White iron and black iron differ primarily in their carbon content and microstructure, affecting hardness and wear resistance. White iron contains cementite, making it hard and brittle, ideal for wear-resistant applications but difficult to machine. Black iron, or ductile iron, has graphite nodules that provide toughness and machinability, suitable for structural components requiring strength and flexibility.

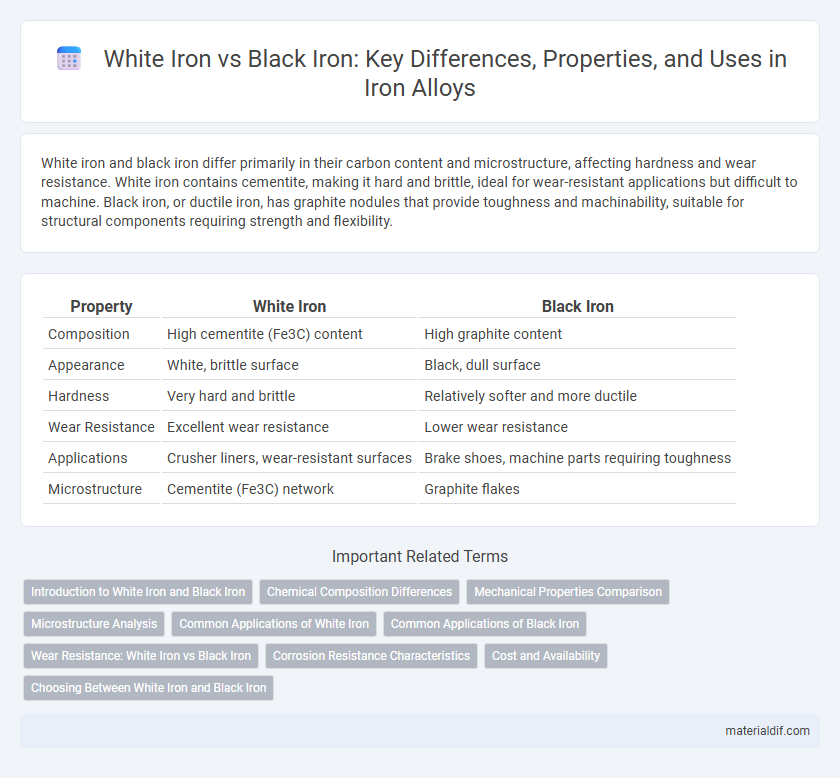

Table of Comparison

| Property | White Iron | Black Iron |

|---|---|---|

| Composition | High cementite (Fe3C) content | High graphite content |

| Appearance | White, brittle surface | Black, dull surface |

| Hardness | Very hard and brittle | Relatively softer and more ductile |

| Wear Resistance | Excellent wear resistance | Lower wear resistance |

| Applications | Crusher liners, wear-resistant surfaces | Brake shoes, machine parts requiring toughness |

| Microstructure | Cementite (Fe3C) network | Graphite flakes |

Introduction to White Iron and Black Iron

White iron and black iron are two distinct types of cast iron characterized by their microstructure and carbon content. White iron features a hard, brittle surface due to cementite formation, providing excellent wear resistance, while black iron, or gray iron, contains graphite flakes that enhance machinability and damping properties. These differences make white iron ideal for abrasive environments and black iron suitable for applications requiring good thermal conductivity and vibration absorption.

Chemical Composition Differences

White iron contains a higher percentage of carbon, typically ranging from 1.8% to 3.6%, combined with significant amounts of cementite (Fe3C), which imparts its hard and brittle nature. Black iron, often referred to as malleable iron, has a lower carbon content with carbon primarily in the form of graphite clusters, resulting from a heat treatment process that decomposes cementite. The carbon distribution and microstructure variations lead to white iron's hardness and wear resistance, contrasting with black iron's improved ductility and machinability.

Mechanical Properties Comparison

White iron exhibits higher hardness and wear resistance due to its cementite microstructure, making it ideal for abrasion-resistant applications. Black iron, specifically gray cast iron, contains graphite flakes that provide superior machinability and damping capacity but lower tensile strength and hardness. Mechanical properties vary significantly: white iron typically has a hardness of 600-700 HB, whereas black iron ranges from 150-300 HB, correlating with their distinct fracture toughness and brittleness levels.

Microstructure Analysis

White iron exhibits a microstructure dominated by cementite (Fe3C) forming a hard and brittle matrix, making it wear-resistant but prone to cracking under impact. Black iron, also known as gray iron, contains graphite flakes dispersed within a ferrite or pearlite matrix, which enhances its machinability and provides excellent vibration damping properties. Microstructure analysis using metallography reveals that the absence of free graphite in white iron leads to higher hardness, while the presence of graphite in black iron contributes to improved thermal conductivity and reduced brittleness.

Common Applications of White Iron

White iron is widely used in applications requiring exceptional wear resistance and hardness, such as in mining machinery, crushers, and grinding mills. Its high carbon content and cementite microstructure make it ideal for liners in cement plants, shot-blasting nozzles, and pipe elbows exposed to abrasive materials. Industries reliant on heavy-duty abrasion protection often prefer white iron due to its superior durability compared to black iron.

Common Applications of Black Iron

Black iron, primarily composed of uncoated steel, is widely used in the construction and plumbing industries due to its strength, durability, and corrosion resistance. Common applications include natural gas and water supply lines, fire sprinkler systems, and structural support components in buildings. Its affordability and ability to withstand high temperatures also make black iron a preferred choice for industrial piping and HVAC systems.

Wear Resistance: White Iron vs Black Iron

White iron exhibits superior wear resistance due to its high hardness and carbide content, making it ideal for applications involving abrasive materials. Black iron, characterized by its higher ductility and graphite flakes, offers lower wear resistance but better impact toughness. The microstructure difference between the brittle, hard white iron and the softer, more resilient black iron dictates their suitability for wear-intensive environments.

Corrosion Resistance Characteristics

White iron exhibits superior corrosion resistance due to its high hardness and dense microstructure, which inhibit chemical attack and wear. Black iron, commonly known as wrought iron, contains fibrous slag inclusions that provide some corrosion resistance but are less effective against aggressive environments. The chromium content in white iron alloys enhances their resistance to oxidation and acidic conditions, making them more durable in corrosive applications compared to black iron.

Cost and Availability

White iron is generally more expensive than black iron due to its complex alloy composition and specialized production process that enhances hardness and wear resistance. Black iron, also known as wrought iron or mild steel, is more widely available and cost-effective, making it a preferred choice for structural applications and general fabrication. The higher cost of white iron limits its use to niche applications requiring superior durability, while black iron dominates markets due to lower production costs and greater accessibility.

Choosing Between White Iron and Black Iron

Choosing between white iron and black iron depends on the specific application requirements such as wear resistance and machinability. White iron, characterized by its hard, brittle surface rich in cementite, excels in abrasion resistance and is ideal for heavy-duty wear parts. Black iron, also known as grey iron, offers better machinability and damping properties due to its graphite flakes, making it suitable for engine blocks and machinery where vibration absorption is essential.

White Iron vs Black Iron Infographic

materialdif.com

materialdif.com