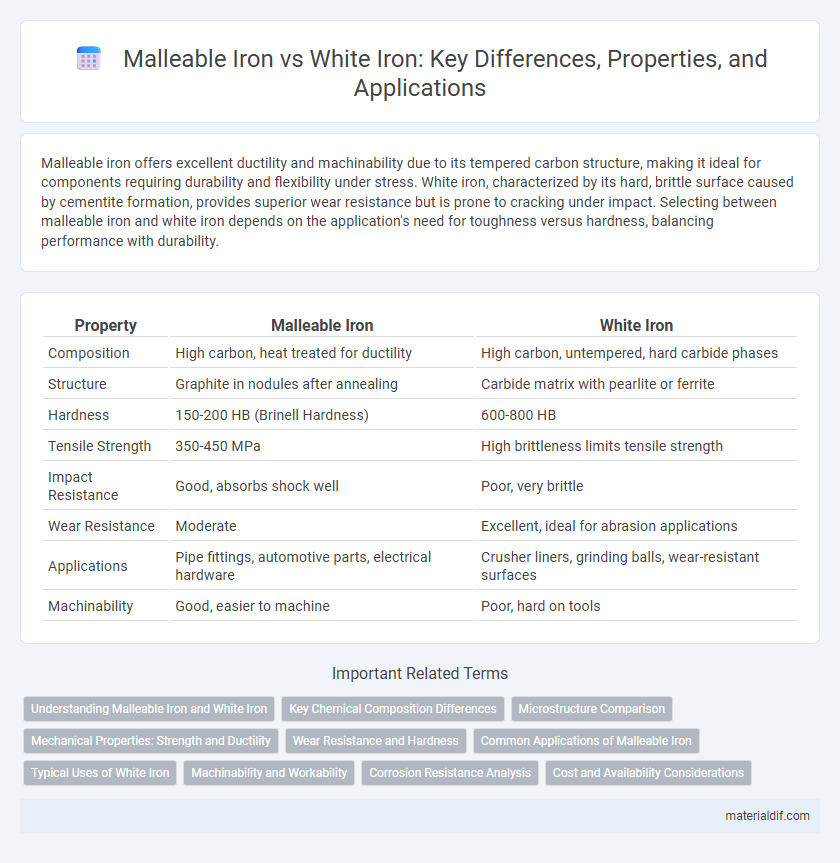

Malleable iron offers excellent ductility and machinability due to its tempered carbon structure, making it ideal for components requiring durability and flexibility under stress. White iron, characterized by its hard, brittle surface caused by cementite formation, provides superior wear resistance but is prone to cracking under impact. Selecting between malleable iron and white iron depends on the application's need for toughness versus hardness, balancing performance with durability.

Table of Comparison

| Property | Malleable Iron | White Iron |

|---|---|---|

| Composition | High carbon, heat treated for ductility | High carbon, untempered, hard carbide phases |

| Structure | Graphite in nodules after annealing | Carbide matrix with pearlite or ferrite |

| Hardness | 150-200 HB (Brinell Hardness) | 600-800 HB |

| Tensile Strength | 350-450 MPa | High brittleness limits tensile strength |

| Impact Resistance | Good, absorbs shock well | Poor, very brittle |

| Wear Resistance | Moderate | Excellent, ideal for abrasion applications |

| Applications | Pipe fittings, automotive parts, electrical hardware | Crusher liners, grinding balls, wear-resistant surfaces |

| Machinability | Good, easier to machine | Poor, hard on tools |

Understanding Malleable Iron and White Iron

Malleable iron is a heat-treated form of white iron that undergoes annealing to transform brittle cementite into clusters of graphite, resulting in improved ductility and impact resistance. White iron is characterized by its hard, brittle structure due to the presence of iron carbide, making it wear-resistant but prone to cracking under stress. Understanding the microstructural differences between malleable and white iron is essential for selecting the appropriate material for applications requiring a balance between strength and flexibility.

Key Chemical Composition Differences

Malleable iron contains higher carbon content, typically ranging from 2.5% to 3.0%, predominantly in the form of temper carbon, which imparts improved ductility and machinability. White iron has a lower carbon content, around 1.8% to 2.5%, with carbon primarily combined as cementite (Fe3C), resulting in a hard, brittle microstructure. The silicon content in malleable iron is generally higher (1.8% to 2.5%) compared to white iron (0.6% to 1.2%), influencing the graphitization process and mechanical properties.

Microstructure Comparison

Malleable iron features a microstructure composed mainly of ferrite or pearlite matrix with graphitic nodules, providing excellent ductility and toughness. White iron's microstructure consists predominantly of cementite (iron carbide) and pearlite, resulting in a hard, brittle material with high wear resistance. The distinct differences in microstructure directly influence their mechanical properties and applications, with malleable iron favoring malleability and white iron excelling in abrasion resistance.

Mechanical Properties: Strength and Ductility

Malleable iron exhibits superior ductility and toughness compared to white iron, making it ideal for applications requiring resistance to impact and deformation. White iron is characterized by high hardness and compressive strength but has low ductility due to its brittle carbide structure. Mechanical properties of malleable iron typically include a tensile strength of 400-700 MPa and elongation of 10-18%, while white iron shows tensile strength around 200-400 MPa with elongation less than 2%.

Wear Resistance and Hardness

Malleable iron exhibits moderate hardness, typically around 180 to 300 HB, which provides good ductility but lower wear resistance compared to white iron. White iron possesses significantly higher hardness, often exceeding 600 HB, due to its cementite-rich microstructure, resulting in superior wear resistance ideal for abrasive environments. The trade-off between the two lies in white iron's brittleness versus malleable iron's toughness and machinability.

Common Applications of Malleable Iron

Malleable iron is commonly used in automotive components such as brackets, gears, and pipe fittings due to its excellent ductility and impact resistance. It is ideal for manufacturing electrical equipment housings and agricultural machinery parts where toughness and flexibility are critical. The material's ability to withstand deformation without cracking makes it suitable for construction hardware and railroad components.

Typical Uses of White Iron

White iron is commonly used in applications requiring high wear resistance and abrasion durability, such as in grinding balls, mill liners, and crusher parts. Its hardness and brittleness make it ideal for environments with intense impact and heavy wear but are less suited for parts needing ductility or machinability. Industries like mining, cement, and power generation frequently utilize white iron components to enhance equipment lifespan under severe operational stress.

Machinability and Workability

Malleable iron exhibits superior machinability and workability compared to white iron due to its ductile microstructure, allowing easier cutting, shaping, and forming processes. White iron's hard and brittle nature, resulting from its cementite-rich composition, limits its machinability and increases tool wear during machining. This makes malleable iron preferable for applications requiring extensive fabrication and modification, while white iron is best suited for wear-resistant components.

Corrosion Resistance Analysis

Malleable iron exhibits superior corrosion resistance compared to white iron due to its microstructure, which contains tempered carbon clusters that reduce brittleness and enhance durability in corrosive environments. White iron, characterized by a hard, brittle microstructure with cementite, is more prone to cracking and corrosion under aggressive conditions. The improved corrosion resistance of malleable iron makes it suitable for applications exposed to moisture and chemicals, such as pipes and outdoor machinery.

Cost and Availability Considerations

Malleable iron generally costs more than white iron due to its complex heat treatment process, which enhances ductility and toughness. White iron is more readily available and cheaper to produce, making it a cost-effective choice for wear-resistant applications. Cost and availability should be key factors when selecting between malleable iron for its mechanical properties and white iron for budget-sensitive, high-hardness uses.

Malleable Iron vs White Iron Infographic

materialdif.com

materialdif.com