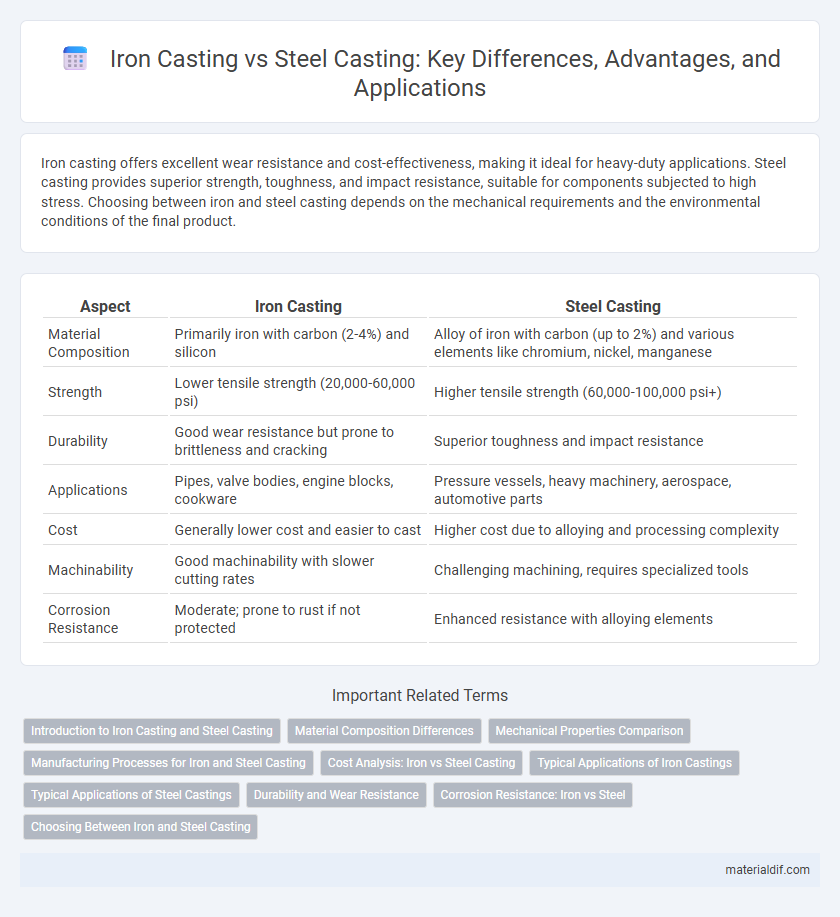

Iron casting offers excellent wear resistance and cost-effectiveness, making it ideal for heavy-duty applications. Steel casting provides superior strength, toughness, and impact resistance, suitable for components subjected to high stress. Choosing between iron and steel casting depends on the mechanical requirements and the environmental conditions of the final product.

Table of Comparison

| Aspect | Iron Casting | Steel Casting |

|---|---|---|

| Material Composition | Primarily iron with carbon (2-4%) and silicon | Alloy of iron with carbon (up to 2%) and various elements like chromium, nickel, manganese |

| Strength | Lower tensile strength (20,000-60,000 psi) | Higher tensile strength (60,000-100,000 psi+) |

| Durability | Good wear resistance but prone to brittleness and cracking | Superior toughness and impact resistance |

| Applications | Pipes, valve bodies, engine blocks, cookware | Pressure vessels, heavy machinery, aerospace, automotive parts |

| Cost | Generally lower cost and easier to cast | Higher cost due to alloying and processing complexity |

| Machinability | Good machinability with slower cutting rates | Challenging machining, requires specialized tools |

| Corrosion Resistance | Moderate; prone to rust if not protected | Enhanced resistance with alloying elements |

Introduction to Iron Casting and Steel Casting

Iron casting involves melting iron, primarily gray, ductile, or malleable iron, and pouring it into molds to create complex shapes with excellent wear resistance and vibration damping properties. Steel casting uses molten steel, often alloyed with elements like chromium or nickel, to produce components with superior strength, toughness, and impact resistance suitable for high-stress applications. Both processes require precise temperature control and mold design, but steel casting generally demands higher temperatures and more intricate metallurgy compared to iron casting.

Material Composition Differences

Iron casting primarily involves the use of cast iron, which contains 2-4% carbon along with varying amounts of silicon, manganese, and sulfur, resulting in a brittle but wear-resistant material. Steel casting, on the other hand, features a much lower carbon content, typically below 2%, combined with elements like chromium, nickel, and molybdenum to enhance strength, ductility, and corrosion resistance. The distinct material compositions dictate the mechanical properties and applications, with cast iron favored for its excellent compressive strength and steel preferred for tougher, more flexible components.

Mechanical Properties Comparison

Iron casting exhibits excellent compressive strength and wear resistance due to its high carbon content, making it ideal for heavy-duty applications. Steel casting provides superior tensile strength, impact resistance, and ductility, attributed to its alloying elements like manganese and chromium. The mechanical properties of steel castings generally surpass those of iron castings in toughness and fatigue resistance, making steel more suitable for dynamic and high-stress environments.

Manufacturing Processes for Iron and Steel Casting

Iron casting primarily involves the use of gray iron, ductile iron, and white iron, which are melted in cupola furnaces or induction furnaces and poured into sand molds for shaping. Steel casting requires higher temperatures, typically using electric arc furnaces or induction furnaces to melt alloyed steel, with precise control over composition for superior mechanical properties, often employing ceramic molds or investment casting methods for intricate designs. Both processes demand controlled cooling rates to influence microstructure and mechanical performance, with steel casting requiring more advanced heat treatment techniques to enhance toughness and strength.

Cost Analysis: Iron vs Steel Casting

Iron casting generally offers lower material and production costs compared to steel casting due to iron's abundance and simpler alloying process. Steel casting involves higher expenses driven by alloy composition, energy-intensive melting, and extended cooling times required for improved mechanical properties. Cost analysis reveals iron casting is more economical for large-volume, less strength-critical parts, while steel casting justifies its premium for components demanding superior strength and corrosion resistance.

Typical Applications of Iron Castings

Iron castings are widely used in automotive engine blocks, machinery bases, and heavy equipment frames due to their excellent wear resistance and vibration damping properties. Gray iron castings are commonly found in pipes, pump housings, and valve bodies because of their good machinability and thermal conductivity. Ductile iron castings serve in agricultural machinery, windmill hubs, and pipe fittings where strength and toughness are critical.

Typical Applications of Steel Castings

Steel castings are typically used in applications requiring high strength, toughness, and resistance to wear and impact, such as heavy machinery components, automotive parts, and pressure vessels. They are preferred in aerospace and power generation sectors for critical structural parts and turbine blades due to their superior mechanical properties. Steel castings also find extensive use in railroad equipment, mining tools, and marine hardware where durability and fatigue resistance are essential.

Durability and Wear Resistance

Iron casting offers superior wear resistance due to its high carbon content and graphite microstructure, making it ideal for applications requiring abrasion resistance. Steel casting provides enhanced durability and toughness, with its alloy composition allowing for better impact resistance and mechanical strength under heavy loads. Choosing between iron and steel casting depends on the specific requirements for longevity and wear performance in industrial applications.

Corrosion Resistance: Iron vs Steel

Iron casting offers moderate corrosion resistance, primarily due to the presence of carbon and other alloying elements that form a protective oxide layer. Steel casting, especially stainless and alloy steels, exhibits superior corrosion resistance as a result of added elements like chromium and nickel, which enhance the formation of a stable, passive oxide film. Applications exposed to harsh environments often favor steel casting for its ability to withstand rust and chemical degradation over time.

Choosing Between Iron and Steel Casting

Choosing between iron casting and steel casting hinges on factors such as strength, durability, and cost-effectiveness. Iron casting offers excellent wear resistance and vibration damping, making it ideal for heavy-duty applications and machinery bases. Steel casting provides superior tensile strength and toughness, suited for components exposed to high stress and dynamic loads, despite generally higher material and production costs.

Iron Casting vs Steel Casting Infographic

materialdif.com

materialdif.com