Nodular iron, also known as ductile iron, features spherical graphite inclusions that enhance its strength and ductility, making it ideal for structural and automotive applications. Malleable iron undergoes a heat treatment process that transforms brittle white iron into a more flexible material with irregularly shaped graphite clusters, providing excellent toughness and machinability. Both materials offer superior castability, but nodular iron excels in tensile strength while malleable iron is preferred for complex shapes requiring impact resistance.

Table of Comparison

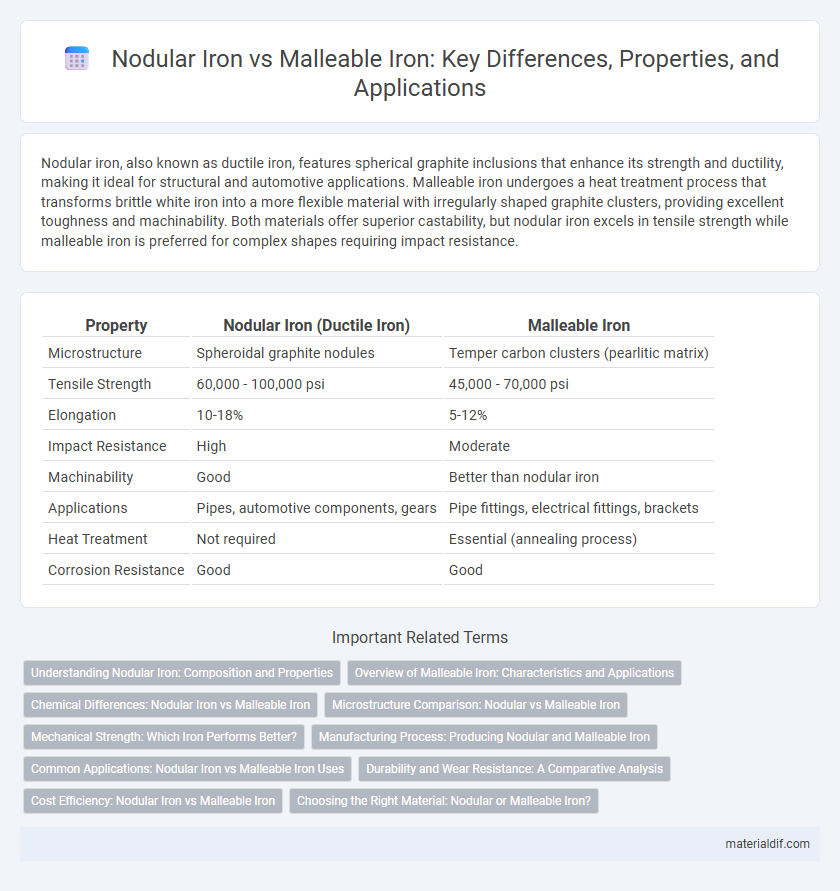

| Property | Nodular Iron (Ductile Iron) | Malleable Iron |

|---|---|---|

| Microstructure | Spheroidal graphite nodules | Temper carbon clusters (pearlitic matrix) |

| Tensile Strength | 60,000 - 100,000 psi | 45,000 - 70,000 psi |

| Elongation | 10-18% | 5-12% |

| Impact Resistance | High | Moderate |

| Machinability | Good | Better than nodular iron |

| Applications | Pipes, automotive components, gears | Pipe fittings, electrical fittings, brackets |

| Heat Treatment | Not required | Essential (annealing process) |

| Corrosion Resistance | Good | Good |

Understanding Nodular Iron: Composition and Properties

Nodular iron, also known as ductile iron, contains spherical graphite nodules that enhance its tensile strength and ductility compared to malleable iron, which has temper carbon in irregular clusters. The high magnesium content in nodular iron promotes graphite spheroidization, resulting in improved impact resistance and fatigue strength. This composition makes nodular iron suitable for applications requiring toughness and flexibility, such as automotive components and heavy machinery parts.

Overview of Malleable Iron: Characteristics and Applications

Malleable iron, created through heat treatment of white cast iron, exhibits enhanced ductility, toughness, and machinability compared to gray or nodular iron. Its microstructure, characterized by temper carbon nodules, provides excellent tensile strength and resistance to impact, making it ideal for applications such as pipe fittings, automotive components, and heavy machinery parts. The combination of castability and mechanical properties enables malleable iron to perform reliably in structural and load-bearing environments.

Chemical Differences: Nodular Iron vs Malleable Iron

Nodular iron contains a higher amount of magnesium, which promotes the formation of spherical graphite nodules that enhance ductility and strength. Malleable iron, on the other hand, undergoes an annealing process that transforms carbon from cementite into temper carbon clusters, resulting in a fibrous graphite structure that improves malleability. The chemical distinction lies primarily in the magnesium content and heat treatment, influencing the graphite morphology and mechanical properties of each iron type.

Microstructure Comparison: Nodular vs Malleable Iron

Nodular iron features a microstructure with spherical graphite nodules dispersed in a ferritic or pearlitic matrix, resulting in superior strength and ductility. Malleable iron exhibits tempered carbon clusters within a ferrite or pearlite matrix, formed by heat treating white cast iron to improve toughness and machinability. The microstructural differences lead to nodular iron offering higher tensile strength, while malleable iron provides enhanced impact resistance.

Mechanical Strength: Which Iron Performs Better?

Nodular iron, also known as ductile iron, exhibits superior mechanical strength compared to malleable iron due to its spherical graphite structure, which enhances tensile strength and impact resistance. Malleable iron offers good strength but is generally less strong and more brittle than nodular iron. For applications requiring high mechanical performance, nodular iron is typically the preferred choice.

Manufacturing Process: Producing Nodular and Malleable Iron

Nodular iron, also known as ductile iron, is produced by adding nodulizing elements such as magnesium or cerium to molten cast iron, causing carbon to form spherical graphite nodules during solidification, which enhances its ductility. Malleable iron is manufactured through a prolonged heat treatment process called annealing, where white cast iron is heated to around 900-950degC and held for several hours to transform brittle carbon flakes into temper carbon clusters, improving its malleability. The key difference lies in nodular iron's direct alloying during casting versus malleable iron's post-casting heat treatment to achieve desired mechanical properties.

Common Applications: Nodular Iron vs Malleable Iron Uses

Nodular iron, also known as ductile iron, is widely used in automotive components, heavy machinery, and pipelines due to its excellent tensile strength and impact resistance. Malleable iron is preferred for smaller, intricate parts such as fittings, electrical equipment, and hardware because of its superior ductility and machinability. The choice between nodular and malleable iron depends on the specific mechanical requirements and application environment.

Durability and Wear Resistance: A Comparative Analysis

Nodular iron exhibits superior durability due to its graphite nodules, which enhance tensile strength and impact resistance compared to malleable iron's temper carbon form. Wear resistance in nodular iron is generally higher, making it ideal for applications requiring prolonged exposure to mechanical stress. Malleable iron, while offering good ductility, tends to wear faster under abrasive conditions, limiting its use in heavy-duty environments.

Cost Efficiency: Nodular Iron vs Malleable Iron

Nodular iron, also known as ductile iron, offers higher cost efficiency than malleable iron due to its superior mechanical properties and lower processing expenses. The production of nodular iron involves less heat treatment, reducing energy consumption and manufacturing costs compared to the prolonged annealing required for malleable iron. Furthermore, nodular iron's enhanced strength and durability contribute to longer service life and reduced maintenance expenses in industrial applications.

Choosing the Right Material: Nodular or Malleable Iron?

Nodular iron, known for its superior tensile strength and ductility due to spheroidal graphite microstructure, is ideal for applications requiring high impact resistance and fatigue strength, such as automotive and heavy machinery components. Malleable iron, characterized by its excellent malleability after heat treatment and good machinability, suits applications needing moderate strength with enhanced ductility, commonly used in pipe fittings and hardware. Selecting between nodular and malleable iron depends on the mechanical performance requirements and the specific application environment, with nodular iron favored for structural resilience and malleable iron chosen for formability and ease of machining.

Nodular Iron vs Malleable Iron Infographic

materialdif.com

materialdif.com