Iron offers excellent conductivity ideal for electrical applications but is prone to corrosion, especially in humid or salty environments. Protective coatings or alloying elements like chromium enhance corrosion resistance without significantly compromising conductivity. Balancing these properties is crucial for optimizing iron's performance in both structural and electrical uses.

Table of Comparison

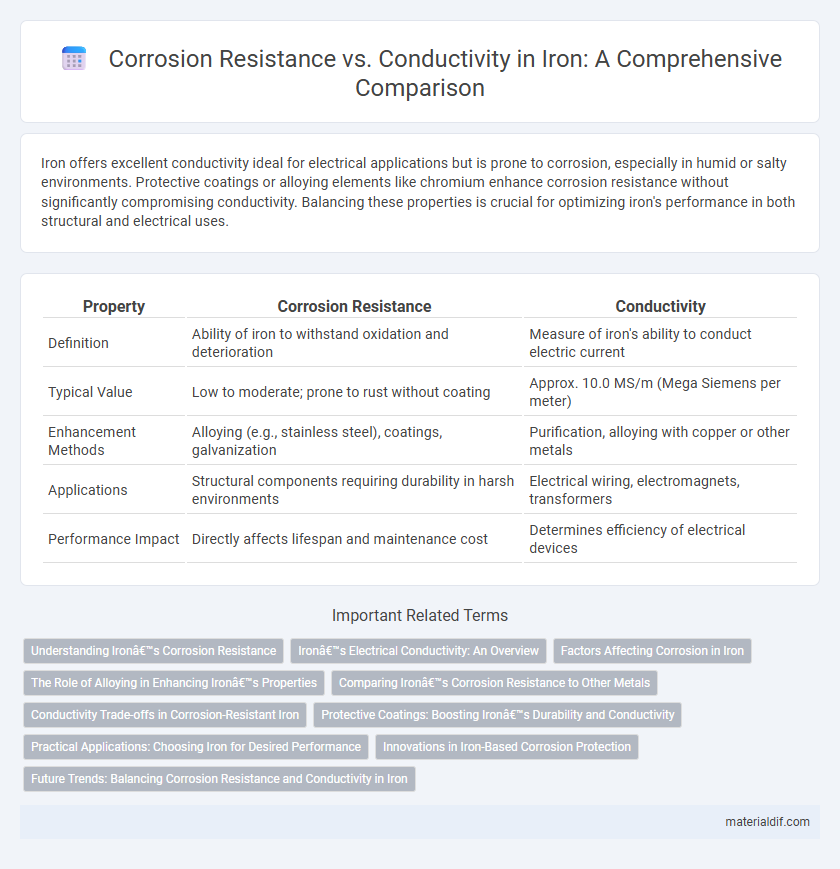

| Property | Corrosion Resistance | Conductivity |

|---|---|---|

| Definition | Ability of iron to withstand oxidation and deterioration | Measure of iron's ability to conduct electric current |

| Typical Value | Low to moderate; prone to rust without coating | Approx. 10.0 MS/m (Mega Siemens per meter) |

| Enhancement Methods | Alloying (e.g., stainless steel), coatings, galvanization | Purification, alloying with copper or other metals |

| Applications | Structural components requiring durability in harsh environments | Electrical wiring, electromagnets, transformers |

| Performance Impact | Directly affects lifespan and maintenance cost | Determines efficiency of electrical devices |

Understanding Iron’s Corrosion Resistance

Iron's corrosion resistance is influenced by its ability to form a protective oxide layer that slows further oxidation, but pure iron has relatively low corrosion resistance compared to alloys like stainless steel. Conductivity in iron is high, enabling efficient electrical and thermal transfer, yet this does not directly enhance its resistance to corrosion. Understanding the balance between iron's conductive properties and its susceptibility to rust is crucial for applications requiring durability and performance in harsh environments.

Iron’s Electrical Conductivity: An Overview

Iron exhibits moderate electrical conductivity, approximately 10 million siemens per meter (S/m), which is lower than that of copper or silver but sufficient for various industrial applications. Its corrosion resistance significantly impacts conductivity over time, as oxidation forms iron oxide layers that increase electrical resistance and hinder efficient electron flow. Protective coatings or alloying elements like chromium enhance corrosion resistance, maintaining iron's conductive properties in harsh environments.

Factors Affecting Corrosion in Iron

Corrosion resistance in iron is primarily influenced by environmental factors such as moisture, oxygen levels, and the presence of corrosive agents like salts or acids, which accelerate oxidation and rust formation. The alloy composition and surface treatments, including galvanization or coating, significantly enhance iron's ability to resist corrosion while maintaining conductivity. Microstructural characteristics, such as grain size and the presence of impurities, also affect the rate of corrosion, balancing iron's electrical conductivity with its durability in various applications.

The Role of Alloying in Enhancing Iron’s Properties

Alloying elements such as chromium, nickel, and molybdenum significantly enhance iron's corrosion resistance while maintaining adequate electrical conductivity for industrial applications. The formation of stable oxide layers due to chromium improves resistance to rust and oxidation without severely compromising conductive pathways. Balancing alloy composition is crucial to achieving optimal performance in environments requiring both durability and efficient electrical conduction.

Comparing Iron’s Corrosion Resistance to Other Metals

Iron exhibits moderate corrosion resistance compared to metals like stainless steel and aluminum, which form protective oxide layers that significantly reduce oxidation. Unlike copper, which maintains conductivity but corrodes slower, iron's susceptibility to rust compromises both its durability and electrical performance in humid environments. Enhancing iron with coatings or alloying elements such as chromium improves its corrosion resistance while partially preserving conductivity.

Conductivity Trade-offs in Corrosion-Resistant Iron

Corrosion-resistant iron alloys typically exhibit reduced electrical conductivity due to the presence of alloying elements like chromium and nickel that enhance corrosion resistance but disrupt electron flow. The trade-off in conductivity arises because these alloying elements create lattice distortions and scattering centers, diminishing the metal's ability to conduct electricity efficiently. Balancing corrosion resistance with acceptable conductivity levels requires precise alloy composition control to optimize performance for applications such as electrical grounding and structural components.

Protective Coatings: Boosting Iron’s Durability and Conductivity

Protective coatings significantly enhance iron's corrosion resistance by forming a barrier against moisture and oxygen, preventing rust formation. These coatings, often composed of zinc, epoxy, or polyurethane, maintain iron's conductivity by reducing surface oxidation, which can impede electron flow. Optimizing coating composition and application methods ensures prolonged durability and efficient electrical performance in iron-based components.

Practical Applications: Choosing Iron for Desired Performance

Iron's corrosion resistance varies significantly with alloy composition, with stainless steel variants offering enhanced protection in environments prone to oxidation, making them ideal for construction and automotive industries. Pure iron exhibits high conductivity but lower resistance to rust, thus it's commonly used in electrical applications where efficient current flow is critical but exposure to moisture is controlled. Selecting iron types balances the trade-off between conductivity and corrosion resistance based on specific application requirements such as marine equipment needing durable, corrosion-resistant alloys versus electrical wiring demanding high conductivity.

Innovations in Iron-Based Corrosion Protection

Innovations in iron-based corrosion protection have significantly enhanced corrosion resistance without compromising electrical conductivity. Advanced coatings and alloying techniques, such as the addition of chromium or nickel, create protective oxide layers that prevent rust formation while maintaining iron's conductive properties. Nanostructured surface treatments and self-healing polymers further improve durability and performance in harsh environments.

Future Trends: Balancing Corrosion Resistance and Conductivity in Iron

Advancements in nanotechnology and alloy design are driving the development of iron-based materials that achieve a precise balance between corrosion resistance and electrical conductivity. Innovative composite coatings and nanostructured iron alloys enhance durability in harsh environments while maintaining efficient electron flow, critical for applications in electronics and infrastructure. Emerging trends emphasize sustainable materials engineering, aiming to optimize iron's multifunctional performance for next-generation industrial technologies.

Corrosion Resistance vs Conductivity Infographic

materialdif.com

materialdif.com