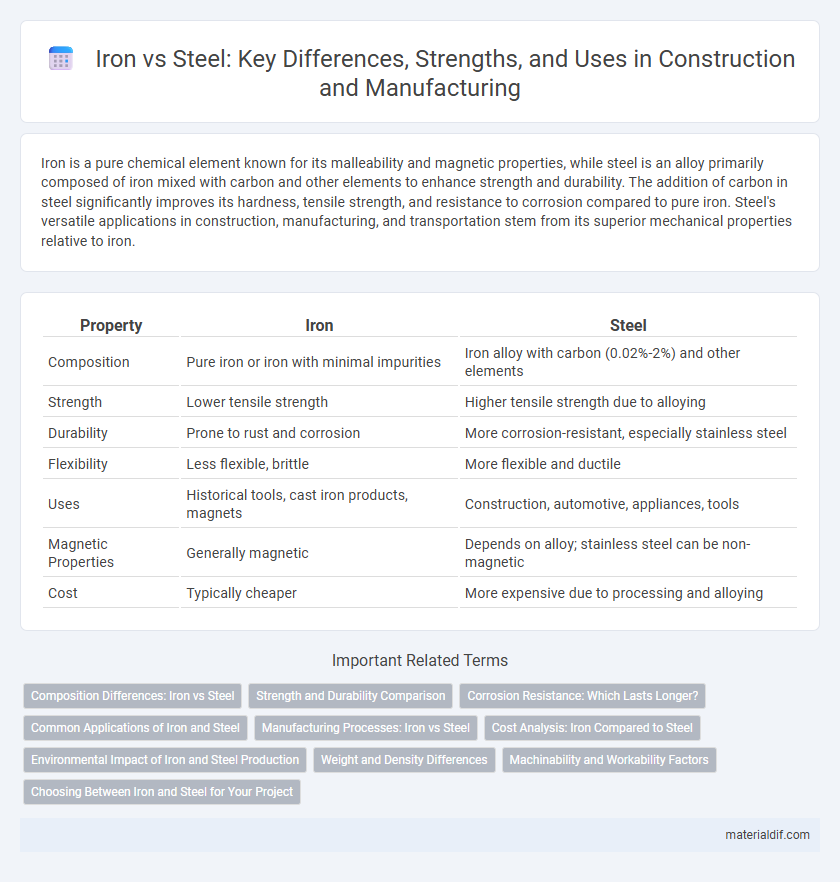

Iron is a pure chemical element known for its malleability and magnetic properties, while steel is an alloy primarily composed of iron mixed with carbon and other elements to enhance strength and durability. The addition of carbon in steel significantly improves its hardness, tensile strength, and resistance to corrosion compared to pure iron. Steel's versatile applications in construction, manufacturing, and transportation stem from its superior mechanical properties relative to iron.

Table of Comparison

| Property | Iron | Steel |

|---|---|---|

| Composition | Pure iron or iron with minimal impurities | Iron alloy with carbon (0.02%-2%) and other elements |

| Strength | Lower tensile strength | Higher tensile strength due to alloying |

| Durability | Prone to rust and corrosion | More corrosion-resistant, especially stainless steel |

| Flexibility | Less flexible, brittle | More flexible and ductile |

| Uses | Historical tools, cast iron products, magnets | Construction, automotive, appliances, tools |

| Magnetic Properties | Generally magnetic | Depends on alloy; stainless steel can be non-magnetic |

| Cost | Typically cheaper | More expensive due to processing and alloying |

Composition Differences: Iron vs Steel

Iron is a chemical element with the symbol Fe and atomic number 26, consisting primarily of pure metallic iron atoms. Steel is an alloy predominantly made of iron but contains carbon (up to 2%) and other alloying elements like manganese, chromium, and nickel, which enhance strength and corrosion resistance. The key compositional difference lies in carbon content; pure iron is soft and ductile, whereas steel's carbon and alloying elements significantly improve hardness and tensile strength.

Strength and Durability Comparison

Iron exhibits lower tensile strength compared to steel, which is an alloy primarily composed of iron and carbon, enhancing its mechanical properties. Steel's microstructure provides superior durability and resistance to wear, making it more suitable for construction and heavy-duty applications. The addition of elements like carbon significantly increases steel's hardness and tensile strength, surpassing the performance of pure iron.

Corrosion Resistance: Which Lasts Longer?

Iron, a pure metal, corrodes quickly due to its high reactivity with oxygen and moisture, forming rust that weakens its structure over time. Steel, specifically stainless steel alloyed with chromium, offers superior corrosion resistance by forming a passive oxide layer that prevents further oxidation. This protective layer ensures steel lasts significantly longer in harsh environments compared to untreated iron.

Common Applications of Iron and Steel

Iron is widely used in construction, manufacturing of machinery, and automotive parts due to its strength and magnetic properties, while steel, an alloy of iron and carbon, dominates in building infrastructure, shipbuilding, and tool production because of its enhanced durability and corrosion resistance. Cast iron is favored for heavy-duty pipes and engine blocks, whereas stainless steel is preferred in kitchen appliances, medical instruments, and aerospace components for its rust-resistant qualities. Both materials are foundational in industrial applications, with steel's versatility making it essential for modern engineering and iron's affordability lending itself to bulk production needs.

Manufacturing Processes: Iron vs Steel

Iron is typically produced through the smelting of iron ore in blast furnaces, where impurities are removed to yield pig iron with high carbon content. Steel manufacturing involves further refining pig iron by controlled addition of carbon and other alloying elements in processes such as basic oxygen steelmaking or electric arc furnace, enhancing strength and flexibility. The key distinction lies in steel's precise chemical composition control and thermal treatments, enabling superior mechanical properties compared to raw iron.

Cost Analysis: Iron Compared to Steel

Iron generally has a lower initial cost compared to steel due to its abundant availability and simpler extraction process. Steel, while more expensive upfront, offers superior strength and durability, often reducing long-term maintenance and replacement costs. Analyzing total lifecycle expenditure reveals steel's higher upfront investment is offset by enhanced performance and extended usability.

Environmental Impact of Iron and Steel Production

Iron production generates significant carbon emissions due to the reliance on coke and coal in blast furnaces, contributing heavily to air pollution and greenhouse gases. Steel production, particularly through electric arc furnaces utilizing recycled scrap, can reduce environmental impact but still involves energy-intensive processes that demand substantial electricity. Innovations in hydrogen-based steelmaking and carbon capture technologies aim to lower the carbon footprint of steel manufacturing, offering promising pathways to mitigate environmental damage.

Weight and Density Differences

Iron has a density of approximately 7.87 grams per cubic centimeter, making it denser than many common metals but lighter than steel alloys used in construction. Steel, an alloy primarily composed of iron with added carbon and other elements, typically exhibits a density ranging from 7.75 to 8.05 grams per cubic centimeter, depending on its specific composition. The weight difference between iron and steel in practical applications is influenced by the steel's enhanced strength-to-weight ratio, allowing for thinner, lighter components while maintaining structural integrity.

Machinability and Workability Factors

Iron exhibits lower machinability compared to steel due to its higher carbon content and brittleness, which cause increased tool wear during cutting processes. Steel's enhanced workability arises from its alloying elements and heat treatment options, allowing for better ductility and toughness, facilitating easier shaping and machining. The machinability of steel can be optimized by controlling carbon levels and adding elements like manganese and chromium, improving cutting efficiency and surface finish quality.

Choosing Between Iron and Steel for Your Project

Iron offers excellent corrosion resistance and a classic aesthetic ideal for decorative or low-stress applications, while steel provides superior strength, durability, and versatility essential for structural projects and heavy-duty uses. Selecting between iron and steel depends on specific project requirements such as load-bearing capacity, environmental exposure, and budget constraints. Steel's alloy composition allows customization for enhanced tensile strength and flexibility, making it the preferred material in construction and engineering.

Iron vs Steel Infographic

materialdif.com

materialdif.com