Ferrous iron contains iron as its main component and is known for its magnetic properties and high tensile strength, making it essential in construction and manufacturing. Non-ferrous metals, which do not contain significant amounts of iron, are prized for their corrosion resistance, lightweight nature, and excellent electrical conductivity. Understanding the differences between ferrous and non-ferrous metals is crucial for selecting materials in engineering applications where durability and specific physical properties are required.

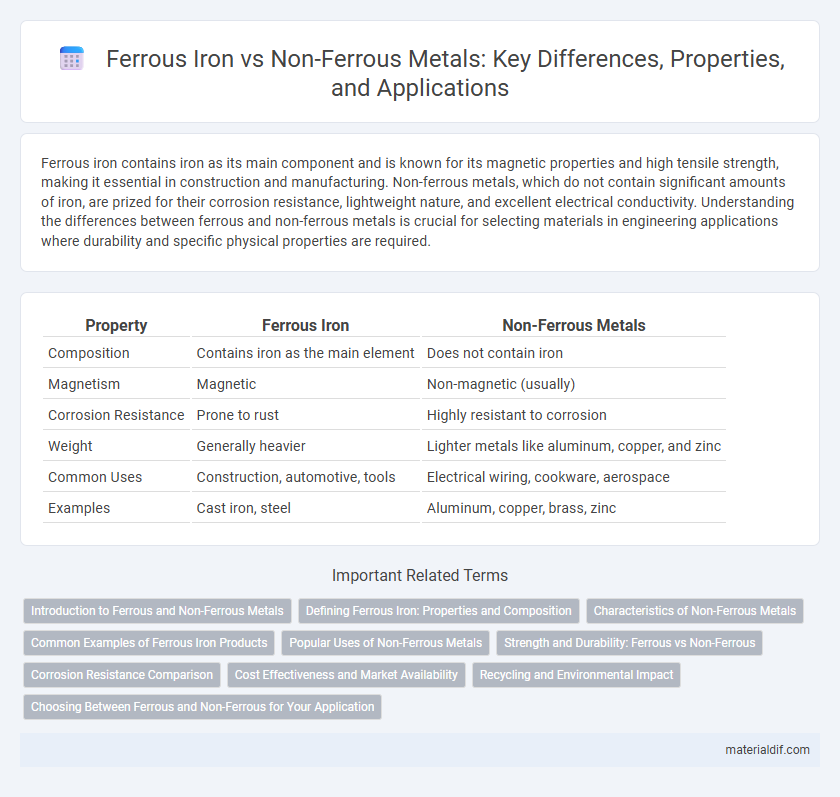

Table of Comparison

| Property | Ferrous Iron | Non-Ferrous Metals |

|---|---|---|

| Composition | Contains iron as the main element | Does not contain iron |

| Magnetism | Magnetic | Non-magnetic (usually) |

| Corrosion Resistance | Prone to rust | Highly resistant to corrosion |

| Weight | Generally heavier | Lighter metals like aluminum, copper, and zinc |

| Common Uses | Construction, automotive, tools | Electrical wiring, cookware, aerospace |

| Examples | Cast iron, steel | Aluminum, copper, brass, zinc |

Introduction to Ferrous and Non-Ferrous Metals

Ferrous metals primarily consist of iron and contain varying amounts of carbon, making them magnetic and prone to rust, with steel and cast iron as common examples. Non-ferrous metals, such as aluminum, copper, and zinc, lack iron, exhibit superior corrosion resistance, and are generally non-magnetic, used extensively in electrical wiring and aircraft manufacturing. The distinction between ferrous and non-ferrous metals is crucial for applications based on strength, weight, conductivity, and resistance to wear and corrosion.

Defining Ferrous Iron: Properties and Composition

Ferrous iron primarily consists of iron and carbon, characterized by its magnetic properties, high tensile strength, and susceptibility to rust and corrosion due to iron's affinity for oxygen and moisture. It exhibits a crystalline structure that enhances durability and is commonly alloyed with elements such as manganese and chromium to improve hardness and resistance. Unlike non-ferrous metals, ferrous iron contains significant iron content, making it essential in construction, automotive, and heavy machinery industries for structural applications.

Characteristics of Non-Ferrous Metals

Non-ferrous metals, such as copper, aluminum, and zinc, are characterized by their resistance to corrosion and superior conductivity compared to ferrous iron. These metals are typically lighter, non-magnetic, and possess higher malleability and ductility, making them ideal for electrical wiring, aerospace, and specialized industrial applications. Their ability to resist rust and oxidation enhances durability in environments unsuitable for ferrous metals.

Common Examples of Ferrous Iron Products

Ferrous iron products commonly include construction materials such as steel beams, rebar, and cast iron pipes, which are prized for their strength and durability. Automotive components like engine blocks and chassis parts are typically made from ferrous metals due to their magnetic properties and tensile strength. Unlike non-ferrous metals such as aluminum and copper, ferrous metals contain iron, making them more susceptible to rust but essential in heavy industrial applications.

Popular Uses of Non-Ferrous Metals

Non-ferrous metals such as aluminum, copper, and zinc are widely used in electrical wiring, aerospace components, and corrosion-resistant applications due to their superior conductivity and resistance to rust. Unlike ferrous iron, these metals are favored in industries requiring lightweight materials, such as automotive manufacturing and electronics, enhancing fuel efficiency and device performance. Their non-magnetic properties and recyclability make them essential for sustainable engineering and eco-friendly production processes.

Strength and Durability: Ferrous vs Non-Ferrous

Ferrous iron, containing significant amounts of iron, typically exhibits higher strength and durability compared to non-ferrous metals such as aluminum and copper, which are generally softer and more malleable. The presence of carbon and other alloying elements in ferrous metals enhances hardness, tensile strength, and resistance to wear, making them ideal for construction and heavy machinery applications. Non-ferrous metals, while offering superior corrosion resistance and lighter weight, often sacrifice strength, limiting their use in load-bearing or high-stress environments.

Corrosion Resistance Comparison

Ferrous iron, containing high iron content, is more prone to corrosion due to its susceptibility to rust when exposed to moisture and oxygen. Non-ferrous metals such as aluminum, copper, and zinc exhibit superior corrosion resistance because they naturally form protective oxide layers that prevent further degradation. The enhanced corrosion resistance of non-ferrous metals makes them ideal for environments with high moisture, reducing maintenance costs and extending material longevity.

Cost Effectiveness and Market Availability

Ferrous iron, primarily composed of iron and carbon alloys, offers greater cost effectiveness due to its abundant availability and lower production costs compared to non-ferrous metals such as aluminum, copper, and zinc. The widespread market availability of ferrous metals supports large-scale manufacturing and infrastructure projects, making them the preferred choice in industries prioritizing budget efficiency. Non-ferrous metals, while generally more expensive and less abundant, provide essential properties like corrosion resistance and electrical conductivity for specialized applications.

Recycling and Environmental Impact

Ferrous iron, primarily found in steel and cast iron, is highly recyclable, with recycling rates exceeding 70%, significantly reducing energy consumption and greenhouse gas emissions compared to primary production. Non-ferrous metals like aluminum and copper also offer high recyclability, but their recycling processes tend to be more energy-intensive and costly. Recycling ferrous metals lessens the need for mining, thus minimizing habitat destruction and environmental pollution, while non-ferrous metal recycling plays a critical role in conserving scarce natural resources and reducing toxic waste.

Choosing Between Ferrous and Non-Ferrous for Your Application

Ferrous iron, containing iron as its primary component, offers superior strength and magnetic properties, making it ideal for construction and automotive industries where durability is critical. Non-ferrous metals like aluminum and copper provide excellent corrosion resistance and lightweight characteristics, suited for electrical wiring and aerospace applications. Selecting between ferrous and non-ferrous metals depends on balancing factors such as strength requirements, weight limitations, and environmental exposure for your specific application.

Ferrous Iron vs Non-Ferrous Metals Infographic

materialdif.com

materialdif.com