Ferrous iron contains significant amounts of iron and is magnetic, making it ideal for construction and automotive industries due to its strength and durability. Non-ferrous alloys, which exclude iron, offer superior corrosion resistance, electrical conductivity, and lightweight properties, commonly used in aerospace and electrical applications. Understanding the differences between ferrous and non-ferrous alloys is essential for selecting the right material based on mechanical properties and environmental factors.

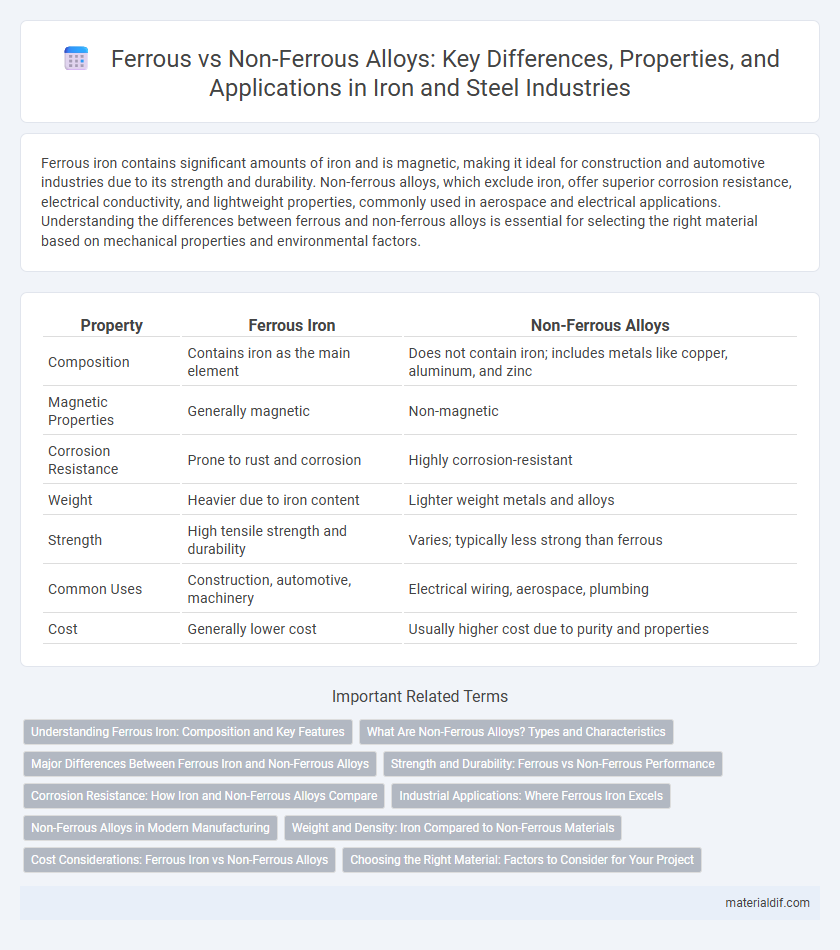

Table of Comparison

| Property | Ferrous Iron | Non-Ferrous Alloys |

|---|---|---|

| Composition | Contains iron as the main element | Does not contain iron; includes metals like copper, aluminum, and zinc |

| Magnetic Properties | Generally magnetic | Non-magnetic |

| Corrosion Resistance | Prone to rust and corrosion | Highly corrosion-resistant |

| Weight | Heavier due to iron content | Lighter weight metals and alloys |

| Strength | High tensile strength and durability | Varies; typically less strong than ferrous |

| Common Uses | Construction, automotive, machinery | Electrical wiring, aerospace, plumbing |

| Cost | Generally lower cost | Usually higher cost due to purity and properties |

Understanding Ferrous Iron: Composition and Key Features

Ferrous iron primarily consists of iron with small amounts of carbon and other elements, forming alloys such as carbon steel and cast iron known for their magnetic properties and high tensile strength. It contains significant iron content, typically over 50%, which distinguishes it from non-ferrous alloys that lack iron. Key features include excellent weldability, durability, and susceptibility to corrosion without protective coatings.

What Are Non-Ferrous Alloys? Types and Characteristics

Non-ferrous alloys are metal combinations that do not contain significant amounts of iron, offering enhanced resistance to corrosion, lightweight properties, and superior conductivity compared to ferrous metals. Common types include aluminum alloys, known for their strength-to-weight ratio; copper alloys, which provide excellent electrical and thermal conductivity; and titanium alloys, valued for high strength and corrosion resistance in aerospace applications. These characteristics make non-ferrous alloys ideal for industries requiring materials that resist rust and maintain performance under diverse environmental conditions.

Major Differences Between Ferrous Iron and Non-Ferrous Alloys

Ferrous iron alloys primarily contain iron and are magnetic with high tensile strength, making them ideal for construction and manufacturing applications. Non-ferrous alloys, such as aluminum, copper, and titanium, do not contain significant iron content, offering superior corrosion resistance, lighter weight, and enhanced electrical conductivity. The major differences lie in magnetic properties, corrosion resistance, density, and typical industrial applications.

Strength and Durability: Ferrous vs Non-Ferrous Performance

Ferrous alloys, primarily composed of iron and carbon, excel in strength and durability, making them ideal for structural applications and heavy-duty machinery due to their high tensile strength and resistance to wear. Non-ferrous alloys, such as aluminum and copper-based metals, offer superior corrosion resistance and lighter weight, which enhances performance in environments where rust and oxidation are concerns. While ferrous metals dominate in strength-intensive roles, non-ferrous alloys provide durability advantages in specialized applications requiring reduced weight and enhanced corrosion endurance.

Corrosion Resistance: How Iron and Non-Ferrous Alloys Compare

Ferrous iron, containing a significant amount of iron, is prone to rust and corrosion when exposed to moisture and oxygen, making it less corrosion-resistant than non-ferrous alloys like aluminum, copper, and zinc which naturally resist oxidation. Non-ferrous alloys are often preferred in environments where corrosion resistance is critical, such as in marine applications, electrical wiring, and chemical processing equipment. The presence of alloys like chromium in stainless steel enhances ferrous metal's corrosion resistance, but generally, non-ferrous metals offer superior durability against corrosive elements.

Industrial Applications: Where Ferrous Iron Excels

Ferrous iron alloys dominate industrial applications due to their superior strength, durability, and magnetic properties, making them ideal for construction, automotive, and heavy machinery. Steel, a primary ferrous alloy, is extensively used for structural frameworks, pipelines, and manufacturing tools, benefiting from its cost-effectiveness and recyclability. Contrastingly, non-ferrous alloys excel in corrosion resistance and electrical conductivity but often lack the mechanical robustness required for heavy-load industrial environments where ferrous metals prevail.

Non-Ferrous Alloys in Modern Manufacturing

Non-ferrous alloys, such as aluminum, copper, and titanium, play a critical role in modern manufacturing due to their lightweight, corrosion resistance, and excellent conductivity. These alloys are essential in aerospace, automotive, and electronics industries where durability and performance are paramount. Their ability to maintain strength at high temperatures makes non-ferrous materials superior to ferrous iron alloys in specific high-tech applications.

Weight and Density: Iron Compared to Non-Ferrous Materials

Ferrous iron alloys typically exhibit higher density values, averaging around 7.8 g/cm3, compared to non-ferrous alloys such as aluminum (2.7 g/cm3) and magnesium (1.7 g/cm3), making ferrous materials significantly heavier. The increased weight of ferrous alloys influences their use in structural and heavy-duty applications where strength and durability are essential. Non-ferrous alloys offer advantages in weight-sensitive industries due to their lower density, providing improved corrosion resistance and lighter component design.

Cost Considerations: Ferrous Iron vs Non-Ferrous Alloys

Ferrous iron alloys typically offer lower material and production costs due to the abundance of iron and established manufacturing processes. Non-ferrous alloys, including aluminum, copper, and titanium, incur higher costs driven by raw material scarcity and energy-intensive extraction methods. Cost considerations favor ferrous options for large-scale, budget-sensitive applications, while non-ferrous alloys justify higher expenses through superior corrosion resistance and lightweight properties.

Choosing the Right Material: Factors to Consider for Your Project

Choosing the right material for your project involves evaluating the mechanical properties, corrosion resistance, and thermal conductivity of ferrous iron versus non-ferrous alloys. Ferrous iron, containing iron as the principal element, offers superior strength and magnetic properties, making it ideal for construction and heavy machinery. Non-ferrous alloys, such as aluminum, copper, and titanium-based metals, provide excellent corrosion resistance and lighter weight, crucial for aerospace, electrical, and marine applications.

Ferrous Iron vs Non-Ferrous Alloys Infographic

materialdif.com

materialdif.com