Painted iron offers enhanced protection against rust and corrosion compared to bare iron, making it ideal for outdoor and humid environments. Bare iron, while more susceptible to oxidation, provides a raw, industrial aesthetic favored in rustic and vintage designs. Choosing between painted and bare iron depends on balancing durability needs with desired visual appeal.

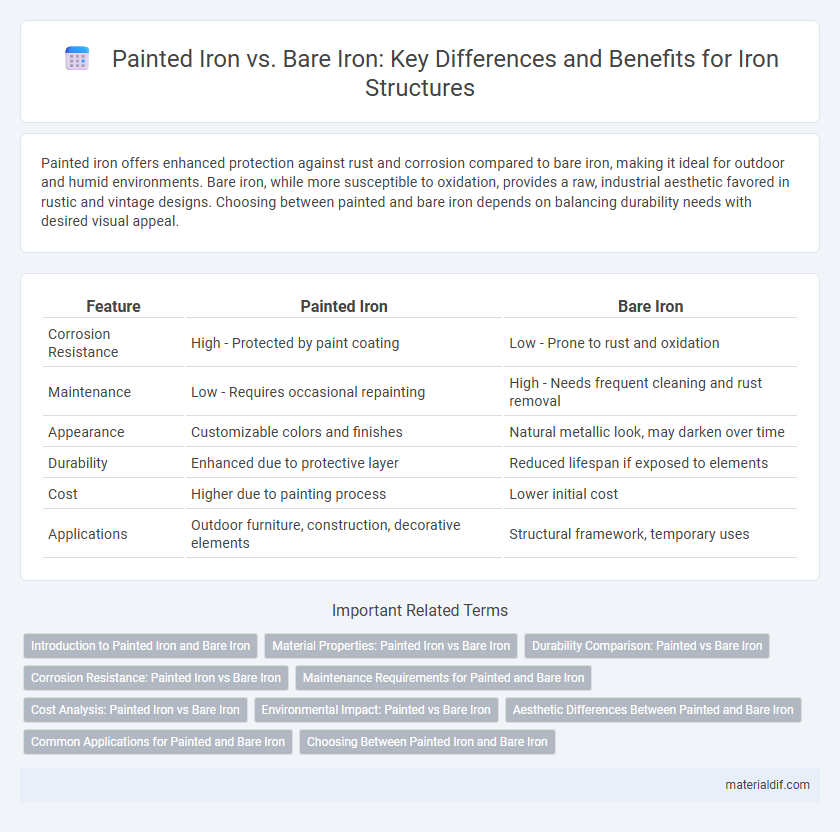

Table of Comparison

| Feature | Painted Iron | Bare Iron |

|---|---|---|

| Corrosion Resistance | High - Protected by paint coating | Low - Prone to rust and oxidation |

| Maintenance | Low - Requires occasional repainting | High - Needs frequent cleaning and rust removal |

| Appearance | Customizable colors and finishes | Natural metallic look, may darken over time |

| Durability | Enhanced due to protective layer | Reduced lifespan if exposed to elements |

| Cost | Higher due to painting process | Lower initial cost |

| Applications | Outdoor furniture, construction, decorative elements | Structural framework, temporary uses |

Introduction to Painted Iron and Bare Iron

Painted iron features a protective coating that enhances durability and prevents rust, making it ideal for outdoor and industrial applications. Bare iron lacks a protective layer, leaving it vulnerable to corrosion and requiring regular maintenance to maintain its integrity. Choosing between painted and bare iron depends on the intended use, environmental exposure, and maintenance capabilities.

Material Properties: Painted Iron vs Bare Iron

Painted iron offers enhanced corrosion resistance compared to bare iron due to the protective barrier provided by the paint coating, which prevents oxidation and rust formation. Bare iron is more susceptible to environmental factors such as moisture and air, leading to quicker degradation and structural weakness over time. The paint layer also improves aesthetic durability and reduces maintenance frequency by shielding the iron surface from scratches and chemical exposure.

Durability Comparison: Painted vs Bare Iron

Painted iron offers enhanced durability by providing a protective layer against rust, corrosion, and environmental damage, significantly extending its lifespan compared to bare iron. Bare iron, without any coating, is prone to oxidation and deteriorates faster when exposed to moisture and air, resulting in reduced structural integrity over time. Choosing painted iron is essential for applications requiring long-term strength and resistance to weathering.

Corrosion Resistance: Painted Iron vs Bare Iron

Painted iron offers significantly enhanced corrosion resistance compared to bare iron by creating a protective barrier that prevents moisture and oxygen from reaching the metal surface, which inhibits rust formation. Bare iron, lacking this coating, is highly susceptible to oxidation, leading to rapid corrosion and structural degradation over time. The durability and lifespan of iron structures are greatly improved when using painted iron, especially in environments exposed to humidity and corrosive elements.

Maintenance Requirements for Painted and Bare Iron

Painted iron requires regular inspection and touch-ups to prevent paint peeling and rust formation, ensuring prolonged protection against moisture and corrosion. Bare iron demands frequent cleaning and application of rust inhibitors or protective coatings to avoid oxidation and structural damage. Proper maintenance of both types extends lifespan, with painted iron providing a more straightforward barrier against environmental elements.

Cost Analysis: Painted Iron vs Bare Iron

Painted iron incurs higher initial costs due to expenses for primers, paints, and labor-intensive application processes, but it offers long-term savings by significantly reducing corrosion-related maintenance and replacement. Bare iron has lower upfront costs but frequently demands costly repairs and treatments to address rust and degradation over time. Evaluating total lifecycle costs reveals painted iron as a more economical choice in environments prone to moisture and oxidation.

Environmental Impact: Painted vs Bare Iron

Painted iron reduces corrosion and extends the lifespan of the material, minimizing the need for frequent replacements and thereby lowering overall environmental impact. Bare iron, exposed to moisture and oxygen, oxidizes rapidly, leading to rust that weakens the metal and necessitates more frequent resource extraction and manufacturing processes. Protective coatings on painted iron decrease maintenance frequency, reducing energy consumption and waste generation associated with metal production and disposal.

Aesthetic Differences Between Painted and Bare Iron

Painted iron offers a smooth, vibrant surface that resists rust and enhances visual appeal through customizable colors and finishes, making it ideal for decorative applications. Bare iron displays a raw, industrial aesthetic characterized by its natural metallic texture and the development of rust patina over time, which can add a rustic charm but requires maintenance to prevent corrosion. Selecting between painted and bare iron largely depends on desired appearance, durability, and environmental exposure.

Common Applications for Painted and Bare Iron

Painted iron is commonly used in outdoor furniture, railings, and automotive parts due to its enhanced corrosion resistance and aesthetic appeal. Bare iron finds frequent application in construction frameworks, machinery components, and industrial equipment where structural strength is prioritized over surface finish. Both forms serve crucial roles in manufacturing and engineering, selected based on environmental exposure and functional requirements.

Choosing Between Painted Iron and Bare Iron

Choosing between painted iron and bare iron depends on the intended use and environment exposure; painted iron offers enhanced corrosion resistance and aesthetic appeal due to its protective coating, making it ideal for outdoor or humid conditions. Bare iron requires regular maintenance to prevent rust and is better suited for indoor applications where moisture is minimal. Cost considerations favor bare iron initially, but painted iron often reduces long-term maintenance expenses and extends the material's lifespan.

Painted Iron vs Bare Iron Infographic

materialdif.com

materialdif.com