is to restore workability and toughness after deformation or casting.

What is Quenching? Techniques and Applications

Quenching is a rapid cooling process for iron products, typically involving immersion in water, oil, or air to alter the metal's microstructure and enhance hardness. Common quenching techniques include water quenching for maximum hardness, oil quenching to reduce thermal shock, and air quenching for slower cooling rates. This process is widely applied in manufacturing cutting tools, gears, and automotive components to improve strength and wear resistance.

Key Differences: Annealing vs Quenching for Iron

Annealing iron involves heating the metal to a specific temperature and then slowly cooling it to reduce hardness and increase ductility, promoting a uniform grain structure. Quenching iron entails rapid cooling, usually by immersion in water or oil, to increase hardness and strength by forming martensitic or bainitic microstructures. The key differences lie in cooling rate and resulting mechanical properties: annealing enhances malleability and reduces internal stresses, while quenching maximizes hardness but can increase brittleness.

Microstructural Changes in Iron During Annealing

Annealing iron involves heating the metal to a specific temperature and then cooling it slowly to alter its microstructure, resulting in the formation of coarse pearlite and ferrite phases that enhance ductility and reduce hardness. This process helps to relieve internal stresses, refine grain size, and increase toughness by transforming martensitic or bainitic structures back into softer, equilibrium phases. In contrast to quenching, which rapidly cools iron to trap carbon atoms in a supersaturated solution forming hard martensite, annealing promotes a more uniform and stable microstructure for improved machinability and structural integrity.

Microstructural Transformations During Quenching

Quenching of iron products rapidly cools the metal, causing the austenite phase to transform into martensite, a hard and brittle microstructure characterized by a body-centered tetragonal lattice. This transformation inhibits the formation of pearlite or ferrite, which would form during slower cooling like annealing. The resultant martensitic microstructure significantly increases hardness and strength while reducing ductility compared to the softer microstructures obtained through annealing.

Effects on Mechanical Properties: Strength and Hardness

Annealing iron products decreases internal stresses, resulting in enhanced ductility and reduced hardness while slightly lowering strength, which improves machinability and toughness. Quenching rapidly cools iron, significantly increasing hardness and tensile strength due to the formation of martensite, but this also leads to brittleness and decreased ductility. The choice between annealing and quenching depends on desired mechanical properties, balancing hardness, strength, and flexibility in iron-based materials.

Industrial Applications: When to Use Annealing or Quenching

Annealing is used in industrial applications where iron products require improved ductility, reduced hardness, and enhanced machinability, such as in metal forming or welding processes. Quenching is preferred when high strength and hardness are needed, like in the manufacturing of cutting tools, gears, and automotive components. Selecting between annealing and quenching depends on balancing mechanical properties for specific industrial uses, ensuring optimal performance and durability of iron products.

Common Challenges and Solutions in Heat Treatment of Iron

Annealing of iron often faces challenges such as uneven grain growth and internal stresses, which can lead to distortion; precise temperature control and slow cooling rates mitigate these issues by promoting uniform microstructure. Quenching presents risks like cracking and excessive hardness due to rapid cooling, which are addressed through controlled quench media and subsequent tempering processes to balance strength and ductility. Optimizing furnace atmosphere and using advanced thermal cycles enhance both annealing and quenching outcomes by reducing oxidation and preserving desired mechanical properties.

Selecting the Right Heat Treatment for Specific Iron Products

Selecting the right heat treatment for iron products depends on desired mechanical properties and application requirements. Annealing improves ductility and reduces hardness by heating iron to a specific temperature followed by slow cooling, making it ideal for machining and forming processes. Quenching, involving rapid cooling from high temperatures, increases hardness and strength, suitable for wear-resistant components but can introduce brittleness if not tempered properly.

Annealing vs Quenching (for iron products) Infographic

materialdif.com

materialdif.com