Powder-coated iron offers a durable, corrosion-resistant finish that is more resistant to chipping, scratching, and fading compared to painted iron. The powder coating process creates a thicker, more uniform layer that enhances the aesthetic appeal and longevity of iron surfaces. Painted iron, while versatile and easier to apply, often requires more frequent maintenance due to its vulnerability to wear and environmental conditions.

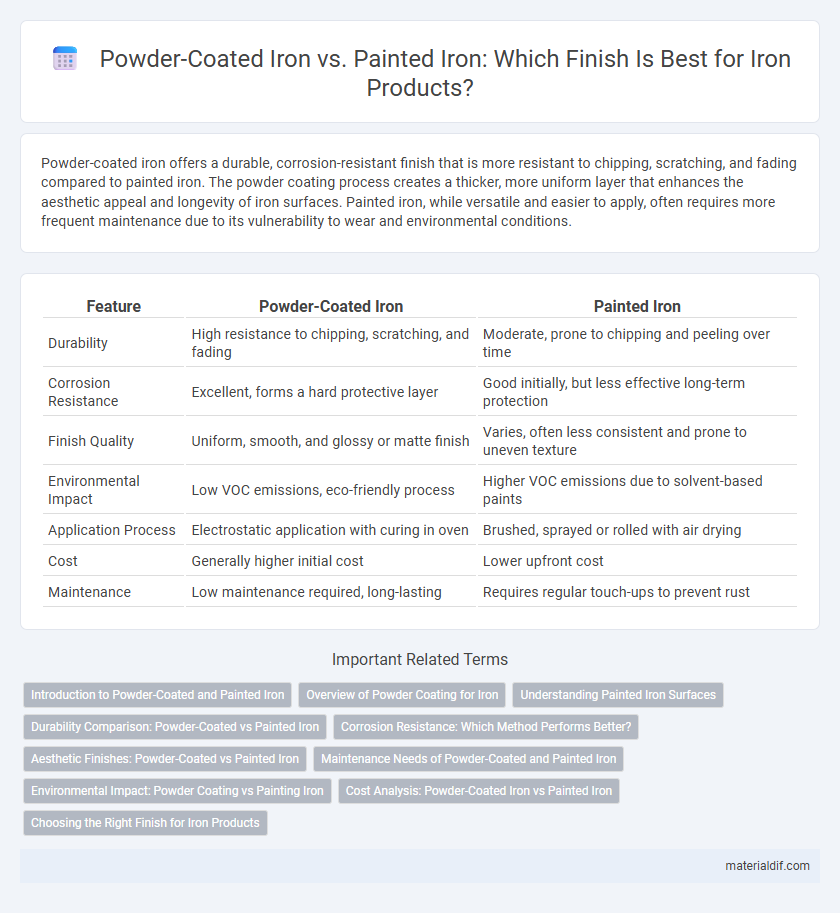

Table of Comparison

| Feature | Powder-Coated Iron | Painted Iron |

|---|---|---|

| Durability | High resistance to chipping, scratching, and fading | Moderate, prone to chipping and peeling over time |

| Corrosion Resistance | Excellent, forms a hard protective layer | Good initially, but less effective long-term protection |

| Finish Quality | Uniform, smooth, and glossy or matte finish | Varies, often less consistent and prone to uneven texture |

| Environmental Impact | Low VOC emissions, eco-friendly process | Higher VOC emissions due to solvent-based paints |

| Application Process | Electrostatic application with curing in oven | Brushed, sprayed or rolled with air drying |

| Cost | Generally higher initial cost | Lower upfront cost |

| Maintenance | Low maintenance required, long-lasting | Requires regular touch-ups to prevent rust |

Introduction to Powder-Coated and Painted Iron

Powder-coated iron features a dry powder applied electrostatically and cured under heat, creating a durable, corrosion-resistant finish that resists chipping, fading, and scratching. Painted iron involves applying liquid paint with brushes or spray, offering a variety of colors and finishes but generally requires more maintenance due to susceptibility to wear and rust. Both finishes enhance iron's aesthetic appeal and protection, with powder coating favored for industrial applications and painted iron commonly used for decorative purposes.

Overview of Powder Coating for Iron

Powder coating for iron involves applying a dry, electrostatically charged powder that adheres to the metal surface before curing under heat, forming a durable and uniform finish. This method provides superior resistance to chipping, corrosion, and fading compared to traditional painting techniques. Powder-coated iron enhances longevity and requires less maintenance, making it ideal for outdoor and industrial applications.

Understanding Painted Iron Surfaces

Painted iron surfaces offer a smooth finish that protects against rust and corrosion by creating a watertight barrier, though they require regular maintenance to prevent chipping and peeling over time. The paint used on iron can vary from oil-based enamels to acrylic formulations, each providing different levels of durability and UV resistance suitable for indoor or outdoor applications. Compared to powder-coated iron, painted iron generally has a thinner protective layer and may need more frequent touch-ups to maintain its appearance and corrosion resistance.

Durability Comparison: Powder-Coated vs Painted Iron

Powder-coated iron offers superior durability compared to painted iron due to its thick, uniform layer that resists chipping, scratching, and corrosion more effectively. The curing process in powder coating creates a hard finish that withstands harsh environmental conditions better than conventional paint, which can degrade and peel over time. As a result, powder-coated iron requires less maintenance and provides longer-lasting protection in outdoor and industrial applications.

Corrosion Resistance: Which Method Performs Better?

Powder-coated iron offers superior corrosion resistance compared to painted iron due to its thicker, more uniform protective layer that prevents moisture and oxygen from penetrating the surface. The powder coating undergoes a curing process that creates a hard finish resilient to chipping, cracking, and fading, significantly extending the lifespan of iron components in harsh environments. Painted iron, while providing an initial barrier against corrosion, tends to chip and peel over time, allowing rust formation and reducing durability.

Aesthetic Finishes: Powder-Coated vs Painted Iron

Powder-coated iron offers a smooth, uniform finish that resists chipping, fading, and scratching, providing a durable and vibrant aesthetic appeal. Painted iron often displays brush strokes or uneven textures, which can add a handcrafted look but tends to be less resilient against environmental wear. The powder-coating process creates a thicker, more consistent layer, enhancing both visual quality and long-term durability compared to traditional paint.

Maintenance Needs of Powder-Coated and Painted Iron

Powder-coated iron offers superior maintenance ease compared to painted iron due to its durable, chip-resistant finish that prevents rust and corrosion with minimal upkeep. Painted iron requires frequent touch-ups and inspections to address peeling and corrosion caused by exposure to moisture and UV rays. The longevity of powder coating reduces the frequency of maintenance, making it a cost-effective choice for outdoor and high-traffic iron applications.

Environmental Impact: Powder Coating vs Painting Iron

Powder-coated iron significantly reduces environmental harm by eliminating the need for solvents and producing less hazardous waste compared to traditional painting, which relies on volatile organic compounds (VOCs) that contribute to air pollution. The curing process in powder coating is more energy-efficient and produces minimal emissions, making it a greener option for iron finishing. Furthermore, powder coating's durability extends the life of iron products, decreasing the frequency of recoating and reducing overall environmental footprint.

Cost Analysis: Powder-Coated Iron vs Painted Iron

Powder-coated iron typically incurs higher upfront costs due to the specialized equipment and materials required but offers greater long-term savings through superior durability and reduced maintenance needs. Painted iron generally has lower initial expenses and a wider range of color options but demands frequent repainting to prevent rust and deterioration, increasing lifetime costs. Evaluating total cost of ownership reveals powder coating as a more cost-effective solution for heavy-duty applications and outdoor exposure.

Choosing the Right Finish for Iron Products

Powder-coated iron offers a durable, long-lasting finish with superior resistance to chipping, scratching, and corrosion compared to traditional painted iron. Painted iron provides a wider range of colors and a smoother texture but requires more maintenance and frequent touch-ups in high-exposure environments. Selecting the right finish depends on the product's intended use, environmental exposure, and maintenance preferences, with powder coating often preferred for outdoor and heavy-use iron products.

Powder-Coated Iron vs Painted Iron Infographic

materialdif.com

materialdif.com