Forged iron is shaped by heating and hammering, resulting in a dense, strong structure ideal for tools and decorative pieces. Rolled iron, produced by passing heated iron through rollers, offers uniform thickness and enhanced surface finish, making it suitable for construction and industrial applications. The choice between forged and rolled iron depends on the required strength, flexibility, and application.

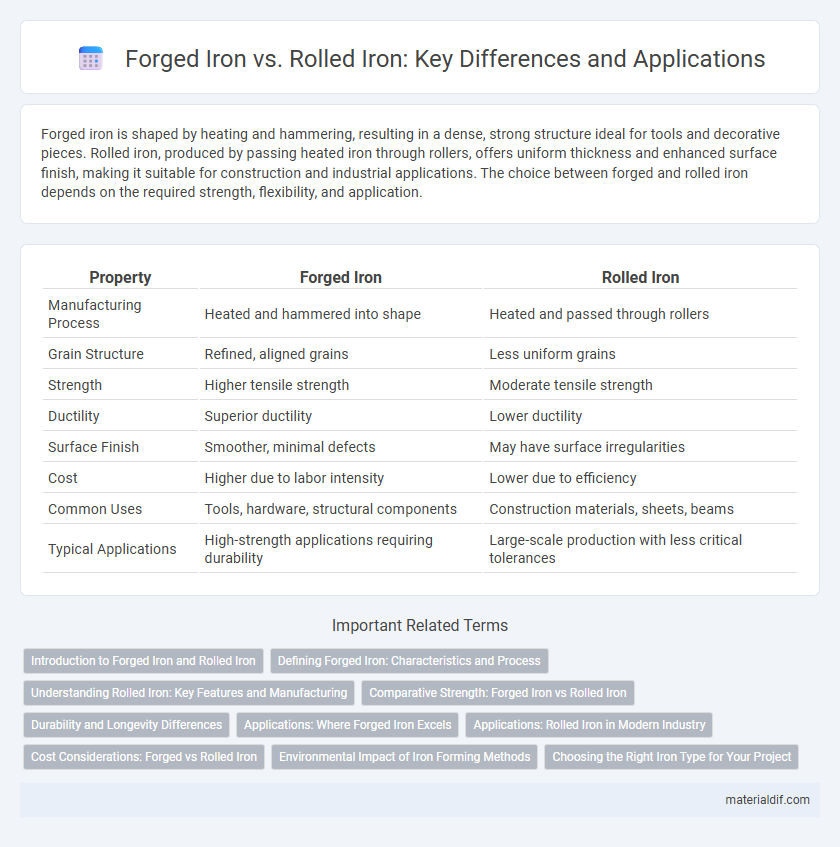

Table of Comparison

| Property | Forged Iron | Rolled Iron |

|---|---|---|

| Manufacturing Process | Heated and hammered into shape | Heated and passed through rollers |

| Grain Structure | Refined, aligned grains | Less uniform grains |

| Strength | Higher tensile strength | Moderate tensile strength |

| Ductility | Superior ductility | Lower ductility |

| Surface Finish | Smoother, minimal defects | May have surface irregularities |

| Cost | Higher due to labor intensity | Lower due to efficiency |

| Common Uses | Tools, hardware, structural components | Construction materials, sheets, beams |

| Typical Applications | High-strength applications requiring durability | Large-scale production with less critical tolerances |

Introduction to Forged Iron and Rolled Iron

Forged iron is created by heating iron and shaping it through hammering or pressing, resulting in a material known for its superior strength and durability due to the compact grain structure. Rolled iron, on the other hand, is produced by passing heated iron through rollers to achieve desired thickness and surface finish, offering consistency and uniform mechanical properties. Both processes influence the microstructure and mechanical behavior, with forged iron typically excelling in applications requiring toughness and fatigue resistance, while rolled iron is favored for mass production with precise dimensional control.

Defining Forged Iron: Characteristics and Process

Forged iron is characterized by its high strength and durability, achieved through the process of heating iron until malleable and then shaping it under pressure using hammers or presses. This manufacturing technique aligns the metal's grain structure, enhancing its toughness and resistance to wear compared to rolled iron. The controlled deformation in forging creates fewer internal voids, resulting in superior mechanical properties essential for heavy-duty applications.

Understanding Rolled Iron: Key Features and Manufacturing

Rolled iron is produced by passing heated iron through rollers to achieve a uniform thickness and smooth surface, enhancing its mechanical properties and structural integrity. This process imparts greater strength and ductility compared to forged iron, making rolled iron ideal for applications requiring consistent dimensions and high tensile strength. Key features of rolled iron include fine grain structure, improved weldability, and resistance to deformation, resulting from controlled cooling and deformation during the rolling process.

Comparative Strength: Forged Iron vs Rolled Iron

Forged iron exhibits higher tensile strength and superior structural integrity compared to rolled iron due to the grain alignment achieved during the forging process. Rolled iron, while offering uniform thickness and enhanced surface finish, generally has lower mechanical strength because of its microstructural differences. The dense grain structure in forged iron contributes to greater resistance against fatigue and impact, making it the preferred choice for high-strength applications.

Durability and Longevity Differences

Forged iron exhibits superior durability due to its denser microstructure formed through hammering and shaping at high temperatures, resulting in enhanced resistance to wear and mechanical stress. Rolled iron, produced by passing heated iron through rollers, has a more uniform thickness but slightly less tensile strength compared to forged iron, affecting its long-term resilience under heavy loads. The longevity of forged iron surpasses rolled iron in applications requiring impact resistance and fatigue endurance, making it ideal for tools and structural components exposed to dynamic forces.

Applications: Where Forged Iron Excels

Forged iron is highly regarded in applications requiring exceptional strength and durability, such as automotive components, aerospace parts, and heavy machinery. Its grain structure continuity and enhanced mechanical properties make it ideal for load-bearing and high-stress environments. Industries demanding superior fatigue resistance and impact toughness preferentially utilize forged iron over rolled iron.

Applications: Rolled Iron in Modern Industry

Rolled iron is extensively used in modern industry for structural applications due to its uniform strength and precise dimensions, making it ideal for construction frameworks, automotive components, and machinery parts. Its consistent grain structure enhances durability and resistance to stress, which is crucial in manufacturing high-performance equipment and infrastructure. The scalability of rolled iron production supports large-scale projects requiring standardized materials with reliable mechanical properties.

Cost Considerations: Forged vs Rolled Iron

Forged iron generally incurs higher costs than rolled iron due to its labor-intensive manufacturing process, which involves heating and shaping metal using compressive forces, resulting in superior strength and durability. Rolled iron is produced by passing metal through rollers at high temperatures, enabling mass production with lower material waste and faster turnaround times, thus reducing overall expenses. For projects with budget constraints, rolled iron offers a more economical solution, while forged iron justifies its premium price through enhanced mechanical properties suited for high-stress applications.

Environmental Impact of Iron Forming Methods

Forged iron typically consumes less energy than rolled iron due to its more straightforward production process, resulting in a lower carbon footprint. Rolled iron involves higher temperatures and continuous processing that increase greenhouse gas emissions and resource consumption. Choosing forged iron can reduce environmental impact by minimizing energy use and material waste during manufacturing.

Choosing the Right Iron Type for Your Project

Forged iron offers superior strength and durability due to its solid metal structure, making it ideal for heavy-duty applications such as architectural elements and tools. Rolled iron, produced through a rolling process, provides consistent thickness and is often preferred for projects requiring uniformity and ease of fabrication, like sheet metalwork and structural components. Selecting forged or rolled iron depends on project requirements for strength, flexibility, and surface finish to ensure optimal performance and longevity.

Forged Iron vs Rolled Iron Infographic

materialdif.com

materialdif.com