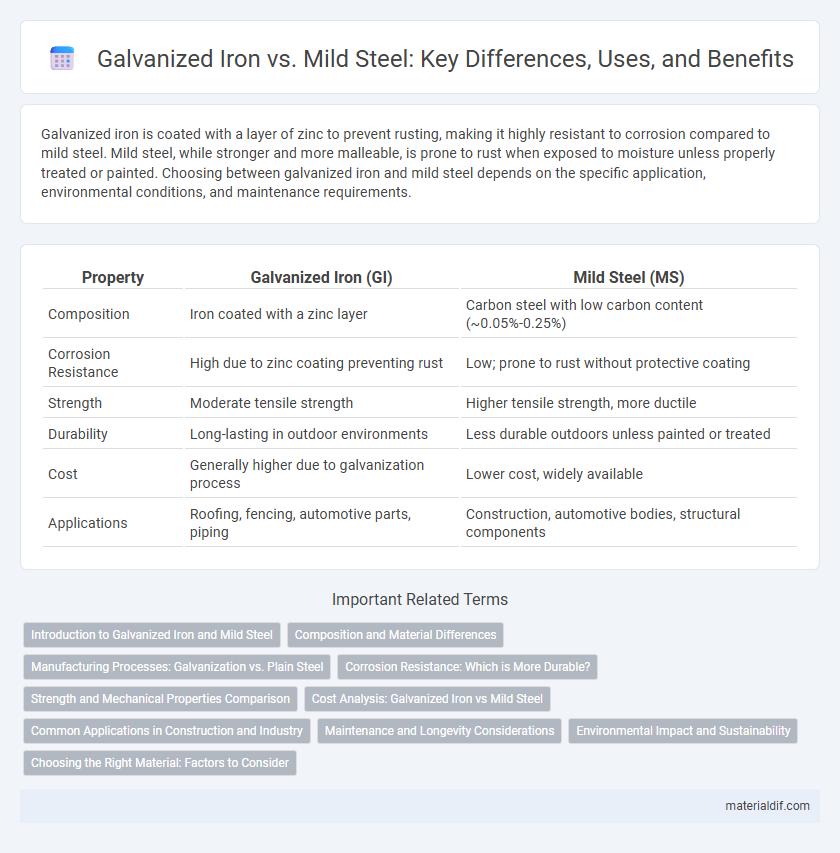

Galvanized iron is coated with a layer of zinc to prevent rusting, making it highly resistant to corrosion compared to mild steel. Mild steel, while stronger and more malleable, is prone to rust when exposed to moisture unless properly treated or painted. Choosing between galvanized iron and mild steel depends on the specific application, environmental conditions, and maintenance requirements.

Table of Comparison

| Property | Galvanized Iron (GI) | Mild Steel (MS) |

|---|---|---|

| Composition | Iron coated with a zinc layer | Carbon steel with low carbon content (~0.05%-0.25%) |

| Corrosion Resistance | High due to zinc coating preventing rust | Low; prone to rust without protective coating |

| Strength | Moderate tensile strength | Higher tensile strength, more ductile |

| Durability | Long-lasting in outdoor environments | Less durable outdoors unless painted or treated |

| Cost | Generally higher due to galvanization process | Lower cost, widely available |

| Applications | Roofing, fencing, automotive parts, piping | Construction, automotive bodies, structural components |

Introduction to Galvanized Iron and Mild Steel

Galvanized iron is steel coated with a protective layer of zinc to prevent rust and corrosion, making it ideal for outdoor and industrial applications. Mild steel, a low-carbon alloy, offers high strength and malleability but lacks the corrosion resistance of galvanized iron. The zinc coating on galvanized iron significantly enhances durability and lifespan compared to untreated mild steel.

Composition and Material Differences

Galvanized iron consists of a mild steel core coated with a layer of zinc, providing enhanced corrosion resistance compared to mild steel, which is primarily composed of iron with a small percentage of carbon. Mild steel, also known as low carbon steel, contains about 0.05% to 0.25% carbon, resulting in higher malleability and weldability but lower durability against rust. The zinc coating on galvanized iron acts as a sacrificial layer, protecting the underlying mild steel from oxidation and extending the material's lifespan in outdoor and humid environments.

Manufacturing Processes: Galvanization vs. Plain Steel

Galvanized iron undergoes a manufacturing process where mild steel is coated with a layer of zinc through hot-dip galvanization or electro-galvanization to enhance corrosion resistance. Mild steel, on the other hand, is produced through the basic oxygen steelmaking process or electric arc furnace method without any protective coating, leaving it more vulnerable to rust. The galvanization process significantly increases the durability and lifespan of the steel in harsh environments compared to plain mild steel.

Corrosion Resistance: Which is More Durable?

Galvanized iron features a protective zinc coating that significantly enhances its corrosion resistance, making it more durable in environments exposed to moisture and harsh weather conditions. Mild steel, lacking this protective layer, is prone to rust and degradation over time unless treated with paint or other protective measures. Therefore, galvanized iron outperforms mild steel in durability, especially in applications requiring resistance to corrosion.

Strength and Mechanical Properties Comparison

Galvanized iron exhibits enhanced corrosion resistance due to its zinc coating, while mild steel offers higher tensile strength and better ductility, making it suitable for structural applications requiring toughness. The mechanical properties of mild steel include a typical tensile strength of 400-550 MPa and elongation of approximately 20-25%, compared to galvanized iron's slightly lower strength but superior durability in corrosive environments. Selecting between galvanized iron and mild steel depends on the balance between mechanical strength and resistance to environmental degradation in specific use cases.

Cost Analysis: Galvanized Iron vs Mild Steel

Galvanized iron typically has a higher upfront cost compared to mild steel due to the protective zinc coating process that enhances corrosion resistance and longevity. Mild steel is less expensive initially but may incur higher maintenance and replacement costs over time because it is more prone to rust and deterioration in harsh environments. When considering long-term cost-effectiveness, galvanized iron often proves more economical despite its higher initial price, especially in outdoor or moisture-prone applications.

Common Applications in Construction and Industry

Galvanized iron, coated with zinc to prevent rust, is widely used in outdoor construction applications such as roofing, fencing, and ducting due to its corrosion resistance and durability. Mild steel, characterized by low carbon content, is favored in structural frameworks, automotive manufacturing, and machinery parts where strength and weldability are essential. Both materials play critical roles in industry, with galvanized iron excelling in environments exposed to moisture and mild steel providing robust support in load-bearing structures.

Maintenance and Longevity Considerations

Galvanized iron offers superior corrosion resistance due to its protective zinc coating, reducing maintenance needs and extending its lifespan in outdoor or humid environments. Mild steel requires regular painting or treatment to prevent rusting, increasing upkeep efforts and shortening its durability if neglected. Choosing galvanized iron can result in lower long-term maintenance costs and enhanced longevity compared to untreated mild steel.

Environmental Impact and Sustainability

Galvanized iron, coated with a layer of zinc to prevent rust, offers longer durability and reduces the frequency of replacement compared to mild steel, which corrodes more easily and requires additional protective coatings that may contain harmful chemicals. The zinc coating in galvanized iron is recyclable and extends the lifespan of the material, lowering the overall environmental footprint by minimizing waste and resource consumption. Mild steel production generates higher carbon emissions due to frequent maintenance and replacement cycles, making galvanized iron a more sustainable choice in construction and manufacturing applications.

Choosing the Right Material: Factors to Consider

When choosing between galvanized iron and mild steel, consider corrosion resistance, environmental exposure, and maintenance requirements. Galvanized iron, coated with a protective zinc layer, offers superior rust protection ideal for outdoor or humid environments, while mild steel provides greater strength and formability but needs protective coatings to prevent rust. Cost-effectiveness and application-specific durability also influence material selection for construction, fabrication, or industrial use.

Galvanized Iron vs Mild Steel Infographic

materialdif.com

materialdif.com