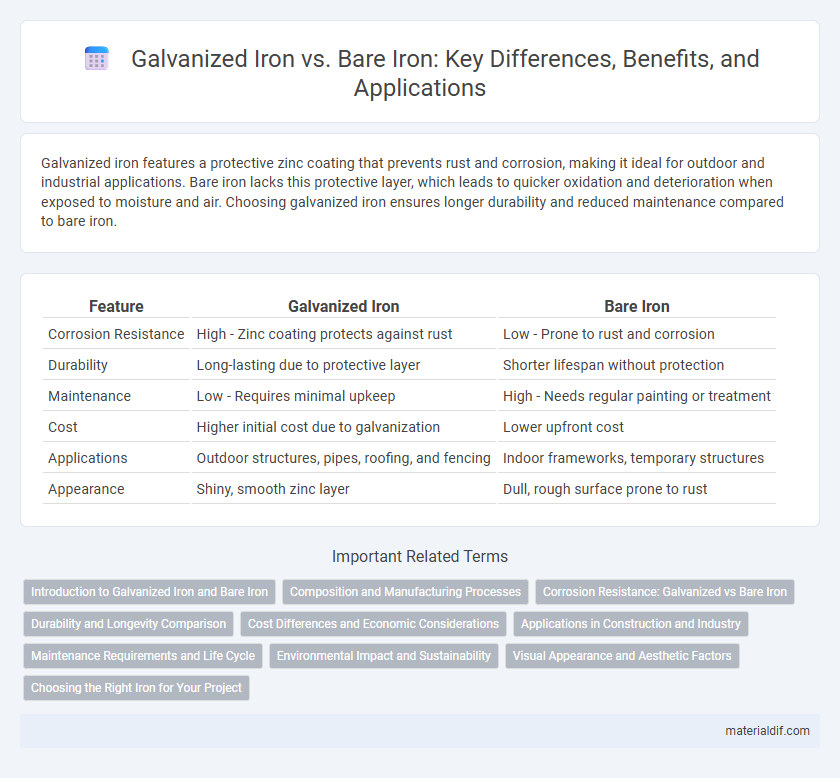

Galvanized iron features a protective zinc coating that prevents rust and corrosion, making it ideal for outdoor and industrial applications. Bare iron lacks this protective layer, which leads to quicker oxidation and deterioration when exposed to moisture and air. Choosing galvanized iron ensures longer durability and reduced maintenance compared to bare iron.

Table of Comparison

| Feature | Galvanized Iron | Bare Iron |

|---|---|---|

| Corrosion Resistance | High - Zinc coating protects against rust | Low - Prone to rust and corrosion |

| Durability | Long-lasting due to protective layer | Shorter lifespan without protection |

| Maintenance | Low - Requires minimal upkeep | High - Needs regular painting or treatment |

| Cost | Higher initial cost due to galvanization | Lower upfront cost |

| Applications | Outdoor structures, pipes, roofing, and fencing | Indoor frameworks, temporary structures |

| Appearance | Shiny, smooth zinc layer | Dull, rough surface prone to rust |

Introduction to Galvanized Iron and Bare Iron

Galvanized iron is steel coated with a layer of zinc to prevent rust and corrosion, significantly extending its durability in outdoor and industrial environments. Bare iron, also known as plain iron or untreated iron, lacks protective coatings and is more susceptible to oxidation and rust when exposed to moisture and air. The zinc layer in galvanized iron acts as a sacrificial anode, providing cathodic protection and enhancing the lifespan of iron products compared to bare iron.

Composition and Manufacturing Processes

Galvanized iron is composed of a carbon steel base coated with a thin layer of zinc, applied through hot-dip galvanizing or electro-galvanizing processes to enhance corrosion resistance. Bare iron primarily consists of pure iron or low-carbon steel without any protective coating, making it vulnerable to rust when exposed to moisture and air. The hot-dip galvanizing process involves immersing iron in molten zinc, forming a metallurgical bond, whereas bare iron is typically produced through casting or rolling without additional surface treatment.

Corrosion Resistance: Galvanized vs Bare Iron

Galvanized iron features a zinc coating that significantly enhances corrosion resistance by forming a protective barrier against moisture and oxygen, preventing rust formation. Bare iron lacks this protective layer, making it highly susceptible to oxidation and rust when exposed to environmental elements. The zinc coating in galvanized iron provides sacrificial protection, corroding first and thus extending the lifespan of the underlying iron.

Durability and Longevity Comparison

Galvanized iron offers superior durability and longevity compared to bare iron due to its protective zinc coating, which prevents rust and corrosion. Bare iron, lacking this coating, is prone to rapid oxidation when exposed to moisture and environmental elements, leading to significant deterioration over time. The zinc layer in galvanized iron not only extends the material's lifespan by several years but also reduces maintenance costs and structural failures in construction and industrial applications.

Cost Differences and Economic Considerations

Galvanized iron typically costs 15-40% more than bare iron due to the additional zinc coating process enhancing corrosion resistance and longevity. The higher initial investment in galvanized iron often results in lower maintenance and replacement expenses, leading to superior long-term economic value, especially in outdoor or humid environments. Choosing bare iron may reduce upfront material costs but increases susceptibility to rust, potentially escalating repair and lifecycle costs over time.

Applications in Construction and Industry

Galvanized iron is extensively used in construction and industrial applications where corrosion resistance is critical, such as roofing, wall panels, and structural framing. Bare iron, lacking a protective zinc coating, is primarily utilized in environments where its strength is prioritized over corrosion resistance, including heavy machinery parts and reinforcement bars in non-corrosive contexts. The choice between galvanized iron and bare iron hinges on environmental exposure and longevity requirements in construction projects and industrial settings.

Maintenance Requirements and Life Cycle

Galvanized iron features a protective zinc coating that significantly reduces rust and corrosion, minimizing maintenance requirements compared to bare iron. Bare iron requires frequent painting and treatments to prevent oxidation, resulting in higher upkeep costs and shorter life cycles. Galvanized iron typically offers a lifespan of 30 to 50 years, while bare iron may last only 10 to 15 years under similar environmental conditions.

Environmental Impact and Sustainability

Galvanized iron offers enhanced durability due to its protective zinc coating, reducing the frequency of replacement and thereby lowering environmental waste compared to bare iron. The zinc layer also prevents rusting, minimizing the release of iron oxides into the environment, which can contaminate soil and water. However, the galvanization process involves energy-intensive zinc extraction and potential heavy metal pollution, requiring careful management to maintain sustainability.

Visual Appearance and Aesthetic Factors

Galvanized iron features a distinctive silvery-gray, matte finish with a speckled, crystalline pattern caused by the zinc coating, offering a clean and uniform appearance that resists rust and corrosion. Bare iron displays a darker, reddish-brown or blackened surface prone to oxidation and rust stains, which can create an uneven, weathered look over time. For applications prioritizing visual appeal and durability, galvanized iron provides a more consistent and aesthetically pleasing finish compared to the raw, untreated appearance of bare iron.

Choosing the Right Iron for Your Project

Galvanized iron features a protective zinc coating that prevents rust and corrosion, making it ideal for outdoor or moisture-exposed projects. Bare iron lacks this coating, offering a lower cost but requiring additional treatment to resist oxidation and wear. Selecting the right material depends on environmental exposure, project durability requirements, and budget constraints.

Galvanized Iron vs Bare Iron Infographic

materialdif.com

materialdif.com