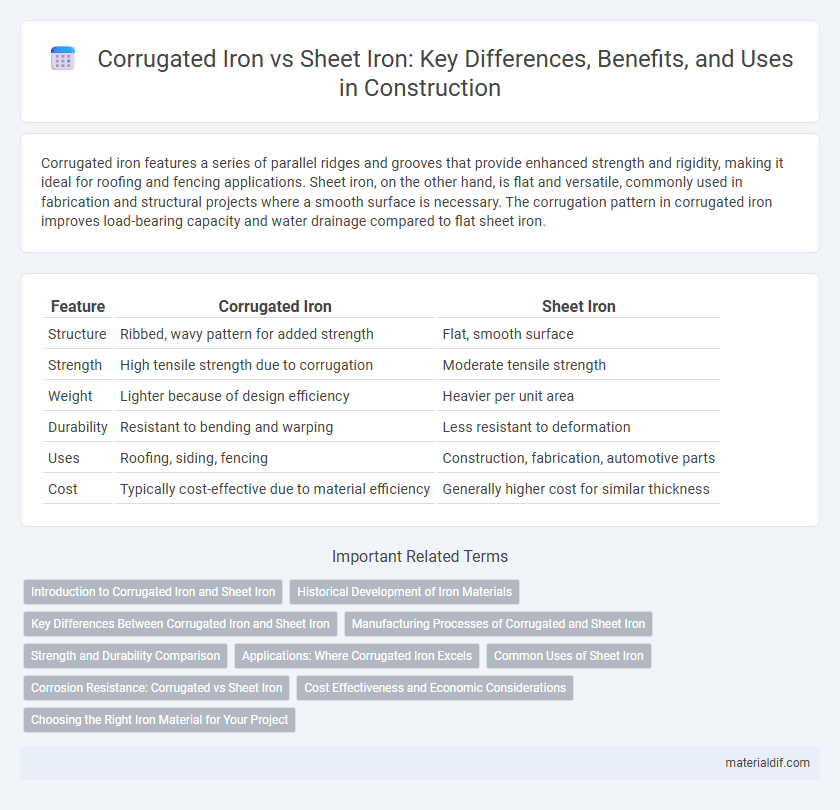

Corrugated iron features a series of parallel ridges and grooves that provide enhanced strength and rigidity, making it ideal for roofing and fencing applications. Sheet iron, on the other hand, is flat and versatile, commonly used in fabrication and structural projects where a smooth surface is necessary. The corrugation pattern in corrugated iron improves load-bearing capacity and water drainage compared to flat sheet iron.

Table of Comparison

| Feature | Corrugated Iron | Sheet Iron |

|---|---|---|

| Structure | Ribbed, wavy pattern for added strength | Flat, smooth surface |

| Strength | High tensile strength due to corrugation | Moderate tensile strength |

| Weight | Lighter because of design efficiency | Heavier per unit area |

| Durability | Resistant to bending and warping | Less resistant to deformation |

| Uses | Roofing, siding, fencing | Construction, fabrication, automotive parts |

| Cost | Typically cost-effective due to material efficiency | Generally higher cost for similar thickness |

Introduction to Corrugated Iron and Sheet Iron

Corrugated iron consists of thin sheets of iron rolled into repetitive ridges and grooves to enhance strength and rigidity, commonly used in roofing and siding applications. In contrast, sheet iron refers to flat, uniform iron sheets without any corrugation, suitable for manufacturing, construction, and industrial uses requiring smooth surfaces. The structural design of corrugated iron improves load-bearing capacity, while sheet iron offers versatile fabrication options.

Historical Development of Iron Materials

Corrugated iron, developed in the 19th century by Henry Palmer, revolutionized construction by providing lightweight, durable roofing material made from hot-dip galvanized sheet iron, which increased corrosion resistance. Sheet iron, originally produced through hammering or rolling wrought iron, served as a fundamental material in early metalworking before the advent of industrial steel manufacturing. The innovation of corrugated iron enhanced structural strength and weatherproofing, significantly influencing building practices during the Industrial Revolution.

Key Differences Between Corrugated Iron and Sheet Iron

Corrugated iron features a wavy, ridged pattern that enhances its structural strength and durability, making it ideal for roofing and siding applications where load resistance is crucial. Sheet iron, on the other hand, is flat and smooth, providing a versatile surface commonly used for general fabrication, automotive parts, and construction elements that require ease of cutting and shaping. The distinct surface texture and rigidity of corrugated iron versus the malleability and uniformity of sheet iron represent primary factors guiding their usage in industrial and architectural projects.

Manufacturing Processes of Corrugated and Sheet Iron

Corrugated iron is manufactured by rolling flat iron sheets through a series of rollers that produce a corrugated or wavy pattern, enhancing strength and rigidity for construction applications. Sheet iron, in contrast, is produced by rolling molten iron into flat, smooth sheets, often followed by annealing to improve ductility and workability. The corrugation process distinguishes corrugated iron by increasing load-bearing capacity, whereas sheet iron remains flat for versatility in fabrication and industrial use.

Strength and Durability Comparison

Corrugated iron features a wavy pattern that significantly enhances its strength and load-bearing capacity compared to flat sheet iron, making it more resistant to bending and deformation under pressure. Sheet iron, while uniform and smooth, lacks the structural reinforcements found in corrugated iron, resulting in lower durability and susceptibility to dents and wear over time. The embossed design of corrugated iron improves resistance to harsh weather conditions, extending its lifespan in construction and roofing applications.

Applications: Where Corrugated Iron Excels

Corrugated iron excels in roofing and siding applications due to its enhanced strength and durability from the corrugated pattern, which provides superior resistance to bending and weather impact compared to flat sheet iron. It is widely used in agricultural buildings, warehouses, and industrial structures where lightweight yet sturdy materials are essential. Sheet iron, while suitable for fabrication and decorative uses, lacks the structural rigidity needed for large-scale exterior cladding.

Common Uses of Sheet Iron

Sheet iron, characterized by its flat, thin form, is commonly used in automotive manufacturing for body panels and structural components due to its strength and malleability. It is also widely employed in roofing, siding, and HVAC ductwork, where durability and corrosion resistance are essential. Additionally, sheet iron serves in the fabrication of appliances, metal furniture, and industrial equipment, leveraging its ability to be easily cut, welded, and painted.

Corrosion Resistance: Corrugated vs Sheet Iron

Corrugated iron provides enhanced corrosion resistance compared to sheet iron due to its increased thickness and protective coatings, which help delay rust formation in harsh weather conditions. The corrugated design also allows for better water runoff, reducing moisture retention that accelerates corrosion. In contrast, sheet iron's flat surface tends to accumulate water, making it more susceptible to rust without additional treatment or maintenance.

Cost Effectiveness and Economic Considerations

Corrugated iron offers greater cost-effectiveness than sheet iron due to its enhanced strength-to-weight ratio, reducing material usage and transportation expenses. Its durability and resistance to bending lower maintenance and replacement costs, making it economically advantageous for roofing and siding applications. Conversely, sheet iron is less expensive upfront but may incur higher long-term costs from increased vulnerability to damage and corrosion.

Choosing the Right Iron Material for Your Project

Corrugated iron offers enhanced strength and durability due to its ridged profile, making it ideal for roofing and siding applications where weather resistance is critical. Sheet iron, being flat and smoother, suits projects requiring ease of cutting and shaping, such as automotive parts and decorative panels. Selecting the right iron depends on factors like structural demands, exposure conditions, and fabrication complexity to ensure optimal performance and longevity.

Corrugated Iron vs Sheet Iron Infographic

materialdif.com

materialdif.com