Iron ore is a naturally occurring mineral extracted from the earth, primarily composed of iron oxides that require smelting to separate pure iron. Processed iron undergoes refining techniques such as smelting and alloying to increase its strength, ductility, and suitability for manufacturing. The transition from iron ore to processed iron is essential for producing steel and other iron-based products used in construction and industry.

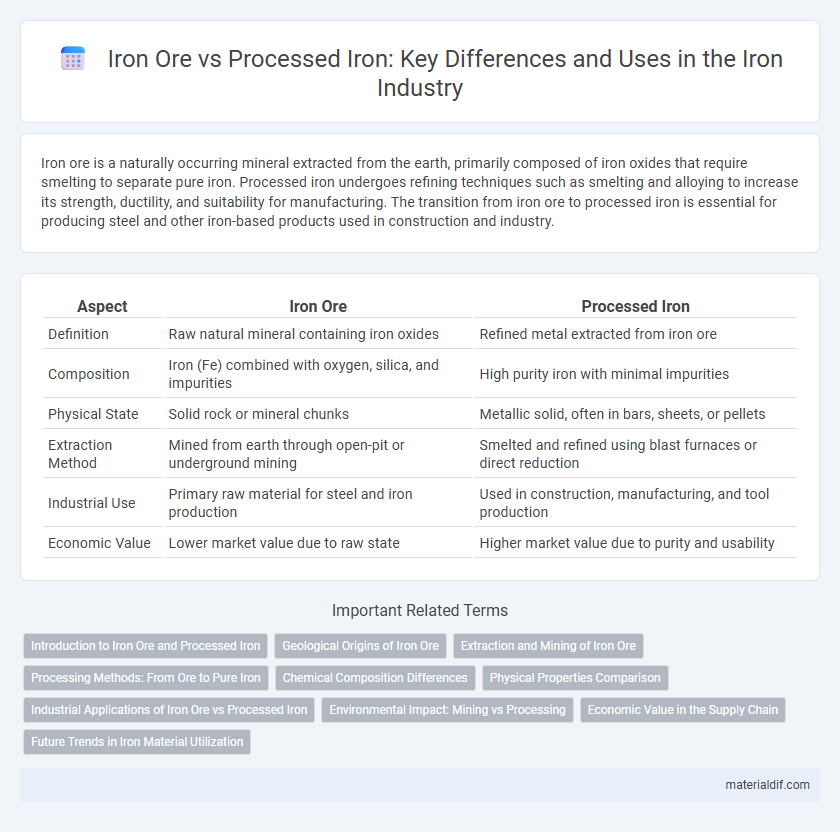

Table of Comparison

| Aspect | Iron Ore | Processed Iron |

|---|---|---|

| Definition | Raw natural mineral containing iron oxides | Refined metal extracted from iron ore |

| Composition | Iron (Fe) combined with oxygen, silica, and impurities | High purity iron with minimal impurities |

| Physical State | Solid rock or mineral chunks | Metallic solid, often in bars, sheets, or pellets |

| Extraction Method | Mined from earth through open-pit or underground mining | Smelted and refined using blast furnaces or direct reduction |

| Industrial Use | Primary raw material for steel and iron production | Used in construction, manufacturing, and tool production |

| Economic Value | Lower market value due to raw state | Higher market value due to purity and usability |

Introduction to Iron Ore and Processed Iron

Iron ore is a naturally occurring mineral from which metallic iron is extracted, primarily composed of iron oxides such as hematite and magnetite. Processed iron, on the other hand, refers to iron that has been refined and purified through processes like smelting and casting, resulting in materials such as pig iron, wrought iron, and steel. The distinction between raw iron ore and processed iron is critical for industries relying on high-strength materials and specific alloy compositions.

Geological Origins of Iron Ore

Iron ore forms primarily in banded iron formations (BIFs) dating back to the Precambrian era, composed of alternating layers of iron-rich minerals and silica. These deposits result from ancient oceanic chemical precipitation under specific redox conditions, where dissolved iron combined with oxygen produced magnetite and hematite minerals. Processed iron, derived from smelting iron ore, benefits from this geological concentration of iron oxides, enabling efficient metal extraction and refining for industrial applications.

Extraction and Mining of Iron Ore

Iron ore is extracted through surface mining techniques such as open-pit and strip mining, targeting iron-rich minerals like hematite and magnetite found in sedimentary rocks. Extraction involves blasting, drilling, and hauling the ore to processing plants where it undergoes crushing, grinding, and magnetic separation to concentrate the iron content. This raw concentrate is eventually smelted in blast furnaces to produce processed iron, which is refined and alloyed for use in steel manufacturing.

Processing Methods: From Ore to Pure Iron

Iron ore undergoes crushing, grinding, and magnetic separation to concentrate the iron content before smelting in blast furnaces at temperatures exceeding 1,500degC. The smelting process reduces iron oxides to metallic iron using coke as a reducing agent, producing pig iron with high carbon content. Subsequent refining methods such as basic oxygen furnace (BOF) or electric arc furnace (EAF) reduce carbon levels and impurities, resulting in processed iron or steel with enhanced strength and ductility.

Chemical Composition Differences

Iron ore primarily consists of iron oxides such as hematite (Fe2O3) and magnetite (Fe3O4), containing impurities like silica, phosphorus, and sulfur that affect its quality. Processed iron, refined through smelting, results in a higher concentration of elemental iron (Fe) typically above 90%, with reduced oxygen and impurity levels. This transformation enhances the metal's purity and reactivity, making processed iron more suitable for steel production and industrial applications.

Physical Properties Comparison

Iron ore is a naturally occurring mineral rich in iron oxides, typically exhibiting a rough, grainy texture and varying in color from reddish-brown to dark gray, with a high hardness and brittleness. Processed iron, derived from smelting iron ore, has a uniform metallic luster, greater malleability, and enhanced tensile strength due to the removal of impurities and controlled alloying. The density of processed iron is significantly higher, typically around 7.8 g/cm3, compared to varying densities of iron ore depending on its specific composition and moisture content.

Industrial Applications of Iron Ore vs Processed Iron

Iron ore serves as the primary raw material for extracting iron, predominantly used in steel manufacturing and construction industries. Processed iron, including cast iron and wrought iron, is essential for producing machinery, automotive parts, and infrastructure components due to its enhanced strength and malleability. Industrial applications rely heavily on processed iron for precision engineering, whereas iron ore is crucial for large-scale steel production and heavy industry.

Environmental Impact: Mining vs Processing

Iron ore mining generates significant environmental impacts including habitat destruction, soil erosion, and water contamination due to the extraction and transportation processes. Processed iron involves energy-intensive refining and smelting, which contribute to high carbon emissions and air pollution from the release of greenhouse gases and particulate matter. The environmental footprint of processed iron is largely driven by fossil fuel consumption, whereas mining impacts primarily disrupt local ecosystems and water resources.

Economic Value in the Supply Chain

Iron ore serves as the foundational raw material with substantial economic value due to its abundance and critical role in steel production, yet its low market price contrasts sharply with processed iron, which commands higher value through added manufacturing and refinement. The transformation from iron ore to processed iron significantly elevates economic value by enabling diverse industrial applications, increasing demand, and supporting employment across supply chain sectors. Efficient processing and refinement technologies maximize value extraction, optimizing profitability and competitiveness in global iron markets.

Future Trends in Iron Material Utilization

The future trends in iron material utilization emphasize increasing efficiency in converting iron ore to processed iron through advanced beneficiation and smelting technologies, reducing environmental impact and energy consumption. Innovations such as hydrogen-based direct reduction and electrification of steelmaking processes are poised to transform the iron industry by lowering carbon emissions and improving material quality. Growing demand for high-strength, lightweight iron alloys in automotive and construction sectors drives research into novel iron composites and recycling techniques to support sustainable development.

Iron Ore vs Processed Iron Infographic

materialdif.com

materialdif.com