Iron casting involves pouring molten iron into molds to create complex shapes with intricate details, making it ideal for producing large quantities of identical parts. Iron forging, on the other hand, involves shaping heated iron using compressive forces, resulting in components with superior strength and durability due to refined grain structure. Each method serves specific industrial applications, with casting favored for precision and cost-efficiency, while forging is chosen for performance-critical parts.

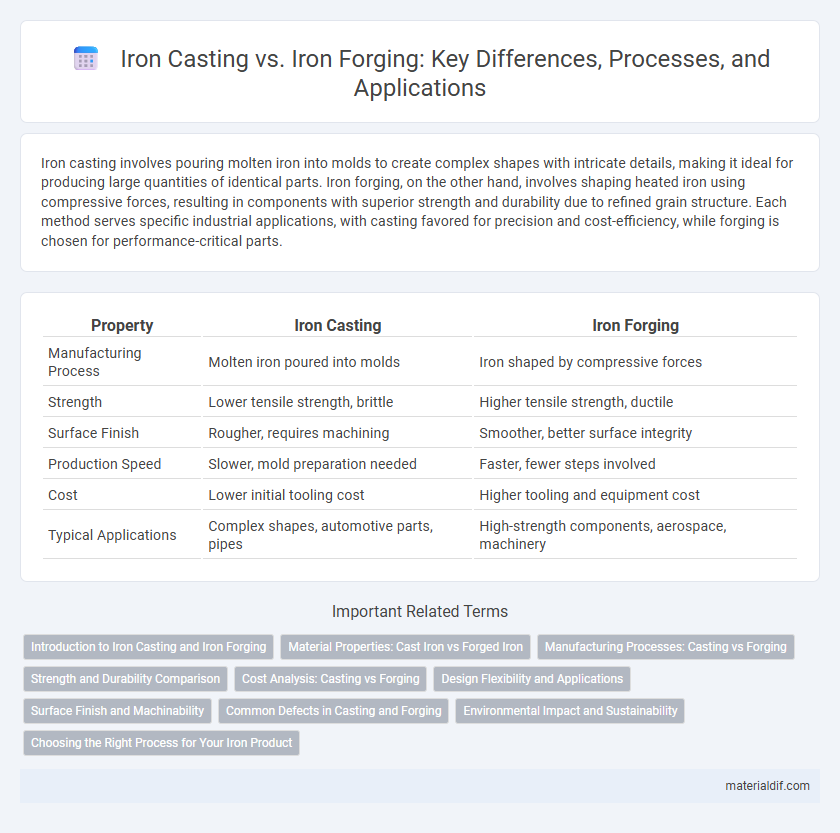

Table of Comparison

| Property | Iron Casting | Iron Forging |

|---|---|---|

| Manufacturing Process | Molten iron poured into molds | Iron shaped by compressive forces |

| Strength | Lower tensile strength, brittle | Higher tensile strength, ductile |

| Surface Finish | Rougher, requires machining | Smoother, better surface integrity |

| Production Speed | Slower, mold preparation needed | Faster, fewer steps involved |

| Cost | Lower initial tooling cost | Higher tooling and equipment cost |

| Typical Applications | Complex shapes, automotive parts, pipes | High-strength components, aerospace, machinery |

Introduction to Iron Casting and Iron Forging

Iron casting involves melting iron and pouring it into molds to create complex shapes with high dimensional accuracy, making it ideal for large and intricate components. Iron forging, on the other hand, shapes iron through localized compressive forces, enhancing metal grain structure and resulting in superior strength and toughness. Both processes are fundamental in manufacturing but serve distinct purposes depending on the desired mechanical properties and component geometry.

Material Properties: Cast Iron vs Forged Iron

Cast iron exhibits high compressive strength and excellent wear resistance due to its carbon-rich microstructure, but it is brittle and prone to cracking under tensile stress. Forged iron, characterized by a refined grain structure from plastic deformation, offers superior tensile strength, toughness, and impact resistance compared to cast iron. The material properties of forged iron make it ideal for applications demanding durability and resistance to dynamic loads, whereas cast iron suits scenarios where rigidity and hardness are prioritized.

Manufacturing Processes: Casting vs Forging

Iron casting involves pouring molten iron into molds to create complex shapes with high dimensional accuracy, ideal for producing intricate components in large quantities. Iron forging compresses heated iron using high pressure to refine its grain structure, resulting in superior mechanical strength and fatigue resistance for critical load-bearing parts. The choice between casting and forging in manufacturing depends on factors like component geometry, mechanical property requirements, and production volume.

Strength and Durability Comparison

Iron forging produces components with superior strength and durability due to the metal's grain structure being aligned and compressed during the process, enhancing toughness and resistance to fatigue. In contrast, iron casting involves melting and pouring molten iron into molds, resulting in a more brittle microstructure with potential porosity, which reduces impact strength and increases susceptibility to cracking. Forged iron parts exhibit higher tensile strength and improved fatigue life compared to cast iron, making forging more suitable for high-stress applications requiring long-term durability.

Cost Analysis: Casting vs Forging

Iron casting generally incurs lower initial tooling and production costs due to its ability to produce complex shapes with minimal machining, making it cost-effective for large production runs. Iron forging involves higher labor and equipment expenses, but yields superior mechanical properties and durability, which can reduce long-term maintenance costs. Cost analysis must consider production volume, material waste, and application-specific performance requirements when choosing between casting and forging.

Design Flexibility and Applications

Iron casting offers superior design flexibility, allowing complex shapes and intricate details that are difficult to achieve with forging processes. Forging produces components with enhanced mechanical properties due to grain refinement, ideal for high-stress applications like automotive and aerospace parts. Casting suits applications requiring detailed geometries and large volumes, whereas forging excels in producing durable parts subjected to heavy loads and dynamic forces.

Surface Finish and Machinability

Iron casting produces a rougher surface finish compared to iron forging, which results in a smoother and more uniform texture ideal for aesthetic applications. The cast iron's irregular surface often requires extensive machining to achieve desired tolerances, while forged iron exhibits superior machinability due to its refined grain structure and reduced porosity. Surface finish and machinability differences between casting and forging significantly impact the post-processing costs and performance of iron components.

Common Defects in Casting and Forging

Common defects in iron casting include porosity, shrinkage cavities, and cold shuts, resulting from improper mold filling or cooling rates. Forging defects primarily involve laps, cracks, and scale inclusions caused by inadequate deformation or overheating during the process. Addressing these issues enhances the mechanical properties and structural integrity of iron components.

Environmental Impact and Sustainability

Iron casting generates higher carbon emissions due to energy-intensive melting processes, whereas iron forging uses mechanical deformation, which typically consumes less energy. The recyclability of cast iron promotes sustainability, but forging's ability to produce stronger, longer-lasting components reduces the need for frequent replacements and resource consumption. Overall, forging offers a more sustainable approach by minimizing waste and lowering the environmental footprint compared to traditional casting methods.

Choosing the Right Process for Your Iron Product

Selecting between iron casting and iron forging depends on the desired product characteristics and application requirements. Casting offers complex shapes with intricate details and is cost-effective for large production runs, whereas forging provides superior strength and durability due to the metal's refined grain structure. Evaluating factors such as mechanical strength, production volume, and design complexity ensures choosing the optimal method for high-performance iron components.

Iron Casting vs Iron Forging Infographic

materialdif.com

materialdif.com