Carbon steel contains varying amounts of carbon that significantly enhance its strength, hardness, and durability compared to pure iron. Pure iron exhibits excellent ductility and corrosion resistance but lacks the mechanical strength necessary for many structural applications. The addition of carbon transforms pure iron into a versatile material ideal for construction, tools, and machinery due to its improved hardness and wear resistance.

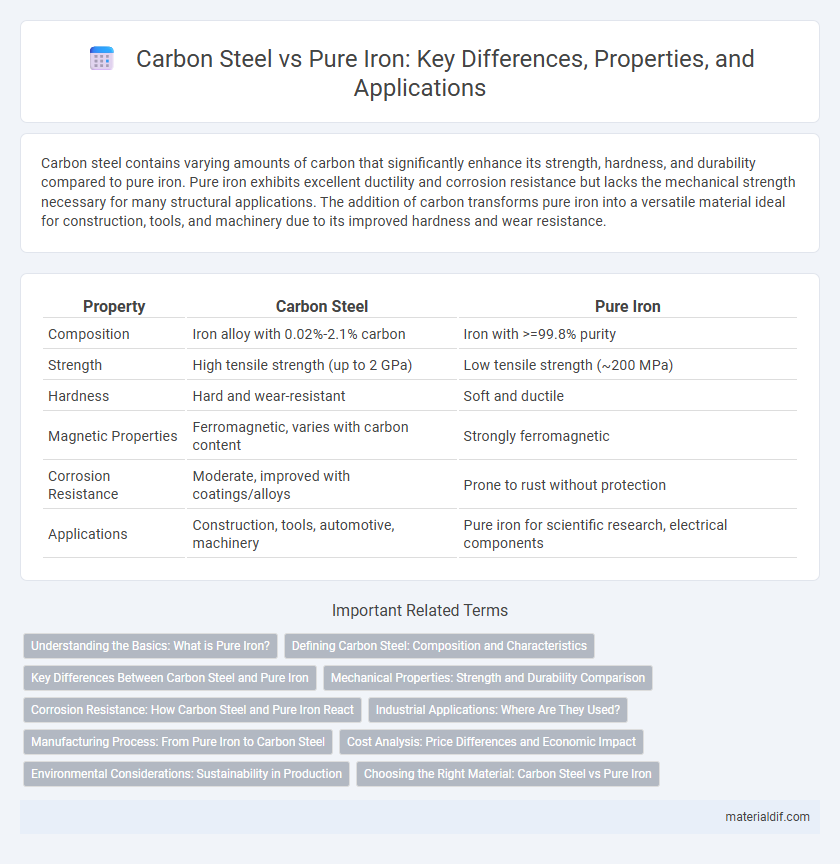

Table of Comparison

| Property | Carbon Steel | Pure Iron |

|---|---|---|

| Composition | Iron alloy with 0.02%-2.1% carbon | Iron with >=99.8% purity |

| Strength | High tensile strength (up to 2 GPa) | Low tensile strength (~200 MPa) |

| Hardness | Hard and wear-resistant | Soft and ductile |

| Magnetic Properties | Ferromagnetic, varies with carbon content | Strongly ferromagnetic |

| Corrosion Resistance | Moderate, improved with coatings/alloys | Prone to rust without protection |

| Applications | Construction, tools, automotive, machinery | Pure iron for scientific research, electrical components |

Understanding the Basics: What is Pure Iron?

Pure iron consists of nearly 99.8% iron, offering high malleability and excellent corrosion resistance but limited strength. Carbon steel is an alloy combining iron with carbon content typically between 0.02% and 2.1%, resulting in increased hardness and tensile strength compared to pure iron. Understanding pure iron's minimal alloying elements helps reveal its softness and susceptibility to wear, distinguishing its fundamental properties from carbon steel.

Defining Carbon Steel: Composition and Characteristics

Carbon steel is an alloy primarily composed of iron and carbon, with carbon content typically ranging from 0.02% to 2.1%, providing enhanced strength and hardness compared to pure iron. The presence of carbon influences the microstructure, resulting in improved tensile strength, wear resistance, and durability, making it suitable for construction and manufacturing applications. Unlike pure iron, which is softer and more ductile, carbon steel exhibits greater mechanical properties due to the carbon atoms disrupting the iron crystal lattice.

Key Differences Between Carbon Steel and Pure Iron

Carbon steel contains carbon content typically ranging from 0.02% to 2.1%, which significantly enhances its hardness, strength, and wear resistance compared to pure iron. Pure iron is softer, more ductile, and exhibits excellent magnetic properties, but it lacks the mechanical strength and durability found in carbon steel. The microstructure of carbon steel includes iron and iron carbides, while pure iron primarily consists of a nearly pure ferrite phase with minimal impurities.

Mechanical Properties: Strength and Durability Comparison

Carbon steel exhibits significantly higher tensile strength and hardness compared to pure iron due to the presence of carbon atoms that create a stronger iron lattice structure. The added carbon content enhances wear resistance and durability, making carbon steel more suitable for heavy-duty applications and structural components. Pure iron, while more ductile and malleable, offers lower strength and is more prone to deformation under stress, limiting its use in high-strength materials.

Corrosion Resistance: How Carbon Steel and Pure Iron React

Carbon steel exhibits superior corrosion resistance compared to pure iron due to the presence of carbon, which enhances the formation of a protective oxide layer that slows rusting. Pure iron, with its high ductility and low carbon content, is more prone to rapid oxidation and surface degradation when exposed to moisture and oxygen. Consequently, carbon steel is preferred in environments requiring greater durability and resistance to corrosion.

Industrial Applications: Where Are They Used?

Carbon steel, containing up to 2% carbon, is widely used in construction, automotive, and heavy machinery industries due to its enhanced strength, hardness, and durability. Pure iron, characterized by its high malleability and excellent corrosion resistance, finds applications in electrical transformers, magnetic cores, and specialized chemical equipment. Industrial sectors prefer carbon steel for structural components requiring mechanical strength, while pure iron is favored in roles demanding high electrical conductivity and corrosion resistance.

Manufacturing Process: From Pure Iron to Carbon Steel

The manufacturing process transforms pure iron by incorporating controlled amounts of carbon, enhancing hardness and strength through techniques like smelting and refining in blast furnaces followed by alloying in steelmaking converters. Carbon steel production involves precise carbon content adjustment, typically between 0.02% and 2.14%, which significantly alters the microstructure compared to nearly 100% pure iron. This process also includes heat treatments such as quenching and tempering to optimize mechanical properties for various industrial applications.

Cost Analysis: Price Differences and Economic Impact

Carbon steel typically costs significantly less than pure iron due to its widespread industrial use and easier processing methods, making it a more economical choice for manufacturing. Pure iron's higher price stems from its refinement requirements and lower availability, leading to greater expenses in production and procurement. This price disparity influences construction and manufacturing industries by promoting carbon steel as the preferred material to minimize costs while maintaining sufficient strength and durability.

Environmental Considerations: Sustainability in Production

Carbon steel production involves higher energy consumption and carbon emissions due to alloying processes and heat treatment compared to pure iron, which requires less intensive processing. Recycling carbon steel contributes significantly to reducing environmental impact, as it cuts down on raw material extraction and energy use, enhancing sustainability. Pure iron's limited industrial application and lower demand result in a smaller ecological footprint, although its mechanical properties restrict widespread replacement of carbon steel.

Choosing the Right Material: Carbon Steel vs Pure Iron

Carbon steel contains varying amounts of carbon, typically between 0.2% and 2.1%, which significantly enhances its hardness, strength, and wear resistance compared to pure iron. Pure iron, with its nearly 99.8% iron content, offers excellent ductility, corrosion resistance, and magnetic properties but lacks the mechanical strength required for structural applications. Selecting between carbon steel and pure iron depends on factors such as desired mechanical strength, corrosion resistance, and the specific industrial application.

Carbon Steel vs Pure Iron Infographic

materialdif.com

materialdif.com