Electrogalvanizing provides a thinner, more uniform zinc coating on iron surfaces, making it ideal for applications requiring precise thickness and smooth finishes. Hot-dip galvanizing involves immersing iron in molten zinc, resulting in a thicker, more durable coating that offers superior corrosion resistance in harsh environments. Choosing between these methods depends on the balance between coating durability and surface smoothness needed for specific uses.

Table of Comparison

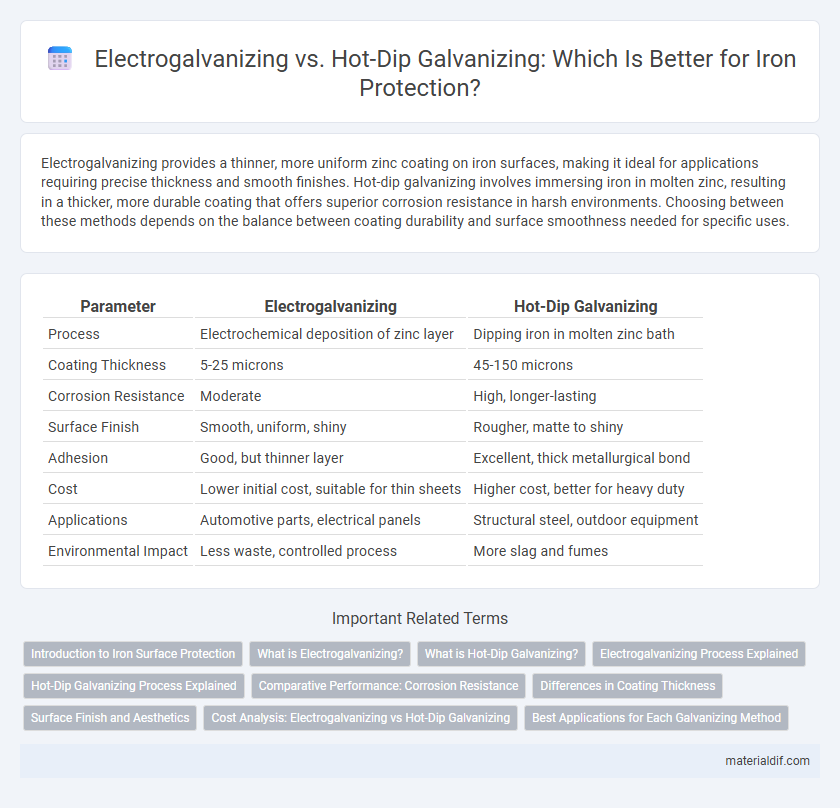

| Parameter | Electrogalvanizing | Hot-Dip Galvanizing |

|---|---|---|

| Process | Electrochemical deposition of zinc layer | Dipping iron in molten zinc bath |

| Coating Thickness | 5-25 microns | 45-150 microns |

| Corrosion Resistance | Moderate | High, longer-lasting |

| Surface Finish | Smooth, uniform, shiny | Rougher, matte to shiny |

| Adhesion | Good, but thinner layer | Excellent, thick metallurgical bond |

| Cost | Lower initial cost, suitable for thin sheets | Higher cost, better for heavy duty |

| Applications | Automotive parts, electrical panels | Structural steel, outdoor equipment |

| Environmental Impact | Less waste, controlled process | More slag and fumes |

Introduction to Iron Surface Protection

Electrogalvanizing applies a thin, uniform zinc coating through an electrolytic process to protect iron surfaces from corrosion, offering better aesthetic finish and precise thickness control. Hot-dip galvanizing involves immersing iron in molten zinc, creating a thicker, more robust zinc-iron alloy layer that provides superior long-term corrosion resistance in harsh environments. Both methods enhance iron durability, but hot-dip galvanizing is preferred for heavy-duty applications due to its thicker protective barrier.

What is Electrogalvanizing?

Electrogalvanizing is a process that applies a thin layer of zinc to steel or iron through electroplating, creating a corrosion-resistant barrier. This method offers precise coating control and a smooth, uniform surface finish, making it ideal for automotive and appliance manufacturing. The zinc coating thickness typically ranges from 5 to 25 microns, enhancing the metal's durability without significantly altering its dimensions.

What is Hot-Dip Galvanizing?

Hot-dip galvanizing is a corrosion protection process where iron or steel is submerged in molten zinc at approximately 450degC, creating a robust metallurgical bond between the zinc coating and the base metal. This method produces a thick, durable layer that offers superior resistance to abrasion and harsh environmental conditions compared to electrogalvanizing. Hot-dip galvanized steel is widely used in construction, automotive, and infrastructure applications due to its long-lasting protection against rust and corrosion.

Electrogalvanizing Process Explained

Electrogalvanizing involves applying a thin layer of zinc to iron or steel through an electrolytic process, ensuring precise coating thickness and a smooth, uniform finish ideal for corrosion resistance in automotive and appliance industries. Unlike hot-dip galvanizing, which relies on immersing steel in molten zinc, electrogalvanizing uses an electric current to deposit zinc ions, resulting in a cleaner surface with less spangle and reduced risk of distortion. This method offers superior control over coating quality and thickness, making it suitable for components requiring tight dimensional tolerances and excellent paint adhesion.

Hot-Dip Galvanizing Process Explained

Hot-dip galvanizing involves immersing iron or steel in molten zinc at approximately 450degC (842degF), creating a robust, corrosion-resistant coating through metallurgical bonding. This process produces a thick, durable layer with excellent abrasion resistance, ideal for outdoor structures exposed to harsh environments. Hot-dip galvanizing forms distinct zinc-iron alloy layers that enhance long-term protection against rust and corrosion compared to the thinner coating from electrogalvanizing.

Comparative Performance: Corrosion Resistance

Electrogalvanizing provides a thinner, more uniform zinc coating ideal for applications requiring precise tolerances, but its corrosion resistance is generally lower compared to hot-dip galvanizing. Hot-dip galvanizing creates a thicker, metallurgically bonded zinc-iron alloy layer that offers superior long-term protection against harsh environmental conditions and abrasion. In highly corrosive environments, hot-dip galvanizing significantly extends the lifespan of iron products by providing robust resistance to oxidation and rust formation.

Differences in Coating Thickness

Electrogalvanizing typically produces a thinner zinc coating ranging from 5 to 25 microns, providing a smooth, uniform finish ideal for precise applications. Hot-dip galvanizing applies a thicker layer, generally between 45 to 150 microns, offering superior corrosion resistance and durability in harsh environments. The significant difference in coating thickness directly impacts the lifespan and protective qualities of the galvanized iron products.

Surface Finish and Aesthetics

Electrogalvanizing produces a smooth, uniform zinc coating with a bright, shiny surface finish ideal for applications requiring aesthetic appeal and precision. Hot-dip galvanizing results in a thicker, more rugged coating with a matte, textured appearance, offering superior corrosion resistance but less visual refinement. Choosing between the two depends on balancing desired surface aesthetics with environmental durability requirements.

Cost Analysis: Electrogalvanizing vs Hot-Dip Galvanizing

Electrogalvanizing typically incurs higher upfront equipment and operational costs due to specialized electrical processes but offers thinner, more uniform zinc coatings ideal for precision steel parts. Hot-dip galvanizing involves lower initial costs with simpler batch processing, providing thicker, more durable coatings suited for heavy-duty protection against corrosion. Cost efficiency depends on application requirements, coating thickness, and production volume, with electrogalvanizing favored for smaller, high-volume runs and hot-dip galvanizing preferred for large structural steel components.

Best Applications for Each Galvanizing Method

Electrogalvanizing is ideal for applications requiring a thin, uniform zinc coating with excellent surface finish, such as automotive parts and electrical components, due to its precise control and minimal distortion. Hot-dip galvanizing suits heavy-duty and outdoor structures like bridges, guardrails, and pipelines, providing thick, durable corrosion resistance in harsh environments. Choosing between these methods depends on factors like exposure conditions, coating thickness, and mechanical requirements.

Electrogalvanizing vs Hot-Dip Galvanizing Infographic

materialdif.com

materialdif.com