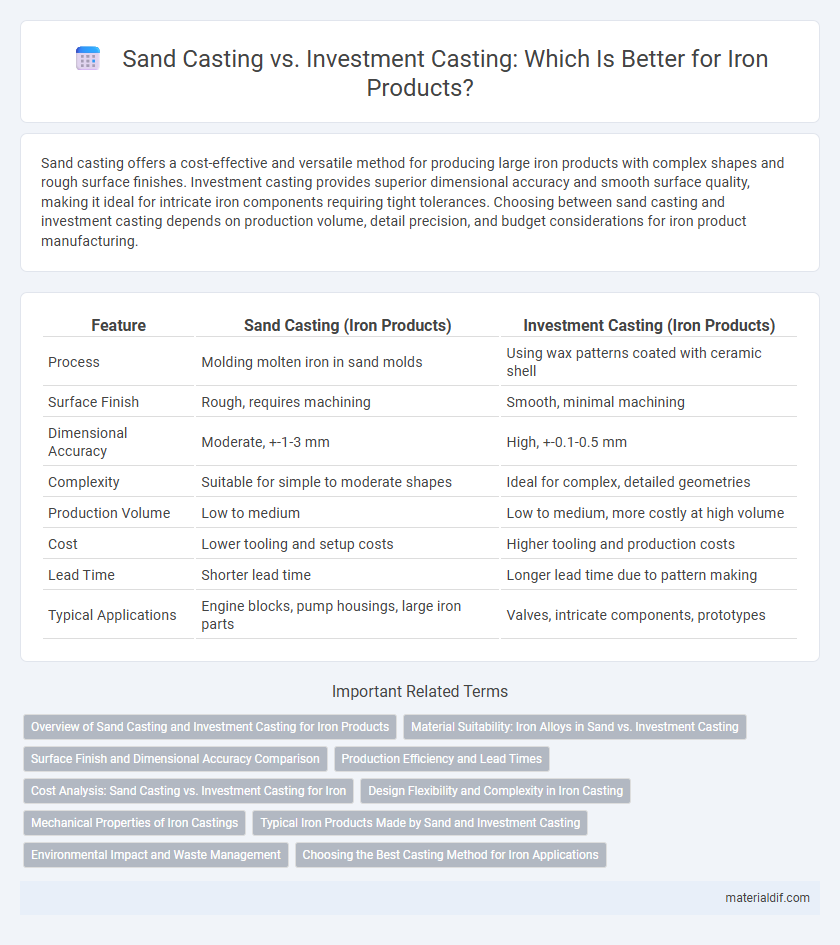

Sand casting offers a cost-effective and versatile method for producing large iron products with complex shapes and rough surface finishes. Investment casting provides superior dimensional accuracy and smooth surface quality, making it ideal for intricate iron components requiring tight tolerances. Choosing between sand casting and investment casting depends on production volume, detail precision, and budget considerations for iron product manufacturing.

Table of Comparison

| Feature | Sand Casting (Iron Products) | Investment Casting (Iron Products) |

|---|---|---|

| Process | Molding molten iron in sand molds | Using wax patterns coated with ceramic shell |

| Surface Finish | Rough, requires machining | Smooth, minimal machining |

| Dimensional Accuracy | Moderate, +-1-3 mm | High, +-0.1-0.5 mm |

| Complexity | Suitable for simple to moderate shapes | Ideal for complex, detailed geometries |

| Production Volume | Low to medium | Low to medium, more costly at high volume |

| Cost | Lower tooling and setup costs | Higher tooling and production costs |

| Lead Time | Shorter lead time | Longer lead time due to pattern making |

| Typical Applications | Engine blocks, pump housings, large iron parts | Valves, intricate components, prototypes |

Overview of Sand Casting and Investment Casting for Iron Products

Sand casting involves creating a mold from a sand mixture that captures the iron's shape, allowing for the production of large, complex iron components with moderate dimensional accuracy and surface finish. Investment casting uses a wax pattern coated with ceramic material to form a detailed mold, producing iron parts with superior surface quality and intricate geometries suitable for precision applications. Both methods serve distinct manufacturing needs, with sand casting favored for cost-effective, large-scale iron parts and investment casting chosen for high-precision, detailed iron components.

Material Suitability: Iron Alloys in Sand vs. Investment Casting

Iron alloys in sand casting exhibit excellent suitability for producing large, heavy, and complex shapes due to their high melting points and good fluidity, accommodating varied carbon content ranges common in cast irons. Investment casting offers superior dimensional accuracy and surface finish for iron products, effectively handling intricate geometries with iron alloys that benefit from tighter control over alloy composition and reduced porosity. Both methods require consideration of iron alloy properties such as shrinkage, fluidity, and thermal conductivity to optimize casting performance and final product quality.

Surface Finish and Dimensional Accuracy Comparison

Investment casting offers superior surface finish and higher dimensional accuracy than sand casting for iron products, producing smoother surfaces with minimal machining required. Sand casting typically results in rougher surfaces due to the granular nature of sand molds, necessitating additional finishing processes to achieve desired smoothness. Dimensional tolerances in investment casting are tighter, often within +-0.005 inches, compared to sand casting tolerances which can be +-0.020 inches or more, making investment casting ideal for intricate iron components.

Production Efficiency and Lead Times

Sand casting offers higher production efficiency for large, simple iron products due to its lower cost and faster mold preparation, making it suitable for high-volume runs. Investment casting provides superior precision and surface finish for complex iron components but involves longer lead times given the multi-step wax pattern creation and ceramic shell processes. For iron parts requiring tight tolerances and intricate details, investment casting balances quality against extended production cycles, whereas sand casting excels in speed and cost-effectiveness for bulk manufacturing.

Cost Analysis: Sand Casting vs. Investment Casting for Iron

Sand casting generally offers lower initial tooling costs and is more cost-effective for producing large, simple iron parts in high volumes. Investment casting involves higher upfront expenses due to intricate mold creation but delivers superior precision and surface finish, reducing post-processing costs for complex iron components. Cost efficiency depends on production scale, part complexity, and required dimensional accuracy within iron manufacturing.

Design Flexibility and Complexity in Iron Casting

Sand casting offers greater design flexibility for iron products due to its ability to produce large and complex shapes with varying wall thicknesses. Investment casting excels in achieving intricate details and finer surface finishes, making it ideal for complex and precision iron components. Both methods cater to different complexity requirements, with investment casting favored for high-precision designs and sand casting preferred for larger, less intricate iron parts.

Mechanical Properties of Iron Castings

Sand casting iron products typically exhibit coarser grain structures, resulting in moderate tensile strength and ductility ideal for larger, less intricate components. Investment casting produces finer microstructures that enhance mechanical properties, including higher strength, improved hardness, and better fatigue resistance, making it suitable for precision, high-performance iron parts. Mechanical properties of iron castings depend significantly on casting method, mold material, and cooling rates which influence microstructure and defect formation.

Typical Iron Products Made by Sand and Investment Casting

Sand casting typically produces large iron components such as engine blocks, pump housings, and valve bodies due to its cost-effectiveness and ability to handle complex geometries with thicker sections. Investment casting excels in manufacturing intricate iron products like gears, turbine blades, and decorative ironwork that require fine detail and superior surface finish. Both methods serve distinct industries, with sand casting favored for heavy-duty applications and investment casting preferred for precision and aesthetic iron parts.

Environmental Impact and Waste Management

Sand casting of iron generates significant silica sand waste that requires careful disposal to prevent environmental contamination, while investment casting produces less solid waste but uses ceramic molds that demand energy-intensive recycling processes. The sand from sand casting can often be reclaimed and reused, reducing raw material consumption, whereas investment casting's ceramic shell waste is more challenging to recycle, impacting landfill volumes. Both methods necessitate efficient waste management systems to mitigate their carbon footprint and minimize hazardous emissions associated with iron casting operations.

Choosing the Best Casting Method for Iron Applications

Sand casting offers cost-effective production for large iron components with complex geometries and moderate surface finish requirements. Investment casting provides superior dimensional accuracy and smoother surface finishes ideal for intricate iron parts and high-precision applications. Selecting the best casting method depends on balancing part complexity, surface quality needs, production volume, and overall cost efficiency in iron manufacturing.

Sand Casting vs Investment Casting (Iron Products) Infographic

materialdif.com

materialdif.com