Pig iron is a crude form of iron with high carbon content, typically produced in blast furnaces and used as a raw material for steelmaking. Sponge iron, also known as direct reduced iron (DRI), is obtained by reducing iron ore in its solid state without melting, resulting in a porous, sponge-like structure. The key difference lies in their production methods and carbon content, with pig iron being more brittle and sponge iron offering higher purity and better suitability for electric arc furnace steelmaking.

Table of Comparison

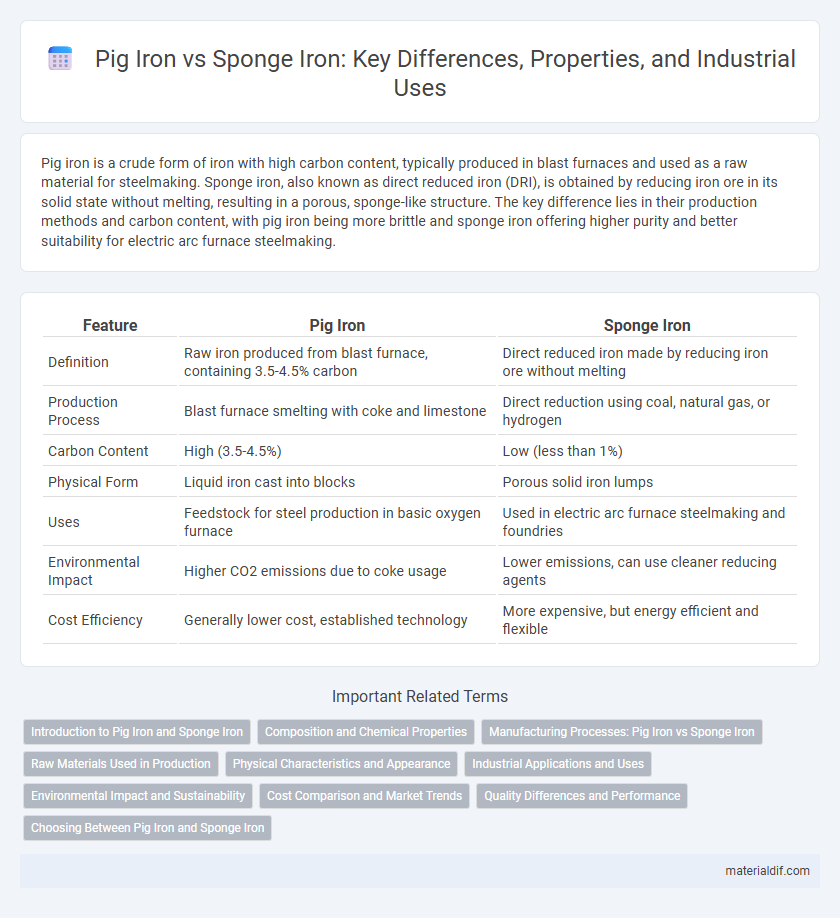

| Feature | Pig Iron | Sponge Iron |

|---|---|---|

| Definition | Raw iron produced from blast furnace, containing 3.5-4.5% carbon | Direct reduced iron made by reducing iron ore without melting |

| Production Process | Blast furnace smelting with coke and limestone | Direct reduction using coal, natural gas, or hydrogen |

| Carbon Content | High (3.5-4.5%) | Low (less than 1%) |

| Physical Form | Liquid iron cast into blocks | Porous solid iron lumps |

| Uses | Feedstock for steel production in basic oxygen furnace | Used in electric arc furnace steelmaking and foundries |

| Environmental Impact | Higher CO2 emissions due to coke usage | Lower emissions, can use cleaner reducing agents |

| Cost Efficiency | Generally lower cost, established technology | More expensive, but energy efficient and flexible |

Introduction to Pig Iron and Sponge Iron

Pig iron is a crude form of iron with high carbon content, typically produced by smelting iron ore in a blast furnace. Sponge iron, also known as direct reduced iron (DRI), is made by reducing iron ore using a gas or coal-based direct reduction process without melting. Both materials serve as essential raw inputs in steel manufacturing, with pig iron being more carbon-rich and sponge iron offering lower impurities.

Composition and Chemical Properties

Pig iron contains about 3-4.5% carbon, along with silicon, manganese, sulfur, and phosphorus, resulting in a brittle structure due to its high carbon content. Sponge iron, produced by direct reduction of iron ore, has a much lower carbon content, typically below 1%, and retains more porous metallic iron with minimal impurities. Chemical properties differ as pig iron's higher carbon makes it less malleable and more reactive to oxidation, while sponge iron's purer form enhances its suitability for steel-making processes.

Manufacturing Processes: Pig Iron vs Sponge Iron

Pig iron is produced through the blast furnace process, where iron ore is smelted with coke and limestone at high temperatures, resulting in a brittle, high-carbon intermediate product. Sponge iron, also known as direct reduced iron (DRI), is manufactured by reducing iron ore using a gas-based or coal-based reducing agent at lower temperatures, preserving its porous and metallic form. The blast furnace method yields pig iron with higher carbon content suitable for further steelmaking, while sponge iron offers a purer iron product ideal for electric arc furnace steel production.

Raw Materials Used in Production

Pig iron is produced primarily from iron ore, coke, and limestone through the blast furnace process, where iron ore is smelted at high temperatures. Sponge iron, also known as direct reduced iron (DRI), is made from direct reduction of iron ore using reducing gases like natural gas or coal-derived syngas, without melting the ore. The raw materials for pig iron emphasize coke and limestone along with iron ore, whereas sponge iron relies heavily on high-quality iron ore and reducing gases, making the production processes distinct in feedstock requirements.

Physical Characteristics and Appearance

Pig iron appears as a brittle, crystalline solid with a high carbon content, typically grayish or bluish in color due to its impurities. Sponge iron, also known as direct reduced iron, has a porous, spongy texture with a gray metallic luster, resulting from the removal of oxygen without melting. The dense, compact form of pig iron contrasts sharply with the irregular, lightweight structure of sponge iron.

Industrial Applications and Uses

Pig iron, with its high carbon content and brittle nature, is primarily used as an intermediate material in steelmaking and foundries, serving as a raw input for producing cast iron and various steel grades. Sponge iron, produced through direct reduction of iron ore, has lower carbon content and higher purity, making it ideal for electric arc furnaces in steel plants and manufacturing high-quality steel products. Industrial applications favor sponge iron for its reduced impurities and energy efficiency, while pig iron remains essential in traditional blast furnace operations and cast iron product fabrication.

Environmental Impact and Sustainability

Pig iron production relies heavily on coke derived from coal, releasing significant CO2 emissions and contributing to air pollution, making it less environmentally sustainable. Sponge iron, produced through direct reduced iron (DRI) processes using natural gas or hydrogen, results in lower carbon emissions and consumes less energy, positioning it as a cleaner alternative. The shift towards sponge iron aligns with global sustainability goals by reducing greenhouse gases and supporting more eco-friendly steelmaking practices.

Cost Comparison and Market Trends

Pig iron typically costs less than sponge iron due to its simpler production process using blast furnaces and lower energy consumption. Market trends indicate rising demand for sponge iron driven by its superior quality and adaptability in electric arc furnace steelmaking despite higher production costs. Price fluctuations in raw materials like iron ore and coal heavily influence both pig iron and sponge iron, with sponge iron markets showing greater sensitivity to environmental regulatory changes.

Quality Differences and Performance

Pig iron contains higher carbon content ranging from 3.5% to 4.5%, resulting in brittleness and lower ductility compared to sponge iron, which typically has less than 1.2% carbon and higher purity. Sponge iron's superior quality arises from its porous structure, allowing for enhanced reactivity and better control during steelmaking, leading to improved mechanical properties in the final product. Performance-wise, sponge iron is preferred for producing steel with consistent strength and flexibility, whereas pig iron is often used for cast iron products due to its hardness but lower tensile strength.

Choosing Between Pig Iron and Sponge Iron

Choosing between pig iron and sponge iron depends on their composition and intended use; pig iron contains higher carbon content, making it brittle and suitable mainly for remelting into steel, while sponge iron offers lower carbon levels and a porous structure ideal for steel production with better control over impurities. Industrial applications prioritize sponge iron for direct steelmaking due to its higher purity and consistent quality, whereas pig iron serves as a crucial raw material in foundries and blast furnaces. Evaluating factors such as carbon content, impurity levels, and end-product requirements guides the selection process between the two materials.

Pig Iron vs Sponge Iron Infographic

materialdif.com

materialdif.com