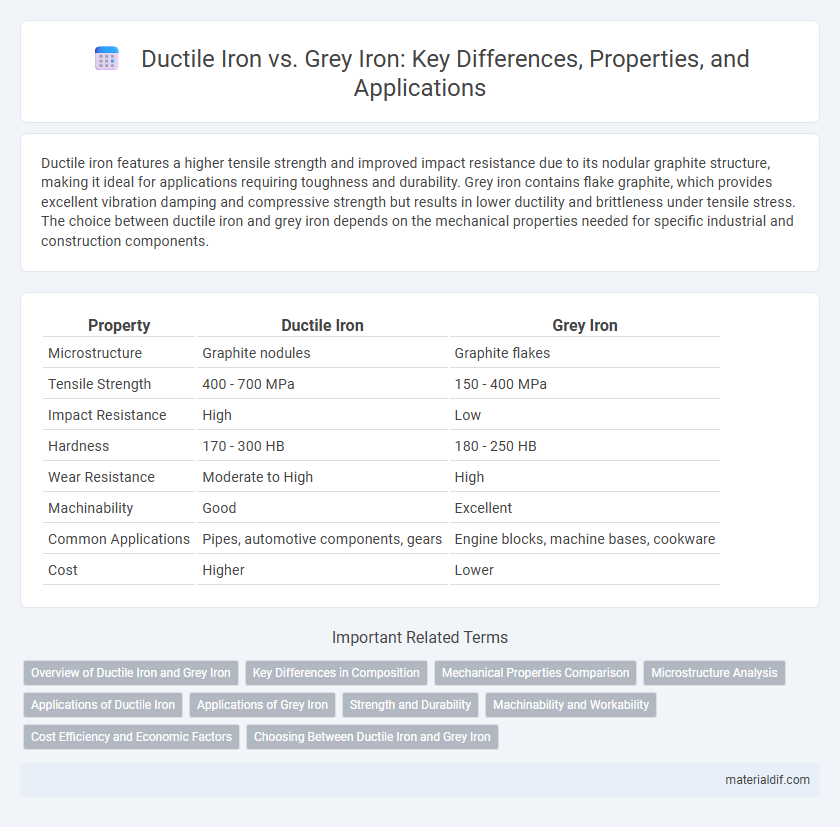

Ductile iron features a higher tensile strength and improved impact resistance due to its nodular graphite structure, making it ideal for applications requiring toughness and durability. Grey iron contains flake graphite, which provides excellent vibration damping and compressive strength but results in lower ductility and brittleness under tensile stress. The choice between ductile iron and grey iron depends on the mechanical properties needed for specific industrial and construction components.

Table of Comparison

| Property | Ductile Iron | Grey Iron |

|---|---|---|

| Microstructure | Graphite nodules | Graphite flakes |

| Tensile Strength | 400 - 700 MPa | 150 - 400 MPa |

| Impact Resistance | High | Low |

| Hardness | 170 - 300 HB | 180 - 250 HB |

| Wear Resistance | Moderate to High | High |

| Machinability | Good | Excellent |

| Common Applications | Pipes, automotive components, gears | Engine blocks, machine bases, cookware |

| Cost | Higher | Lower |

Overview of Ductile Iron and Grey Iron

Ductile iron, known for its enhanced tensile strength and ductility, contains nodular graphite which improves impact resistance and elongation properties. Grey iron features flake-like graphite structures, resulting in excellent compressive strength and vibration damping but lower tensile strength. Both materials are widely used in automotive and construction industries, with ductile iron preferred for components requiring toughness and flexibility, while grey iron is chosen for its castability and machinability.

Key Differences in Composition

Ductile iron contains nodular graphite formed by adding small amounts of magnesium or cerium, resulting in enhanced tensile strength and ductility compared to grey iron, which has flake graphite that induces brittleness. The matrix of ductile iron is generally pearlitic or ferritic, providing superior impact resistance, while grey iron mainly consists of pearlite and ferrite that promote good castability but lower mechanical properties. These compositional differences yield distinct microstructures, making ductile iron preferable for applications requiring flexibility and toughness, whereas grey iron suits components needing excellent vibration damping and compressive strength.

Mechanical Properties Comparison

Ductile iron exhibits superior tensile strength, typically ranging from 60,000 to 120,000 psi, compared to grey iron's lower range of 20,000 to 60,000 psi, due to its spheroidal graphite microstructure. Its higher elongation percentage, often above 10%, indicates enhanced ductility and impact resistance, whereas grey iron has minimal elongation, usually under 1%, making it more brittle. Ductile iron also offers better fatigue strength and toughness, making it ideal for dynamic and high-stress applications, while grey iron is favored for its excellent compressive strength and vibration damping in static loads.

Microstructure Analysis

Ductile iron features a microstructure characterized by spherical graphite nodules, enhancing its tensile strength and impact resistance compared to grey iron, which contains flake-like graphite structures that promote brittleness and lower mechanical performance. The microstructural differences directly influence the mechanical properties, with ductile iron offering improved ductility and fatigue resistance due to the nodular graphite disrupting crack propagation. Analysis under microscopy reveals that the matrix composition--typically pearlitic or ferritic--also plays a significant role in tailoring the hardness and toughness of both iron types.

Applications of Ductile Iron

Ductile iron is widely used in automotive components such as crankshafts, gears, and suspension parts due to its excellent strength, toughness, and fatigue resistance. Its application extends to water and sewage pipes, where its superior corrosion resistance and ductility provide durability under high pressure and harsh environmental conditions. Industrial machinery parts, including valve bodies and pump housings, commonly utilize ductile iron for its ability to withstand heavy loads and abrasive wear.

Applications of Grey Iron

Grey iron is widely used in automotive engine blocks, pipes, and heavy machinery due to its excellent vibration damping and machinability. Its graphite structure provides good thermal conductivity and resistance to wear, making it ideal for brake discs and pump housings. The material's brittleness limits its use in applications requiring high tensile strength but suits components subjected to compressive loads.

Strength and Durability

Ductile iron exhibits superior tensile strength and impact resistance compared to grey iron due to its spheroidal graphite structure, which enhances ductility and toughness. Grey iron, characterized by flake-shaped graphite, offers good compressive strength but is more brittle, making it less durable under dynamic or tensile loads. The enhanced microstructure of ductile iron leads to greater durability and fatigue resistance, making it ideal for heavy-duty applications requiring high strength and long service life.

Machinability and Workability

Ductile iron offers superior machinability due to its nodular graphite structure, which reduces tool wear and allows for faster cutting speeds compared to grey iron. Grey iron, characterized by its flake graphite, exhibits lower machinability but provides excellent castability and vibration damping, making it suitable for applications requiring complex shapes. Workability in ductile iron is enhanced by its higher tensile strength and elongation, facilitating welding and forming processes that are more challenging with the more brittle grey iron.

Cost Efficiency and Economic Factors

Ductile iron offers superior tensile strength and impact resistance compared to grey iron, often resulting in longer-lasting components that reduce replacement frequency and maintenance costs. Grey iron, with its simpler manufacturing process and lower raw material expenses, generally incurs lower initial costs, making it economically favorable for applications with less structural demand. Evaluating overall cost efficiency requires balancing grey iron's affordability against ductile iron's durability benefits and potential life-cycle savings.

Choosing Between Ductile Iron and Grey Iron

Choosing between ductile iron and grey iron depends primarily on the required mechanical properties and application environment. Ductile iron offers superior tensile strength, impact resistance, and ductility due to its spherical graphite structure, making it ideal for automotive components and heavy machinery requiring durability. Grey iron, characterized by flake graphite, provides excellent vibration damping and compressive strength, making it suitable for engine blocks, pipes, and cookware where brittleness and ease of machining are acceptable trade-offs.

Ductile Iron vs Grey Iron Infographic

materialdif.com

materialdif.com