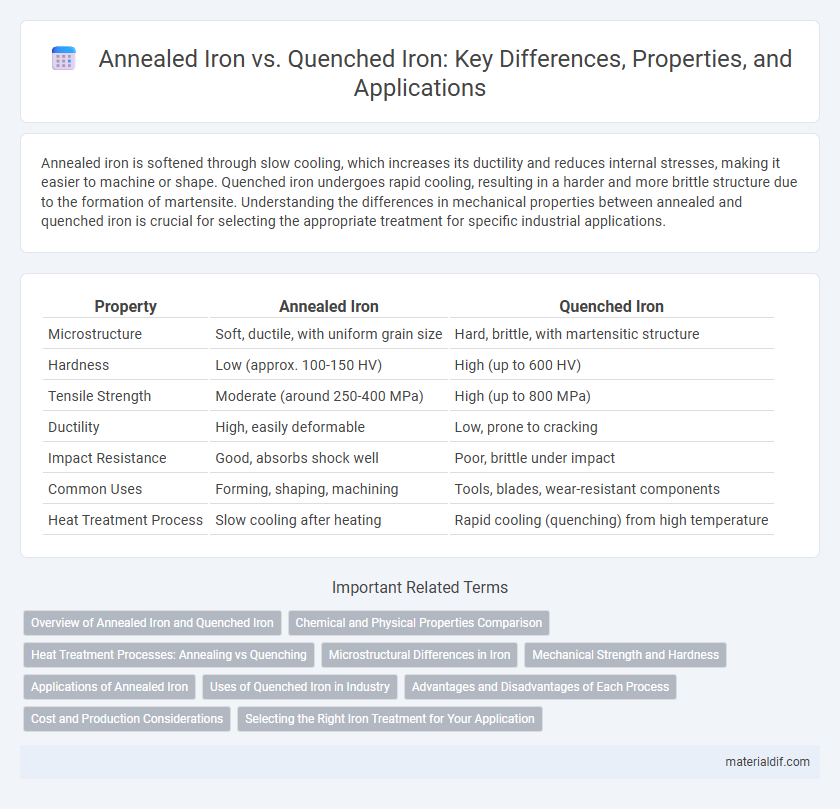

Annealed iron is softened through slow cooling, which increases its ductility and reduces internal stresses, making it easier to machine or shape. Quenched iron undergoes rapid cooling, resulting in a harder and more brittle structure due to the formation of martensite. Understanding the differences in mechanical properties between annealed and quenched iron is crucial for selecting the appropriate treatment for specific industrial applications.

Table of Comparison

| Property | Annealed Iron | Quenched Iron |

|---|---|---|

| Microstructure | Soft, ductile, with uniform grain size | Hard, brittle, with martensitic structure |

| Hardness | Low (approx. 100-150 HV) | High (up to 600 HV) |

| Tensile Strength | Moderate (around 250-400 MPa) | High (up to 800 MPa) |

| Ductility | High, easily deformable | Low, prone to cracking |

| Impact Resistance | Good, absorbs shock well | Poor, brittle under impact |

| Common Uses | Forming, shaping, machining | Tools, blades, wear-resistant components |

| Heat Treatment Process | Slow cooling after heating | Rapid cooling (quenching) from high temperature |

Overview of Annealed Iron and Quenched Iron

Annealed iron undergoes a controlled heating and slow cooling process to enhance ductility, reduce hardness, and relieve internal stresses, making it easier to machine and shape for various industrial applications. Quenched iron is rapidly cooled from a high temperature, resulting in increased hardness and strength but reduced ductility, often used in tools and components requiring wear resistance. The primary distinction lies in thermal treatment methods, which directly influence mechanical properties tailored to specific engineering needs.

Chemical and Physical Properties Comparison

Annealed iron exhibits a more uniform microstructure with reduced internal stresses, resulting in enhanced ductility and lower hardness compared to quenched iron. Quenched iron undergoes rapid cooling, increasing hardness and tensile strength but making it more brittle due to the formation of martensitic phases. Chemically, both types maintain similar elemental composition, but their physical properties differ significantly due to variations in crystalline structure induced by their distinct heat treatment processes.

Heat Treatment Processes: Annealing vs Quenching

Annealed iron undergoes a slow cooling heat treatment process that softens the metal, improving ductility and reducing internal stresses, making it ideal for machining and forming applications. Quenched iron is rapidly cooled from a high temperature, typically in water or oil, resulting in increased hardness and strength due to the formation of martensitic microstructure. These distinct heat treatment processes directly influence the mechanical properties and suitability of iron for various industrial applications.

Microstructural Differences in Iron

Annealed iron exhibits a uniform, coarse-grained microstructure due to slow cooling, which reduces internal stresses and enhances ductility. Quenched iron, cooled rapidly from high temperature, features a fine martensitic or bainitic structure that increases hardness and strength but reduces toughness. These microstructural differences directly influence iron's mechanical properties and suitability for various industrial applications.

Mechanical Strength and Hardness

Annealed iron exhibits lower mechanical strength and hardness due to its soft, ductile microstructure formed by slow cooling, making it more malleable and easier to machine. Quenched iron undergoes rapid cooling, resulting in a harder, more brittle structure with significantly increased mechanical strength and hardness, ideal for wear-resistant applications. The choice between annealed and quenched iron depends on balancing toughness and durability requirements in engineering designs.

Applications of Annealed Iron

Annealed iron exhibits enhanced ductility and machinability, making it ideal for applications requiring extensive shaping and forming, such as automotive body panels and structural components. Its softened microstructure reduces brittleness, enabling precise machining for intricate parts in electrical appliances and machinery. The improved malleability also supports manufacturing processes in construction materials and metalworking industries.

Uses of Quenched Iron in Industry

Quenched iron exhibits enhanced hardness and tensile strength due to rapid cooling, making it ideal for industrial applications requiring high wear resistance, such as manufacturing cutting tools, gears, and molds. Its superior durability is essential in automotive components and heavy machinery, where resistance to deformation and impact is critical. Quenched iron's ability to maintain structural integrity under stress ensures reliability in construction and engineering projects demanding tough, resilient materials.

Advantages and Disadvantages of Each Process

Annealed iron offers enhanced ductility and reduced internal stresses, making it ideal for applications requiring easy shaping and welding, but it has lower hardness and strength compared to quenched iron. Quenched iron provides superior hardness and tensile strength due to rapid cooling, which improves wear resistance but increases brittleness and susceptibility to cracking under impact. Choosing between annealed and quenched iron depends on whether flexibility and machinability or hardness and durability are the primary requirements for the intended use.

Cost and Production Considerations

Annealed iron undergoes a controlled cooling process that reduces internal stresses, making it less brittle but more costly due to longer production times and energy consumption. Quenched iron, cooled rapidly from a high temperature, is cheaper to produce because of faster processing but often requires additional treatments to prevent brittleness and enhance durability. Manufacturing decisions weigh the higher cost of annealing against the quicker, more economical quenching, depending on the intended use and mechanical property requirements.

Selecting the Right Iron Treatment for Your Application

Annealed iron offers enhanced ductility and reduced hardness, making it ideal for applications requiring extensive shaping or bending without cracking. Quenched iron, subjected to rapid cooling, provides superior hardness and strength, suited for wear-resistant parts and heavy-duty use. Assessing factors like mechanical strength, flexibility, and intended operational stress ensures selecting the right iron treatment optimizes performance and longevity.

Annealed Iron vs Quenched Iron Infographic

materialdif.com

materialdif.com