Malleable iron offers excellent ductility and impact resistance due to its unique microstructure, making it ideal for intricate castings requiring flexibility. Steel provides superior tensile strength and hardness, suitable for applications demanding high load-bearing capacity and wear resistance. Choosing between malleable iron and steel depends on the balance between toughness and strength required for specific industrial uses.

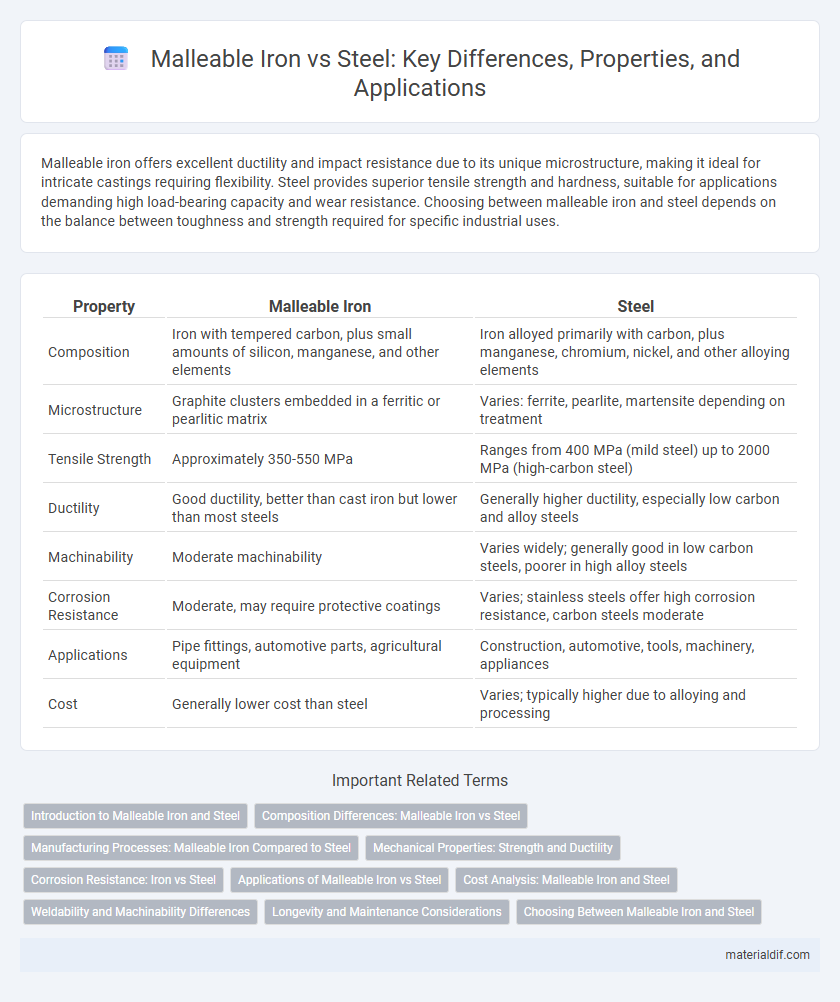

Table of Comparison

| Property | Malleable Iron | Steel |

|---|---|---|

| Composition | Iron with tempered carbon, plus small amounts of silicon, manganese, and other elements | Iron alloyed primarily with carbon, plus manganese, chromium, nickel, and other alloying elements |

| Microstructure | Graphite clusters embedded in a ferritic or pearlitic matrix | Varies: ferrite, pearlite, martensite depending on treatment |

| Tensile Strength | Approximately 350-550 MPa | Ranges from 400 MPa (mild steel) up to 2000 MPa (high-carbon steel) |

| Ductility | Good ductility, better than cast iron but lower than most steels | Generally higher ductility, especially low carbon and alloy steels |

| Machinability | Moderate machinability | Varies widely; generally good in low carbon steels, poorer in high alloy steels |

| Corrosion Resistance | Moderate, may require protective coatings | Varies; stainless steels offer high corrosion resistance, carbon steels moderate |

| Applications | Pipe fittings, automotive parts, agricultural equipment | Construction, automotive, tools, machinery, appliances |

| Cost | Generally lower cost than steel | Varies; typically higher due to alloying and processing |

Introduction to Malleable Iron and Steel

Malleable iron is a heat-treated cast iron known for its improved ductility and impact resistance, achieved through a prolonged annealing process that transforms brittle white iron into graphite clusters. Steel, an alloy of iron and carbon with varying other elements, offers a wide range of mechanical properties and higher tensile strength than malleable iron. While malleable iron provides excellent machinability and toughness for small castings, steel is preferred for applications requiring superior strength and flexibility.

Composition Differences: Malleable Iron vs Steel

Malleable iron contains a higher carbon content, typically between 2.0% to 3.0%, with silicon ranging from 1.8% to 2.5%, which promotes its unique nodular graphite structure after heat treatment. Steel generally has a lower carbon content, usually below 2.0%, and lacks the silicon levels found in malleable iron, resulting in a primarily iron-carbon alloy with varied microstructures such as ferrite, pearlite, or martensite. These compositional differences influence mechanical properties, making malleable iron more ductile and steel more versatile in hardness and tensile strength.

Manufacturing Processes: Malleable Iron Compared to Steel

Malleable iron is manufactured through a heat treatment process called annealing, which transforms white cast iron into a more ductile and malleable material by breaking down carbon clusters. Steel production involves melting iron with controlled amounts of carbon and other alloys, followed by processes such as casting, forging, or rolling to achieve specific mechanical properties. Compared to steel, malleable iron typically requires less precise control over alloy composition but more post-casting heat treatment to enhance its toughness and machinability.

Mechanical Properties: Strength and Ductility

Malleable iron exhibits lower tensile strength compared to steel, typically ranging from 400 to 700 MPa, but offers superior ductility with elongation rates of 12-18%, making it highly resistant to impact and deformation. Steel, depending on its alloy and treatment, can achieve tensile strengths exceeding 1000 MPa but generally has lower ductility, around 10-15%, which enhances its ability to withstand high loads without permanent deformation. The balance between strength and ductility in these materials dictates their application, with malleable iron favored for parts requiring toughness and flexibility, while steel is preferred for high-strength structural components.

Corrosion Resistance: Iron vs Steel

Malleable iron exhibits superior corrosion resistance compared to most carbon steels due to its microstructure, which contains fewer impurities and less susceptibility to rust formation. Steel, particularly low-alloy types, often requires protective coatings or treatments to prevent oxidation and corrosion in harsh environments. Understanding the specific alloy compositions and environmental factors is crucial when selecting between malleable iron and steel for applications exposed to moisture or corrosive elements.

Applications of Malleable Iron vs Steel

Malleable iron is commonly used in applications requiring excellent fatigue resistance and shock absorption, such as automotive components, pipe fittings, and agricultural machinery parts. Steel, with its higher tensile strength and versatility, is preferred for construction, large structural components, and high-stress machinery parts. The choice between malleable iron and steel depends on the specific mechanical properties needed and the environmental conditions of the application.

Cost Analysis: Malleable Iron and Steel

Malleable iron typically costs less than steel due to lower raw material expenses and simpler casting processes, making it a cost-effective choice for complex shapes and medium-strength applications. Steel offers higher strength and durability but involves higher costs from alloying elements and more energy-intensive manufacturing techniques. Evaluating total project requirements, including mechanical properties and fabrication methods, is essential to determine the most economical option between malleable iron and steel.

Weldability and Machinability Differences

Malleable iron offers better weldability than steel due to its cast structure that reduces cracking during welding processes. Steel generally exhibits superior machinability with available grades specifically designed for ease of cutting, drilling, and shaping compared to the harder microstructure of malleable iron. The weldability of malleable iron is enhanced by its nodular graphite, which minimizes thermal stress, whereas steel's machinability depends heavily on its carbon content and alloying elements.

Longevity and Maintenance Considerations

Malleable iron offers superior corrosion resistance compared to many steel variants, enhancing its longevity in outdoor and industrial applications. It requires less frequent maintenance due to its ability to withstand wear and tear without significant deformation or cracking. Steel, while stronger in tensile strength, often demands regular upkeep such as rust prevention treatments to ensure durability over time.

Choosing Between Malleable Iron and Steel

Malleable iron offers superior ductility and impact resistance compared to most steels, making it ideal for applications requiring flexibility and shock absorption. Steel provides higher tensile strength and hardness, suitable for structural components and heavy load-bearing uses. Selecting between malleable iron and steel hinges on balancing the need for toughness against strength, considering factors like machinability, cost, and environmental conditions.

Malleable Iron vs Steel Infographic

materialdif.com

materialdif.com