Carburized iron undergoes a heat treatment process where carbon is diffused into the surface, significantly increasing hardness and wear resistance, ideal for heavy-duty applications. Annealed iron, subjected to slow cooling after heating, exhibits improved ductility and reduced internal stresses, making it easier to machine and form. The choice between carburized and annealed iron depends on the required balance of toughness and workability for specific industrial uses.

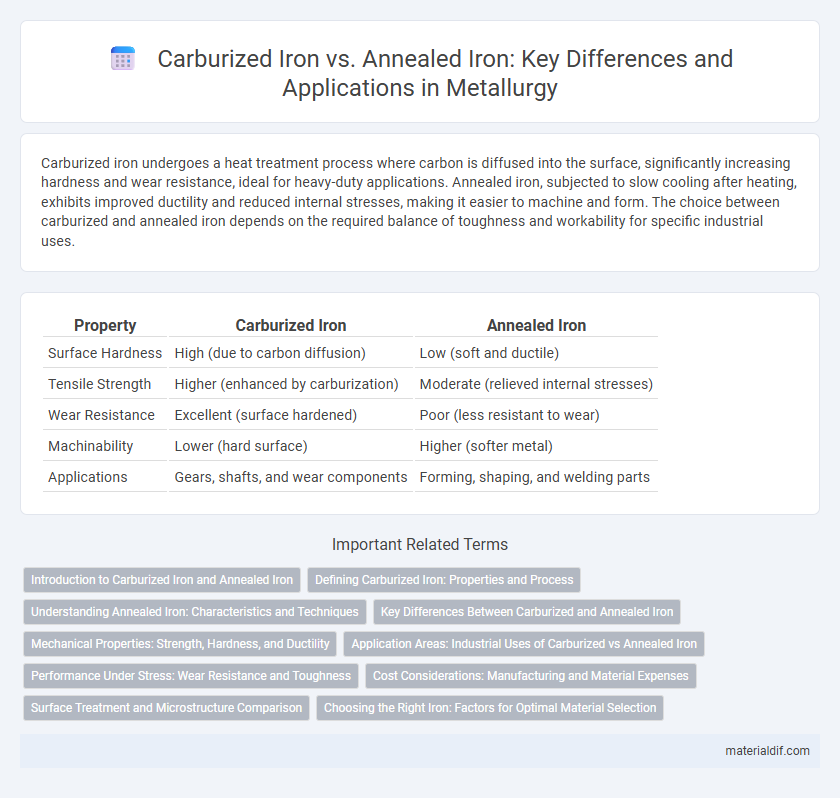

Table of Comparison

| Property | Carburized Iron | Annealed Iron |

|---|---|---|

| Surface Hardness | High (due to carbon diffusion) | Low (soft and ductile) |

| Tensile Strength | Higher (enhanced by carburization) | Moderate (relieved internal stresses) |

| Wear Resistance | Excellent (surface hardened) | Poor (less resistant to wear) |

| Machinability | Lower (hard surface) | Higher (softer metal) |

| Applications | Gears, shafts, and wear components | Forming, shaping, and welding parts |

Introduction to Carburized Iron and Annealed Iron

Carburized iron is a type of iron that has undergone a heat treatment process to infuse carbon into its surface, enhancing hardness and wear resistance. Annealed iron refers to iron that has been heated and then slowly cooled to reduce hardness, improve ductility, and relieve internal stresses. These treatments alter the microstructure of iron to optimize its mechanical properties for specific industrial applications.

Defining Carburized Iron: Properties and Process

Carburized iron undergoes a heat treatment process where carbon is diffused into the surface layer, significantly enhancing its hardness and wear resistance while maintaining a tough interior core. This process involves heating the iron in a carbon-rich environment at temperatures between 900degC and 950degC, followed by quenching to lock in the carbon-enriched surface. The resulting microstructure exhibits a hardened case with improved fatigue strength, making carburized iron ideal for gears, shafts, and components subjected to high surface stress.

Understanding Annealed Iron: Characteristics and Techniques

Annealed iron undergoes a heat treatment process that softens the metal, enhancing its ductility, machinability, and toughness. This technique involves heating the iron to a specific temperature and then slowly cooling it to relieve internal stresses and improve crystal structure uniformity. As a result, annealed iron is preferred in applications requiring high malleability and resistance to cracking compared to carburized iron, which is hardened for surface durability.

Key Differences Between Carburized and Annealed Iron

Carburized iron undergoes a heat treatment process that infuses carbon into its surface, significantly enhancing its hardness and wear resistance compared to annealed iron. Annealed iron is subjected to controlled heating and slow cooling to reduce hardness and increase ductility, making it more malleable and suitable for shaping. The fundamental difference lies in carburized iron's surface carbon enrichment for toughness, while annealed iron is softened throughout for improved machinability and reduced brittleness.

Mechanical Properties: Strength, Hardness, and Ductility

Carburized iron exhibits significantly increased surface hardness and strength due to carbon diffusion, enhancing wear resistance while maintaining a tougher core. Annealed iron offers improved ductility and reduced internal stresses, resulting in lower hardness but greater malleability and toughness. The choice between carburized and annealed iron depends on balancing surface hardness requirements against overall material ductility and strength demands.

Application Areas: Industrial Uses of Carburized vs Annealed Iron

Carburized iron, with its hardened surface and improved wear resistance, is extensively used in automotive components, gears, and heavy machinery parts requiring high surface durability. Annealed iron, known for its enhanced ductility and machinability, is preferred in applications such as structural frameworks, pipelines, and manufacturing of complex shaped parts where forming and welding are essential. Industrial sectors leverage carburized iron for wear-intensive environments, while annealed iron suits applications demanding flexibility and ease of fabrication.

Performance Under Stress: Wear Resistance and Toughness

Carburized iron exhibits superior wear resistance due to its hardened carbon-rich surface layer, making it ideal for applications subject to abrasive stress. Annealed iron, with its softened and ductile microstructure, offers enhanced toughness, allowing it to absorb impact and resist cracking under sudden loads. Performance under stress varies as carburized iron prioritizes surface hardness, while annealed iron balances toughness and malleability for durability in dynamic environments.

Cost Considerations: Manufacturing and Material Expenses

Carburized iron incurs higher manufacturing costs due to the specialized heat treatment process that introduces carbon to the surface, enhancing wear resistance and hardness. Annealed iron, by contrast, involves a simpler heat treatment that softens the metal, resulting in lower material and labor expenses. Choosing between carburized and annealed iron depends largely on budget constraints and the specific durability requirements of the application.

Surface Treatment and Microstructure Comparison

Carburized iron undergoes a surface treatment process that introduces carbon into the outer layer, resulting in a hard, wear-resistant surface with a martensitic microstructure, while the core remains softer and ductile. Annealed iron is subjected to a heat treatment that softens the entire material, producing a uniform, ferritic or pearlitic microstructure, which enhances machinability and toughness but reduces surface hardness. The carburization process significantly improves surface durability compared to the annealed state, making carburized iron ideal for wear applications, whereas annealed iron excels in forming and machining tasks.

Choosing the Right Iron: Factors for Optimal Material Selection

Carburized iron offers enhanced surface hardness and wear resistance due to its carbon-enriched outer layer, making it ideal for applications requiring durability under friction. Annealed iron, on the other hand, provides improved ductility and machinability by relieving internal stresses through controlled heating and cooling processes. Selecting the right iron depends on balancing hardness requirements against flexibility and ease of fabrication for the intended industrial application.

Carburized Iron vs Annealed Iron Infographic

materialdif.com

materialdif.com