Machineable iron is engineered for ease of machining, featuring a microstructure that allows for precise cutting and shaping without excessive tool wear, making it ideal for components requiring detailed fabrication. Abrasive resistant iron, on the other hand, is designed to withstand high wear conditions, incorporating hardened phases or alloying elements to resist surface degradation caused by friction and abrasion. Selecting between machineable and abrasive resistant iron depends on the application's need for either machinability or durability against abrasive forces.

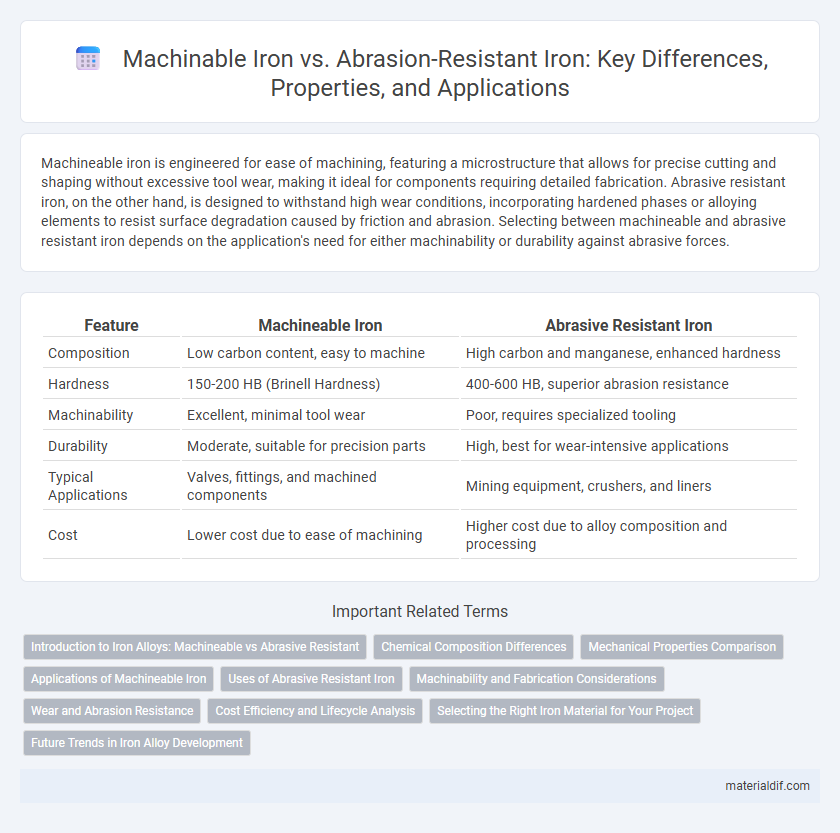

Table of Comparison

| Feature | Machineable Iron | Abrasive Resistant Iron |

|---|---|---|

| Composition | Low carbon content, easy to machine | High carbon and manganese, enhanced hardness |

| Hardness | 150-200 HB (Brinell Hardness) | 400-600 HB, superior abrasion resistance |

| Machinability | Excellent, minimal tool wear | Poor, requires specialized tooling |

| Durability | Moderate, suitable for precision parts | High, best for wear-intensive applications |

| Typical Applications | Valves, fittings, and machined components | Mining equipment, crushers, and liners |

| Cost | Lower cost due to ease of machining | Higher cost due to alloy composition and processing |

Introduction to Iron Alloys: Machineable vs Abrasive Resistant

Iron alloys vary significantly in composition and properties to suit diverse industrial applications; machineable iron is designed for ease of machining with enhanced chip control and dimensional accuracy, typically containing higher sulfur content to improve machinability. Abrasive resistant iron, in contrast, features high carbon and alloying elements such as chromium, manganese, and molybdenum, which enhance hardness and wear resistance for applications involving abrasive conditions. Understanding the metallurgical differences between machineable and abrasive resistant iron helps optimize material selection for manufacturing efficiency and durability in wear-intensive environments.

Chemical Composition Differences

Machineable iron typically contains higher sulfur and phosphorus levels, enhancing its machinability by promoting chip breakage and reducing tool wear. Abrasive resistant iron exhibits increased carbon and chromium content, which significantly improves hardness and wear resistance for extended durability in harsh conditions. The chemical composition distinctions directly influence the mechanical properties, tailoring each iron type to specific industrial applications.

Mechanical Properties Comparison

Machineable iron typically exhibits lower hardness, around 150-200 HB, with tensile strength ranging between 350-450 MPa, allowing for easy machining and good ductility. Abrasive resistant iron, such as high chromium white iron, showcases hardness levels exceeding 600 HB and tensile strength around 800-900 MPa, enhancing its wear resistance but reducing machinability and ductility. The mechanical property differences reflect trade-offs between ease of fabrication with machineable iron and durability against wear in abrasive resistant iron applications.

Applications of Machineable Iron

Machineable iron is commonly used in precision machining industries due to its excellent machinability and ability to achieve tight tolerances, making it ideal for components like gears, valve bodies, and pump housings. It is favored in applications requiring intricate shapes and fine details that can be accurately machined. Unlike abrasive resistant iron, machineable iron offers superior ease of fabrication, enhancing efficiency in manufacturing complex parts for automotive, aerospace, and industrial equipment sectors.

Uses of Abrasive Resistant Iron

Abrasive resistant iron is primarily used in industries requiring high wear protection, such as mining, cement production, and heavy machinery manufacturing. Its superior hardness and durability make it ideal for components like crusher liners, grinding balls, and wear plates that endure constant friction and impact. Machineable iron, while easier to shape and machine, lacks the abrasion resistance necessary for these demanding applications.

Machinability and Fabrication Considerations

Machineable iron exhibits superior machinability due to its microstructure designed for ease of cutting and shaping, making it ideal for precision components requiring minimal tool wear. Abrasive resistant iron, characterized by a harder, wear-resistant surface alloy, poses challenges during machining, often necessitating specialized tooling and slower cutting speeds to prevent tool degradation. Fabrication considerations favor machineable iron for complex geometries and tight tolerances, whereas abrasive resistant iron is preferred in environments with high wear demands despite its reduced machinability.

Wear and Abrasion Resistance

Machineable iron offers moderate wear resistance suitable for parts requiring precise machining and moderate durability, while abrasive resistant iron delivers superior abrasion resistance through hardened microstructures designed to withstand extreme wear conditions. Abrasive resistant iron's high chromium content and heat-treated surface enhance its ability to resist gouging and cutting from abrasive materials, making it ideal for heavy-duty industrial applications. In contrast, machineable iron prioritizes machinability over extreme durability, resulting in lower abrasion resistance compared to specialized abrasion resistant alloys.

Cost Efficiency and Lifecycle Analysis

Machineable iron offers superior cost efficiency due to lower machining expenses and reduced tool wear, making it ideal for components requiring precise shaping. Abrasive resistant iron extends lifecycle significantly in harsh operating environments, reducing replacement frequency despite a higher initial cost. Lifecycle analysis reveals that while machineable iron minimizes upfront expenses, abrasive resistant iron delivers better long-term value through enhanced durability and decreased downtime.

Selecting the Right Iron Material for Your Project

Selecting the right iron material depends on the specific application demands, where machinable iron offers excellent precision and ease of shaping for complex components, while abrasive resistant iron excels in durability and wear resistance in harsh environments. Machinable iron, typically enriched with sulfur and lead, provides lower hardness, facilitating intricate machining processes without tool wear. Abrasive resistant iron, characterized by high carbon and chromium content, withstands extreme abrasion, making it ideal for heavy-duty industrial parts exposed to constant friction and impact.

Future Trends in Iron Alloy Development

Future trends in iron alloy development emphasize enhancing machinability while maintaining or improving abrasive resistance, driven by advancements in microalloying and heat treatment techniques. Innovations such as nano-structured carbides and controlled microsegregation optimize wear resistance in abrasive resistant iron without compromising machinability required for complex machining operations. Research in additive manufacturing also enables customized iron alloys tailored for specific industrial applications, balancing durability and ease of machining through precise control of alloy composition and thermal processing.

Machineable Iron vs Abrasive Resistant Iron Infographic

materialdif.com

materialdif.com