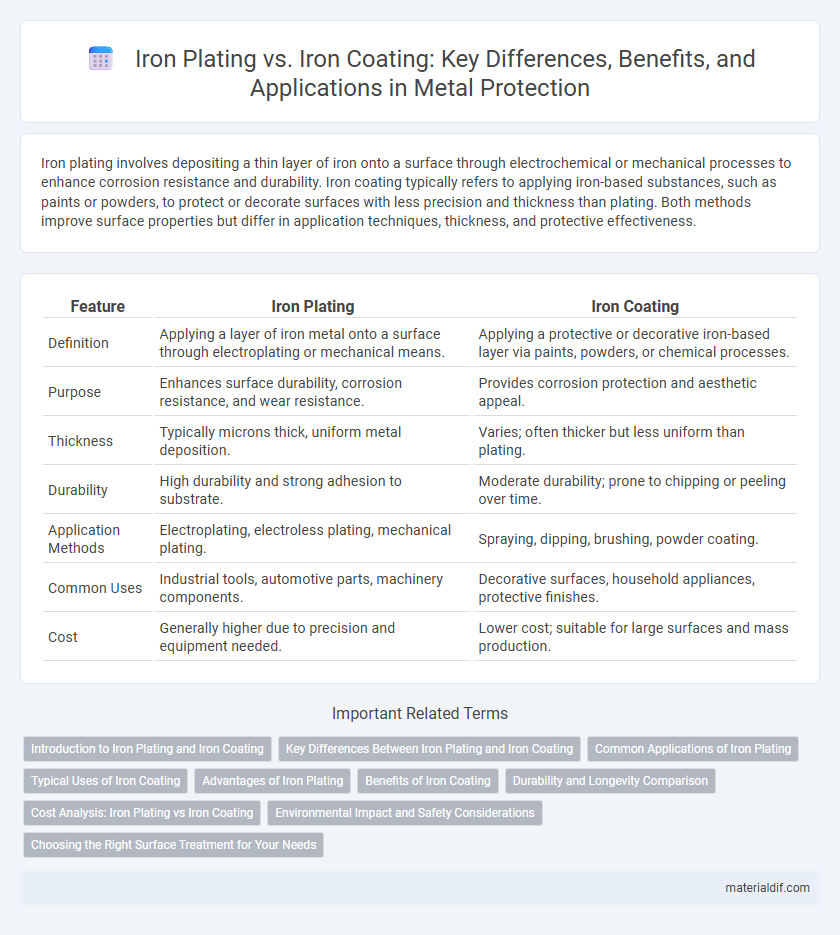

Iron plating involves depositing a thin layer of iron onto a surface through electrochemical or mechanical processes to enhance corrosion resistance and durability. Iron coating typically refers to applying iron-based substances, such as paints or powders, to protect or decorate surfaces with less precision and thickness than plating. Both methods improve surface properties but differ in application techniques, thickness, and protective effectiveness.

Table of Comparison

| Feature | Iron Plating | Iron Coating |

|---|---|---|

| Definition | Applying a layer of iron metal onto a surface through electroplating or mechanical means. | Applying a protective or decorative iron-based layer via paints, powders, or chemical processes. |

| Purpose | Enhances surface durability, corrosion resistance, and wear resistance. | Provides corrosion protection and aesthetic appeal. |

| Thickness | Typically microns thick, uniform metal deposition. | Varies; often thicker but less uniform than plating. |

| Durability | High durability and strong adhesion to substrate. | Moderate durability; prone to chipping or peeling over time. |

| Application Methods | Electroplating, electroless plating, mechanical plating. | Spraying, dipping, brushing, powder coating. |

| Common Uses | Industrial tools, automotive parts, machinery components. | Decorative surfaces, household appliances, protective finishes. |

| Cost | Generally higher due to precision and equipment needed. | Lower cost; suitable for large surfaces and mass production. |

Introduction to Iron Plating and Iron Coating

Iron plating involves depositing a thin layer of iron onto a surface through electrochemical processes to enhance corrosion resistance and wear durability. Iron coating, typically applied as a powder or liquid, creates a protective iron-rich barrier that improves surface hardness and oxidation resistance. Both techniques are critical in industrial applications requiring robust metal protection and performance.

Key Differences Between Iron Plating and Iron Coating

Iron plating involves depositing a thin layer of iron onto a surface through electrochemical processes, enhancing corrosion resistance and wear protection with precise thickness control. Iron coating typically refers to applying a thicker, often less uniform iron layer using methods such as spray or dip coating, primarily aimed at surface protection and aesthetic improvement. Key differences lie in the deposition technique, layer uniformity, thickness control, and the resulting durability and surface quality.

Common Applications of Iron Plating

Iron plating is widely used in industries such as automotive manufacturing, electronics, and construction due to its ability to enhance surface hardness and corrosion resistance on steel and other metal components. Common applications include protective layers on machinery parts, decorative finishes on appliances, and improving electrical conductivity in electronic connectors. This method offers durability and cost-effectiveness compared to iron coating, which is typically a thinner, less robust layer mainly used for aesthetic purposes.

Typical Uses of Iron Coating

Iron coating is typically used to enhance surface resistance against corrosion and wear, making it ideal for automotive parts, construction materials, and machinery exposed to harsh environments. It provides a protective barrier that extends the lifespan of metal components without significantly altering their dimensional tolerances. Common applications include tools, industrial equipment, and infrastructure elements requiring durable, corrosion-resistant finishes.

Advantages of Iron Plating

Iron plating offers superior corrosion resistance by creating a thick, durable layer that protects the underlying metal from oxidation and wear. It enhances mechanical properties such as hardness and abrasion resistance, extending the lifespan of industrial components. This method provides a uniform, smooth finish that improves both aesthetic appeal and functional performance compared to traditional iron coating.

Benefits of Iron Coating

Iron coating provides superior corrosion resistance compared to iron plating by forming a durable, uniform barrier that prevents rust and extends the lifespan of metal surfaces. This method enhances adhesion and reduces the risk of peeling or flaking, ensuring long-term protection under harsh environmental conditions. Iron coating also improves wear resistance, making it ideal for industrial applications requiring durable and maintenance-free metal components.

Durability and Longevity Comparison

Iron plating provides a thicker, more uniform layer of metal that significantly enhances surface durability and resistance to corrosion compared to iron coating. The electroplated layer created during iron plating offers superior adhesion and longevity, making it ideal for industrial applications requiring prolonged wear protection. In contrast, iron coating, often applied as a thinner chemical or paint layer, typically exhibits lower durability and may require more frequent maintenance to prevent degradation.

Cost Analysis: Iron Plating vs Iron Coating

Iron plating typically incurs higher initial costs due to the use of specialized electrochemical processes and expensive materials such as pure iron anodes, whereas iron coating involves more affordable application methods like spray or brush techniques using iron-based paints or powders. Maintenance expenses for iron plating are generally lower because of its superior durability and corrosion resistance, reducing the frequency of reapplication compared to iron coating, which may require more frequent upkeep in harsh environments. Total cost analysis must consider both upfront investment and long-term maintenance, where iron plating tends to be more cost-effective for industrial applications with high wear, while iron coating is suitable for budget-conscious projects with moderate protection needs.

Environmental Impact and Safety Considerations

Iron plating involves electroplating iron onto a surface, often using hazardous chemicals like cyanides and heavy metals, increasing environmental pollution risks and requiring strict waste management protocols. Iron coating methods, such as powder coating or painting with iron-based pigments, tend to have lower toxicity and reduce harmful byproducts, improving safety for workers and minimizing ecological damage. Both processes necessitate careful handling, but iron coating generally offers a more environmentally sustainable and less hazardous alternative.

Choosing the Right Surface Treatment for Your Needs

Iron plating involves depositing a layer of iron onto a surface through electroplating, providing enhanced corrosion resistance and improved durability for industrial parts. Iron coating, often applied via powder or spray methods, offers flexible thickness control and is ideal for decorative or light protection purposes. Selecting the appropriate surface treatment depends on factors like environmental exposure, mechanical stress, and desired appearance, with plating favored for heavy-duty applications and coating suited for aesthetic or moderate protection requirements.

Iron Plating vs Iron Coating Infographic

materialdif.com

materialdif.com