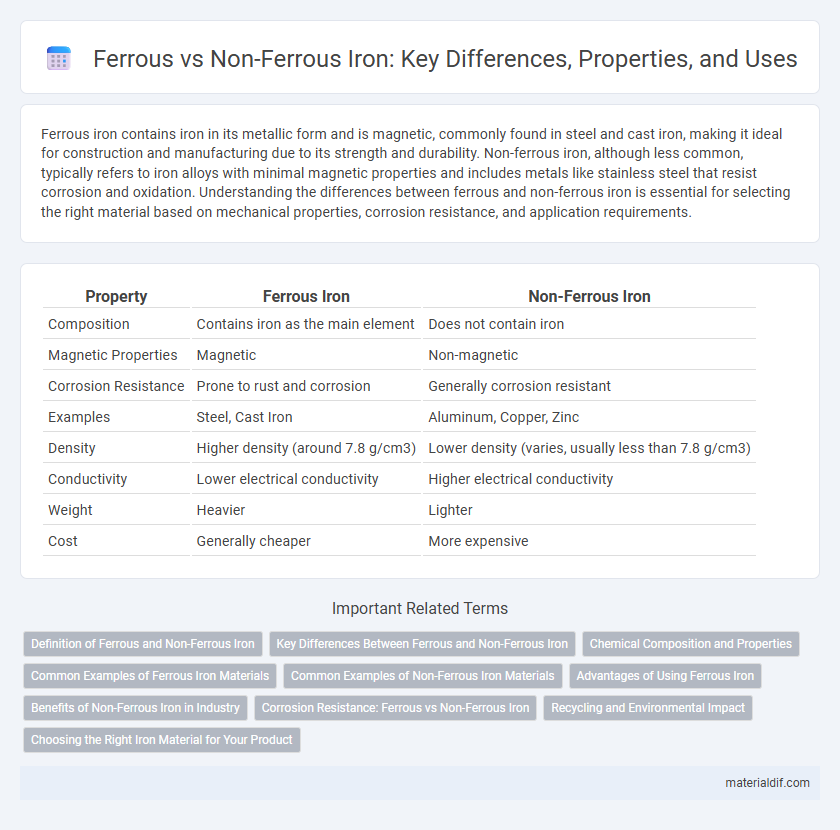

Ferrous iron contains iron in its metallic form and is magnetic, commonly found in steel and cast iron, making it ideal for construction and manufacturing due to its strength and durability. Non-ferrous iron, although less common, typically refers to iron alloys with minimal magnetic properties and includes metals like stainless steel that resist corrosion and oxidation. Understanding the differences between ferrous and non-ferrous iron is essential for selecting the right material based on mechanical properties, corrosion resistance, and application requirements.

Table of Comparison

| Property | Ferrous Iron | Non-Ferrous Iron |

|---|---|---|

| Composition | Contains iron as the main element | Does not contain iron |

| Magnetic Properties | Magnetic | Non-magnetic |

| Corrosion Resistance | Prone to rust and corrosion | Generally corrosion resistant |

| Examples | Steel, Cast Iron | Aluminum, Copper, Zinc |

| Density | Higher density (around 7.8 g/cm3) | Lower density (varies, usually less than 7.8 g/cm3) |

| Conductivity | Lower electrical conductivity | Higher electrical conductivity |

| Weight | Heavier | Lighter |

| Cost | Generally cheaper | More expensive |

Definition of Ferrous and Non-Ferrous Iron

Ferrous iron refers to iron and its alloys that primarily contain iron with magnetic properties and a significant amount of iron content, typically used in construction and manufacturing industries. Non-ferrous iron, on the other hand, is a misnomer as true non-ferrous metals exclude iron; instead, non-ferrous metals are those that do not contain iron, such as aluminum, copper, and zinc, known for their resistance to rust and lightweight characteristics. The distinction between ferrous and non-ferrous metals is critical for applications requiring specific mechanical properties and corrosion resistance.

Key Differences Between Ferrous and Non-Ferrous Iron

Ferrous iron contains iron as its primary component, characterized by magnetic properties and high tensile strength, commonly found in steel and cast iron alloys. Non-ferrous iron lacks iron's magnetic properties and is more resistant to corrosion, including metals like aluminum and copper that do not contain significant amounts of iron. The key differences lie in magnetic behavior, rust resistance, and applications, where ferrous metals are used for structural purposes and non-ferrous metals suit electrical and corrosion-resistant uses.

Chemical Composition and Properties

Ferrous iron primarily contains iron in its elemental state or combined with carbon and small amounts of other metals, forming alloys such as steel and cast iron, which exhibit magnetic properties, high tensile strength, and susceptibility to rusting due to oxidation. Non-ferrous iron materials, although rare, generally refer to iron alloys with significant amounts of non-iron metals like copper, aluminum, or nickel, resulting in enhanced corrosion resistance, non-magnetic behavior, and lower density compared to ferrous counterparts. Chemical composition differences between ferrous and non-ferrous iron influence properties such as conductivity, malleability, and reactivity, dictating their industrial applications and performance under varying environmental conditions.

Common Examples of Ferrous Iron Materials

Common examples of ferrous iron materials include carbon steel, cast iron, and wrought iron, all characterized by high iron content and magnetic properties. These materials are widely used in construction, automotive manufacturing, and heavy machinery due to their strength and durability. Ferrous metals typically contain varying amounts of carbon, which influence their hardness and tensile strength, making them essential for structural and industrial applications.

Common Examples of Non-Ferrous Iron Materials

Non-ferrous iron materials include metals and alloys that do not contain significant amounts of iron, such as aluminum, copper, lead, zinc, and tin. These materials are prized for their resistance to corrosion, lightweight properties, and excellent electrical conductivity, making them essential in electrical wiring, aerospace, and automotive industries. Common examples of non-ferrous metals used include aluminum alloys in aircraft manufacturing, copper in electrical cables, and nickel in stainless steel production.

Advantages of Using Ferrous Iron

Ferrous iron, containing iron as its main component, offers superior strength and durability compared to non-ferrous metals, making it ideal for construction and heavy machinery. Its magnetic properties enable applications in electrical transformers, motors, and generators, where non-ferrous metals lack effectiveness. Ferrous iron is more cost-effective and widely available, ensuring easier recycling and sustainability in industrial processes.

Benefits of Non-Ferrous Iron in Industry

Non-ferrous iron alloys such as stainless steel offer superior corrosion resistance, enhancing durability in industrial applications exposed to harsh environments. These materials typically exhibit higher conductivity and lower weight compared to ferrous iron, improving energy efficiency and ease of handling in manufacturing processes. Non-ferrous iron components also provide better machinability and recyclability, supporting sustainable production practices in sectors like aerospace and automotive engineering.

Corrosion Resistance: Ferrous vs Non-Ferrous Iron

Ferrous iron, containing iron as the primary component, is prone to rust and corrosion when exposed to moisture and oxygen, resulting in structural degradation over time. Non-ferrous iron alloys, often combined with metals like aluminum, copper, or nickel, exhibit superior corrosion resistance due to their inherent oxidation-resistant properties. This makes non-ferrous metals ideal for applications requiring durability in harsh environments, while ferrous metals are typically favored for strength and magnetic properties despite their susceptibility to rust.

Recycling and Environmental Impact

Ferrous iron, containing iron as the main element, is highly recyclable and dominates the recycling industry due to its magnetic properties and ease of separation from waste streams. Non-ferrous metals, although less abundant in iron content, require energy-intensive processes for recycling but offer significant environmental benefits by reducing mining activities. Recycling ferrous and non-ferrous metals lowers greenhouse gas emissions, conserves natural resources, and minimizes landfill waste, playing a crucial role in sustainable metal management.

Choosing the Right Iron Material for Your Product

Ferrous iron contains iron with carbon and is magnetic, making it ideal for construction, automotive, and heavy machinery due to its strength and durability. Non-ferrous iron refers to alloys without significant iron content, offering superior corrosion resistance and electrical conductivity, preferred in electronics and aerospace applications. Selecting between ferrous and non-ferrous iron depends on product requirements for strength, weight, magnetic properties, and environmental resistance to ensure optimal performance and longevity.

Ferrous Iron vs Non-Ferrous Iron Infographic

materialdif.com

materialdif.com