Powdered iron offers greater surface area and improved magnetic properties compared to solid iron, making it ideal for applications like inductors and transformers. Solid iron provides higher structural strength and durability, commonly used in construction and heavy machinery. Choosing between powdered and solid iron depends on the specific requirements for magnetic performance and mechanical integrity.

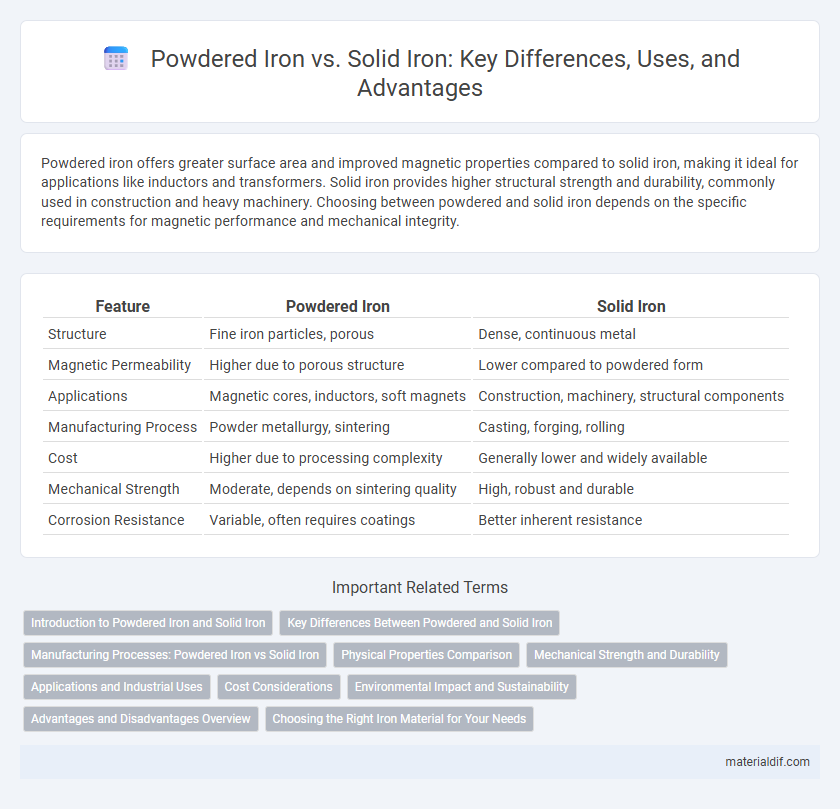

Table of Comparison

| Feature | Powdered Iron | Solid Iron |

|---|---|---|

| Structure | Fine iron particles, porous | Dense, continuous metal |

| Magnetic Permeability | Higher due to porous structure | Lower compared to powdered form |

| Applications | Magnetic cores, inductors, soft magnets | Construction, machinery, structural components |

| Manufacturing Process | Powder metallurgy, sintering | Casting, forging, rolling |

| Cost | Higher due to processing complexity | Generally lower and widely available |

| Mechanical Strength | Moderate, depends on sintering quality | High, robust and durable |

| Corrosion Resistance | Variable, often requires coatings | Better inherent resistance |

Introduction to Powdered Iron and Solid Iron

Powdered iron consists of fine granules formed through atomization or reduction processes, offering enhanced surface area and superior magnetic properties compared to solid iron. Solid iron is a dense, continuous metal with a uniform crystalline structure, providing higher tensile strength and durability in structural applications. The distinct microstructures of powdered and solid iron influence their suitability for uses in electromagnetic cores and mechanical components, respectively.

Key Differences Between Powdered and Solid Iron

Powdered iron consists of fine iron particles compressed into shapes, offering superior magnetic properties and enhanced machinability compared to solid iron, which is a dense, continuous metal form. Solid iron boasts higher structural strength and better conductivity, making it ideal for construction and heavy-duty applications, whereas powdered iron excels in electromagnetic components due to its controlled porosity and reduced eddy current losses. Key differences include variations in density, mechanical strength, magnetic permeability, and manufacturing processes, influencing their use in industries like electronics, automotive, and manufacturing.

Manufacturing Processes: Powdered Iron vs Solid Iron

Powdered iron is produced through atomization or reduction processes, resulting in fine metal particles pressed and sintered into desired shapes, allowing for intricate designs and precise control over material properties. Solid iron, typically formed through casting or forging, involves melting and cooling bulk iron to create dense, homogeneous structures with high mechanical strength. Manufacturing powdered iron enables enhanced magnetic and wear resistance properties, while solid iron offers superior structural integrity and durability for heavy-duty applications.

Physical Properties Comparison

Powdered iron consists of fine granules with high surface area, leading to increased porosity and lower density compared to solid iron, which is dense and possesses a uniform crystalline structure. The porous nature of powdered iron results in reduced mechanical strength but enhanced magnetic permeability, while solid iron exhibits greater tensile strength and thermal conductivity. Understanding these physical property differences is crucial for applications in electromagnetic components where permeability and density play pivotal roles.

Mechanical Strength and Durability

Powdered iron exhibits lower mechanical strength compared to solid iron due to its porous microstructure resulting from sintering processes, which can lead to reduced load-bearing capacity. Solid iron, characterized by a dense, continuous crystalline matrix, offers superior durability and resistance to mechanical deformation under stress. Applications requiring high tensile strength and long-term wear resistance typically favor solid iron for enhanced structural integrity.

Applications and Industrial Uses

Powdered iron is extensively utilized in manufacturing electromagnetic components such as inductors and transformers due to its high permeability and reduced eddy current losses. Solid iron finds primary application in construction, automotive, and heavy machinery industries where structural strength and durability are critical. Industrial uses of powdered iron include powder metallurgy for producing complex shapes with precise dimensions, while solid iron is preferred for beams, shafts, and engine blocks requiring robustness.

Cost Considerations

Powdered iron typically incurs higher production costs due to specialized manufacturing processes like atomization and compaction compared to solid iron's straightforward casting or forging methods. The cost-effectiveness of solid iron is evident in bulk applications where large quantities are required, making it preferred for structural uses. However, powdered iron offers cost advantages in precision parts with complex geometries by reducing material waste and machining time.

Environmental Impact and Sustainability

Powdered iron offers enhanced sustainability through its recyclability and lower energy consumption in manufacturing compared to solid iron, which typically requires intensive smelting processes. The fine particle structure of powdered iron reduces material waste and enables more efficient raw material use, minimizing the carbon footprint. In contrast, solid iron production emits higher greenhouse gases and contributes to greater environmental degradation due to mining and ore processing demands.

Advantages and Disadvantages Overview

Powdered iron offers superior magnetic properties, enhanced machinability, and cost-effective manufacturing for complex shapes, making it ideal for electromagnetic applications. Solid iron provides greater mechanical strength and durability, suitable for structural uses but involves higher material waste and machining challenges. Powdered iron's porosity can reduce density and strength, while solid iron's uniform structure supports higher load-bearing capabilities.

Choosing the Right Iron Material for Your Needs

Powdered iron offers superior versatility for complex shapes and electromagnetic applications due to its ability to be molded and its magnetic properties, while solid iron provides greater structural strength and durability for construction and heavy-duty uses. Selecting the right iron material depends on the specific requirements such as mechanical strength, magnetic permeability, and manufacturing processes. Consider powdered iron for precision components in electronics, and solid iron for robust frameworks where tensile strength is critical.

Powdered Iron vs Solid Iron Infographic

materialdif.com

materialdif.com