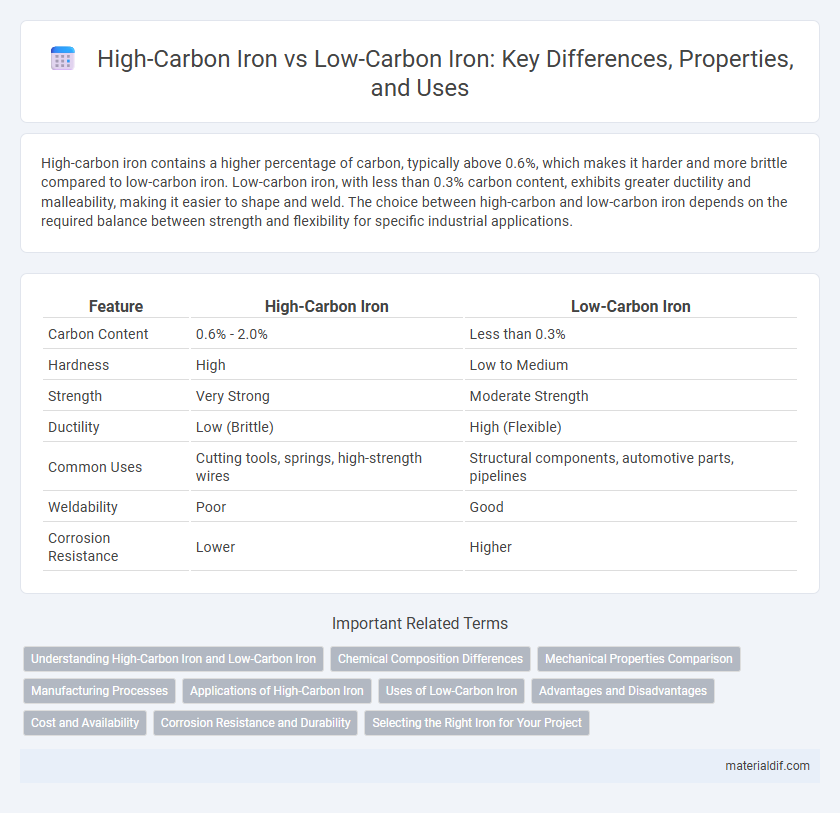

High-carbon iron contains a higher percentage of carbon, typically above 0.6%, which makes it harder and more brittle compared to low-carbon iron. Low-carbon iron, with less than 0.3% carbon content, exhibits greater ductility and malleability, making it easier to shape and weld. The choice between high-carbon and low-carbon iron depends on the required balance between strength and flexibility for specific industrial applications.

Table of Comparison

| Feature | High-Carbon Iron | Low-Carbon Iron |

|---|---|---|

| Carbon Content | 0.6% - 2.0% | Less than 0.3% |

| Hardness | High | Low to Medium |

| Strength | Very Strong | Moderate Strength |

| Ductility | Low (Brittle) | High (Flexible) |

| Common Uses | Cutting tools, springs, high-strength wires | Structural components, automotive parts, pipelines |

| Weldability | Poor | Good |

| Corrosion Resistance | Lower | Higher |

Understanding High-Carbon Iron and Low-Carbon Iron

High-carbon iron contains approximately 0.6% to 2.0% carbon, resulting in increased hardness, strength, and brittleness, making it ideal for cutting tools and wear-resistant applications. Low-carbon iron, with less than 0.3% carbon, offers greater ductility and malleability, suited for structural components and automotive parts where flexibility is essential. The distinct carbon content significantly influences the mechanical properties and industrial uses of iron, with high-carbon variants providing hardness and low-carbon types ensuring toughness.

Chemical Composition Differences

High-carbon iron contains approximately 0.6% to 2.0% carbon, resulting in increased hardness and brittleness, while low-carbon iron has less than 0.3% carbon, offering greater ductility and malleability. The elevated carbon content in high-carbon iron forms cementite (Fe3C), which significantly influences its microstructure and mechanical properties. Conversely, low-carbon iron primarily consists of ferrite, providing enhanced weldability and ease of machining due to its lower carbon concentration.

Mechanical Properties Comparison

High-carbon iron exhibits greater hardness and tensile strength due to its increased carbon content, making it ideal for applications requiring wear resistance and durability. Low-carbon iron offers superior ductility and impact resistance, enabling better formability and toughness in structural components. The mechanical properties vary significantly, with high-carbon iron having higher strength but lower malleability compared to the more flexible and corrosion-resistant low-carbon iron.

Manufacturing Processes

High-carbon iron undergoes a controlled alloying process involving significant carbon infusion, typically exceeding 0.6%, resulting in increased hardness and brittleness suited for cutting tools and wear-resistant applications. Low-carbon iron contains less than 0.3% carbon, produced through basic oxygen furnace or electric arc furnace methods, offering greater ductility and weldability ideal for structural components and automotive bodies. Manufacturing processes differ in temperature control and cooling rates, directly influencing the microstructure, mechanical properties, and application performance of each iron type.

Applications of High-Carbon Iron

High-carbon iron is predominantly used in manufacturing cutting tools, springs, and high-strength wires due to its superior hardness and wear resistance compared to low-carbon iron. Its elevated carbon content enhances tensile strength, making it ideal for applications requiring durable and abrasion-resistant materials. Industries such as automotive, construction, and tooling rely heavily on high-carbon iron for components subjected to significant mechanical stress and strain.

Uses of Low-Carbon Iron

Low-carbon iron, also known as mild steel, is primarily used in construction, automotive manufacturing, and shipbuilding due to its excellent ductility and weldability. Its low carbon content, typically below 0.3%, provides superior malleability, making it ideal for producing structural beams, pipelines, and screws. This form of iron also serves as a base material for making sheets, wires, and various household appliances where strength and flexibility are essential.

Advantages and Disadvantages

High-carbon iron offers superior hardness and wear resistance, making it ideal for cutting tools and machinery parts, but its brittleness limits flexibility and impact resistance. Low-carbon iron provides greater ductility and toughness, allowing for easier shaping and better shock absorption, but it sacrifices some strength and hardness compared to high-carbon variants. Choosing between high-carbon and low-carbon iron depends on balancing the need for durability against malleability in specific industrial applications.

Cost and Availability

High-carbon iron typically costs more due to the added processing required to increase its carbon content, impacting its availability in bulk. Low-carbon iron remains more affordable and widely available, as it involves less complex manufacturing and is sourced more easily from iron ore deposits. This makes low-carbon iron the preferred choice for large-scale industrial applications requiring cost efficiency and consistent supply.

Corrosion Resistance and Durability

High-carbon iron exhibits enhanced hardness and wear resistance but tends to have lower corrosion resistance compared to low-carbon iron due to its microstructure, which can promote rust formation. Low-carbon iron offers superior corrosion resistance and greater ductility, making it more durable in environments exposed to moisture and oxidation. Selecting the appropriate carbon content balances mechanical strength and longevity based on specific application requirements.

Selecting the Right Iron for Your Project

High-carbon iron contains approximately 0.6% to 2.0% carbon, offering superior hardness and strength, making it ideal for tools and cutting instruments requiring durability. Low-carbon iron, with less than 0.3% carbon, provides greater ductility and weldability, suitable for structural components and projects needing flexibility. Selecting the right iron depends on balancing mechanical properties to match project demands such as wear resistance or ease of fabrication.

High-Carbon Iron vs Low-Carbon Iron Infographic

materialdif.com

materialdif.com