Alloy iron combines iron with other elements such as carbon, manganese, and nickel to enhance strength, hardness, and resistance to corrosion compared to pure iron. Pure iron is softer, more ductile, and has a higher magnetic permeability but lacks the durability required for most industrial applications. The choice between alloy iron and pure iron depends on the specific performance requirements, with alloys favored for construction and manufacturing due to their superior mechanical properties.

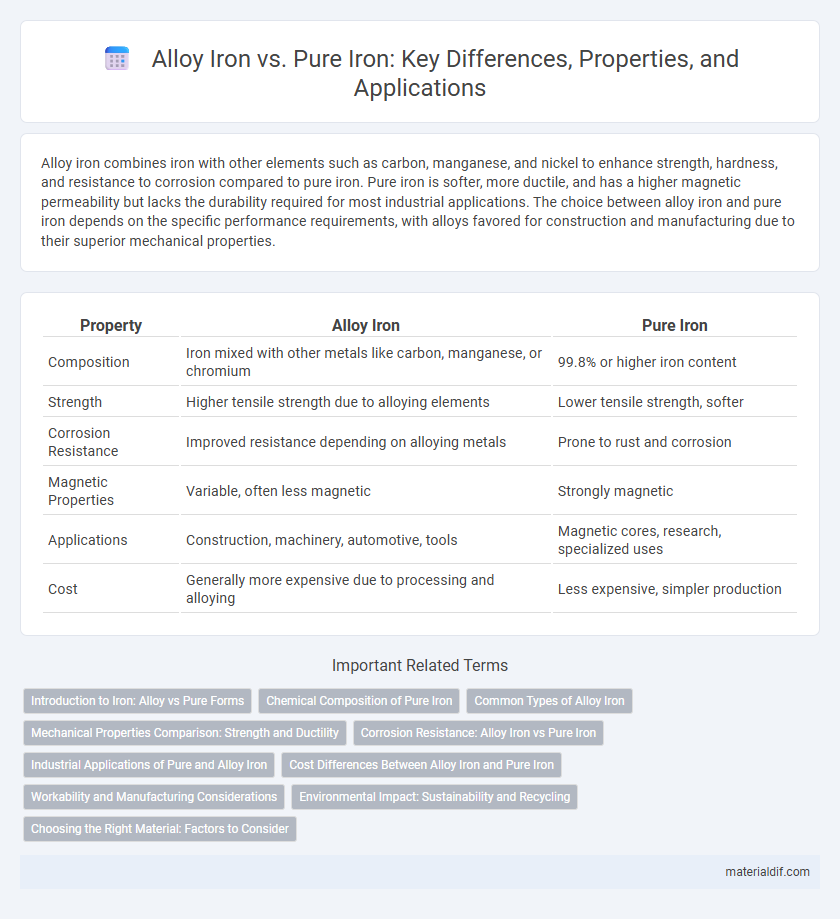

Table of Comparison

| Property | Alloy Iron | Pure Iron |

|---|---|---|

| Composition | Iron mixed with other metals like carbon, manganese, or chromium | 99.8% or higher iron content |

| Strength | Higher tensile strength due to alloying elements | Lower tensile strength, softer |

| Corrosion Resistance | Improved resistance depending on alloying metals | Prone to rust and corrosion |

| Magnetic Properties | Variable, often less magnetic | Strongly magnetic |

| Applications | Construction, machinery, automotive, tools | Magnetic cores, research, specialized uses |

| Cost | Generally more expensive due to processing and alloying | Less expensive, simpler production |

Introduction to Iron: Alloy vs Pure Forms

Alloy iron consists of iron mixed with other elements such as carbon, chromium, and nickel, enhancing its mechanical properties like strength, hardness, and corrosion resistance, which are essential for industrial applications. Pure iron, by contrast, has lower strength and is softer, making it more ductile but less suitable for structural uses. The selection between alloy and pure iron depends largely on the desired balance of durability, flexibility, and resistance to environmental factors.

Chemical Composition of Pure Iron

Pure iron consists primarily of nearly 99.8% iron with minimal impurities such as carbon, sulfur, phosphorus, and oxygen present in trace amounts. Its chemical composition results in a soft, ductile metal with excellent magnetic properties and high malleability. In contrast, alloy iron contains deliberate additions of elements like carbon, manganese, nickel, and chromium to enhance strength, hardness, and corrosion resistance.

Common Types of Alloy Iron

Common types of alloy iron include carbon steel, stainless steel, and tool steel, each enhanced with specific elements like carbon, chromium, and tungsten to improve strength, corrosion resistance, and hardness. Carbon steel contains varying carbon levels to balance ductility and toughness, while stainless steel includes chromium to prevent rust and enhance durability. Tool steel features additives such as vanadium and molybdenum to increase wear resistance and maintain sharpness in cutting applications.

Mechanical Properties Comparison: Strength and Ductility

Alloy iron demonstrates significantly higher strength compared to pure iron due to the intentional addition of elements like carbon, chromium, and nickel, which create a more complex microstructure that resists deformation and improves hardness. Pure iron exhibits superior ductility, allowing it to undergo greater plastic deformation before fracture, making it more malleable and suitable for applications requiring flexibility. The mechanical properties of alloy iron balance enhanced strength with moderate ductility, optimizing performance for structural and engineering uses where both toughness and resistance to wear are critical.

Corrosion Resistance: Alloy Iron vs Pure Iron

Alloy iron exhibits enhanced corrosion resistance compared to pure iron due to the presence of elements such as chromium, nickel, and molybdenum, which form a passive oxide layer that protects the metal surface from oxidation. Pure iron lacks these protective alloying elements, making it more susceptible to rust and environmental degradation. This improved corrosion resistance in alloy iron extends the lifespan and durability of structures and components exposed to harsh conditions.

Industrial Applications of Pure and Alloy Iron

Alloy iron, enhanced with elements like carbon, chromium, and nickel, displays superior strength, corrosion resistance, and hardness, making it ideal for industrial applications such as construction, automotive manufacturing, and heavy machinery. Pure iron, characterized by its high ductility and magnetic properties, is primarily used in electrical transformers, magnetic cores, and specialized chemical equipment where high conductivity and magnetic permeability are essential. The choice between pure and alloy iron depends on the specific industrial requirements for durability, strength, and magnetic performance.

Cost Differences Between Alloy Iron and Pure Iron

Alloy iron typically incurs higher costs than pure iron due to the addition of elements like carbon, nickel, and chromium, which enhance strength and corrosion resistance. The manufacturing process for alloy iron involves more complex refining and quality control, increasing production expenses. Pure iron, being simpler to produce and less engineered, generally offers a lower price point but with limited mechanical properties compared to alloy variants.

Workability and Manufacturing Considerations

Alloy iron offers enhanced workability compared to pure iron due to the presence of elements such as carbon, manganese, and chromium, which improve hardness and tensile strength while maintaining malleability. Manufacturing processes for alloy iron require precise control of temperature and composition to achieve desired mechanical properties, often involving heat treatment and alloying techniques. Pure iron, with its high ductility and low carbon content, is easier to shape but lacks the strength and wear resistance needed for many industrial applications.

Environmental Impact: Sustainability and Recycling

Alloy iron, containing elements like carbon, chromium, and nickel, often requires more intensive energy consumption during production compared to pure iron, leading to a higher carbon footprint. Pure iron's simpler composition facilitates easier recycling processes and lower emissions, enhancing its sustainability profile. The choice between alloy and pure iron significantly influences environmental impact based on factors such as resource extraction, energy use, and recyclability.

Choosing the Right Material: Factors to Consider

Alloy iron offers enhanced strength, corrosion resistance, and durability compared to pure iron, making it ideal for applications requiring high mechanical performance and longevity. Pure iron features superior ductility and magnetic properties but lacks the structural integrity required for heavy-duty use, limiting its applicability in construction and manufacturing. When choosing between alloy and pure iron, factors such as environmental exposure, mechanical stress, and specific functional requirements must be evaluated to ensure material suitability and cost-effectiveness.

Alloy Iron vs Pure Iron Infographic

materialdif.com

materialdif.com